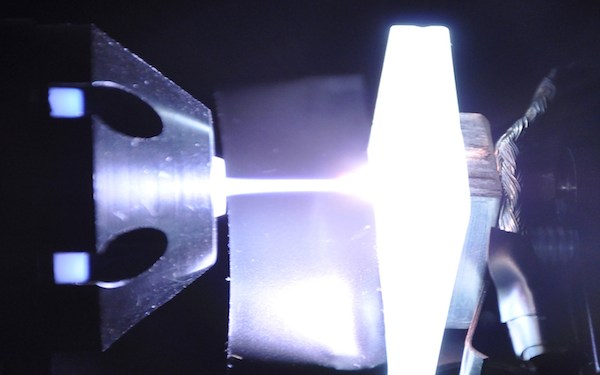

Lasers team up with plasma to fabricate microstructures in glass more efficiently. Credit: Fraunhofer IST

Optical components made of microstructured glass are integral to most of today’s technologies, including cellphones and cameras. Read: those components are numerous, ubiquitous, and very important.

While microstructures are usually created with lasers, a new technology developed at the Fraunhofer Institute (Göttingen, Germany) combines lasers with atmospheric pressure plasma beams to create those microstructures more efficiently.

“By using this laser-plasma hybrid technology, we have succeeded in conducting the structuring using far less energy,” says scientist Wolfgang Viöl in a Fraunhofer press release.

Standard laser microstructuring uses ultraviolet or infrared lasers, which can be expensive and imprecise, respectively.

To marry plasma to laser in the new tech, the researchers redesigned the plasma source to produce cold plasma in a very thin beam so that it could be coupled with a laser. “The effect of this plasma beam is that the laser radiation can be absorbed better, so that we can conduct the processing with relatively low laser energy,” says Viöl in the press release.

The team reports the laser-plasma duo works on various glasses, leading to the submission of a patent application for the tech. No word yet on how well it performs in comparison to current methods, or whether it has specific limitations.

According to the release, “At the next stage, the Göttingen-based scientists will also extend their hybrid approach to other materials—such as metals, ceramics or synthetics. The simultaneous use of laser and plasma could also make new processing or coating processes possible—even for temperature-sensitive materials such as textiles and paper.”

The team will present their work at the Optatec optical technology trade show in Frankfurt next week.

Author

April Gocha

CTT Categories

- Electronics

- Energy

- Glass

- Material Innovations

- Optics