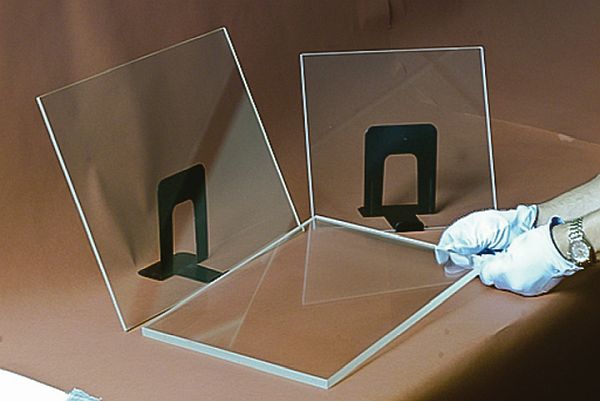

[Image above] Single-crystal and polycrystalline ceramics are used as the gain medium in lasers, or the material used to amplify the power of light. Credit: Ruff, Shutterstock

One impressive thing about our expanding universe is how much of it exists at scales or under conditions beyond our innate comprehension. Human eyes can only take in a limited amount of information, with extremely small or faraway phenomena beyond our capacity to observe naturally. Factor in electromagnetic signals outside the visible spectrum—and processes that only occur in hazardous environments—and it becomes obvious how little we really see.

Fortunately, human ingenuity has enabled the development of optical instruments that can measure and observe the many things we cannot directly perceive. In today’s CTT, we look specifically at the expanding applications of polycrystalline ceramics in optical instruments, including recent breakthroughs in materials science, the observations they have made possible, and improvements that are on deck for the future.

Coming full circle: Processing advancements revive the use of crystalline materials in optics

As early as 700 BCE, the people of ancient Egypt and Mesopotamia conducted some of the first experiments in the science of optics. Their attempts to emulate the remarkable optical properties of water involved carefully polished crystalline lenses, primarily quartz, which were used as realistic eyes in statues and for magnifying objects.

Starting in the 1300s CE, glass started to be used instead of polished quartz in spectacles. Although the optical properties of these first glasses were variable, soon glass started outperforming the traditional quartz because processing advancements improved lens quality.

The Nimrud lens is a 3,000-year-old portion of rock crystal that is believed to have been used as a magnifying glass. Credit: Geni, Wikimedia (CC BY-SA 4.0)

The reason that glass performed better than polished quartz comes down to lattice structure. As noted in the Book of Optics, a seven-volume treatise composed by the medieval Arab scholar Ibn al-Haytham in the early 1000s CE, light travels in straight lines until it interacts with matter. Because light particles are extremely small, many crucial interactions occur at the nano and microscales, i.e., at the size of a material’s lattice structure.

In crystalline materials such as quartz, the lattice structure consists of highly ordered, repeating atomic arrangements. If these arrangements are consistent throughout the entire structure, the material is called a single crystal. If the structure consists of differently oriented arrangements, the material is called polycrystalline, and the interfaces between each differently oriented region are called grain boundaries.

The grain boundaries in polycrystalline materials are significant barriers that can scatter incoming light, which is why single-crystal quartz was used for early lenses. However, although the uninterrupted lattice structure of single crystals leads to less scattering, naturally formed single crystals often contain impurities and imperfections that reduce their optical properties compared to glass, which lacks a long-range lattice structure.

It was more than 900 years after the publication of the Book of Optics that scientists started imaging and understanding the effect of lattice structure on optical properties. But by then, polished quartz lenses were a distant memory in favor of advanced optical glasses. (Besides its well-known role in revolutionizing scientific labware and baking containers, borosilicate glass also played a significant role in the field of optics.)

By the mid-20th century, single crystals started finding widespread usage in optical applications again because improved processing methods removed the imperfections that caused undesirable light scattering. Advancements were also made in producing transparent polycrystalline ceramics, such as the so-called Yttralox ceramic developed by General Electric in 1966, which was intended as an envelope for streetlights due to its high-temperature resistance.

The possibility of transparent polycrystalline ceramics was exciting because these materials can offer enhanced fracture toughness as well as higher temperature and chemical resistances compared to glass. However, scientists doubted transparent polycrystalline ceramics could reach the transmittance performance necessary for high-end optical applications due to the existence of grain boundaries.

In 1995, a groundbreaking study was published to announce the (previously considered impossible) fabrication of a polycrystalline ceramic with optical properties on par with single crystals. This milestone achievement paved the way for other polycrystalline ceramic developments, moving them beyond simple transparency to optical-grade capabilities.

