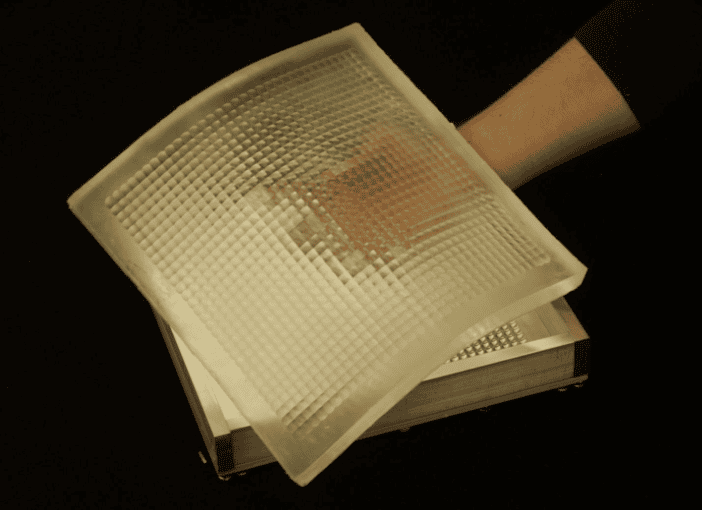

[Image above] Columbia Engineering researchers have developed a novel sheet camera that can be wrapped around everyday objects to capture images that cannot be taken with one or more conventional cameras. Credit: Columbia Computer Vision Laboratory, 2016/Columbia Engineering

Flexible electronics are the future.

From smartphones to wearables, tech companies and researchers are innovating electronics that are thinner, more durable, and can bend without breaking.

And some researchers are really ‘stretching’ their inspiration. At the end of last year, we reported on a new stretchable, wearable sensor made from something you find stuck to the bottom of your shoe on an unlucky day—chewing gum.

Most recently, researchers from Columbia University’s School of Engineering and Applied Science are developing a new flat, thin camera that is so flexible it can be wrapped around objects to capture images that can’t be taken with conventional cameras—even with multiple camera setups—according to a university news release.

The team designed and fabricated a flexible lens array that adapts its optical properties when the sheet camera is bent, the release explains. And it’s this optical adaptation that allows the sheet camera to produce high-quality images when bent or wrapped around an object.

“Cameras today capture the world from essentially a single point in space,” Shree K. Nayar, T.C. Chang Professor of Computer Science at Columbia Engineering and lead researcher, says in the release. “While the camera industry has made remarkable progress in shrinking the camera to a tiny device with ever increasing imaging quality, we are exploring a radically different approach to imaging. We believe there are numerous applications for cameras that are large in format but very thin and highly flexible.”

Check out this video produced by Columbia Engineering that demonstrates the research.

Credit: Columbia Engineering; YouTube

If this imaging system could be scaled up cheaply, the technology could be wrapped around anything to capture wide, seamless images with unusual fields of view, the release explains—everything from street poles to furniture, cars, and clothing.

But for this flexible camera to work, two technologies are needed—a flexible detector array and a thin optical system that can project a high-quality image on the array, according to the release.

To address this dual technological need, the team developed an “adaptive lens array made of elastic material that enables the focal length of each lens in the sheet camera to vary with the local curvature of the sheet in a way that mitigates aliasing in the captured images,” the release explains. “This inherent optical adaptation of the lens is passive, avoiding the use of complex mechanical or electrical mechanisms to independently control each lens of the array.”

To create the passively adaptive lens array, the team optimized geometry and material properties of the lens and used silicone to create the prototype. Through various tests, the team found that the lens array had the ability to produce high image quality over a wide range of deformations of the sheet camera.

The team says this novel “flex-cam” design sets the stage for development of cameras the size of a credit card that a photographer could simply bend to control field of view.

The Columbia team includes research engineer Daniel Sims and postdoctoral researcher Yonghao Yue. Sims will present the work at the International Conference on Computational Photography at Northwestern University in Evanston, Ill., May 13–15.

Check out the team’s project page to learn more about the research.

Author

Stephanie Liverani

CTT Categories

- Glass

- Manufacturing

- Material Innovations

- Optics

Spotlight Categories

- Member Highlights