Nowadays, polycrystalline ceramics can be found in a wide range of optical applications, with some more established than others. In the sections below, we will look at some of the most developed applications to date.

Polycrystalline ceramics in lasers

One of the most visible applications (pardon the pun) of both single and polycrystalline ceramics in optics are lasers. Starting from the very first laser in 1960, single crystals were used as the laser’s gain medium, i.e., the material used to amplify the power of light. Today, single-crystal neodymium-doped yttrium aluminum garnet (Nd:YAG) is one of the most common gain mediums.

Thanks to the aforementioned improvements in fabricating polycrystalline ceramics, these materials are now used as laser gain mediums as well. In fact, modern polycrystalline Nd:YAG allows for essentially the same laser efficiency as single-crystal Nd:YAG.

Additional benefits of polycrystalline ceramic gain mediums include highly scalable manufacturing processes compared to single crystals and more opportunities for doping to achieve greater control over optical properties.

Prototype of an optical isolator using terbium yttrium oxide ceramic (right) in comparison with a commercial optical isolator based on terbium gallium garnet single crystal (left). Credit: Akio Ikesue

Besides the gain medium, other laser components, such as optical isolators (which allow light transmission in only one direction), are made from single crystals as well. But there are opportunities for polycrystalline ceramics to be used in these components, too.

Both single-crystal and polycrystalline ceramic lasers are used in many of the same applications, for example, industrial machining, laser eye surgery, and high-power rangefinding. Another emerging possibility for polycrystalline ceramic lasers are light imaging, detection, and ranging (LiDAR) systems for self-driving cars.

(LiDAR is also making waves in archeology by aiding in the discovery of lost cities in Central America and Southeast Asia, where buildings are quickly buried under the fast-growing jungle.)

Polycrystalline ceramics for windows

Compared to the stationary windows in your home or office, car windows are designed with greater durability to keep passengers safe when driving at high speeds in dangerous road conditions. Meanwhile, the vehicle windows used in even harsher environments, such as deep-sea voyages and battlefields, have especially stringent technical requirements, for example, increased impact and pressure resistance.

The transparent ceramics aluminum oxynitride and magnesium aluminate spinel are providing a new generation of armor-like windows that can match these requirements in both military and commercial applications. The existence of these polycrystalline aluminum compounds are especially exciting for fans of Star Trek IV: The Voyage Home, as they are the real-life counterparts of the imaginary elemental “transparent aluminum” from that movie.

Example of transparent aluminum oxynitride window manufactured by Surmet Corp. Credit: Ramisetty et al., ACerS Bulletin (March 2013)

Windows for space exploration vehicles is one area where polycrystalline ceramics may really shine. The extreme environments found on other planets in our solar system—as well as within the stars, dust clouds, and asteroid belts that populate the universe—are opportunities for new materials science applications. Polycrystalline ceramics can readily withstand many of these extreme conditions, and so may one day help make human space travel safer.

Besides vehicle windows, another opportunity for polycrystalline ceramics is as diagnostic windows to observe material transformations in high-temperature furnaces and nuclear reactors. These materials provide the extremely high tolerance against heavy irradiation with practically no swelling that nuclear experiments require.

Polycrystalline ceramics as lenses

As noted previously, the improved processing techniques available today make the application of polycrystalline ceramics as lenses possible. In the early 2000s, Casio Inc., in conjunction with its parent company, Casio Computer Co., used the transparent Lumicera ceramic developed by Murata Manufacturing to create lenses for digital cameras.

Besides that example, polycrystalline ceramics are not commonly used as lenses today. However, as noted in the window section, the durability of polycrystalline ceramics means they may serve well as objective lenses intended for harsh environments. These ceramics are also known for good infrared transmission properties, so they could be used as lenses in night-vision goggles and other infrared optics.

Though not a lens, polycrystalline ceramics have been used as mirrors in telescopes. The European Space Agency’s Herschel telescope used silicon carbide to make the largest single-component telescope reflector ever put into space.

Future innovations in optical polycrystalline ceramics

As processing methods continue to improve, the use of polycrystalline ceramic optical components in ultrahigh-power lasers and other extreme environments will likely grow as well. It could also enable their use in emerging fields, such as photonic computing and gradient refractive index (GRIN) lenses.

Undoubtedly, polycrystalline ceramics will be a robust field of exploration for many years to come, providing many new uses in optical applications.

Author

Becky Stewart and Lisa McDonald

CTT Categories

- Education

- Material Innovations