[Image above] Credit: Pitsanu Kraichana / Shutterstock

Great cities’ stories are written in brick. It is the material that shaped skylines, built neighborhoods, and served as the urban fabric for generations. Bricks and cities have been inextricably joined for millennia, ever since sunbaked mud was found to be structurally sound.

With October being Manufacturing Month, a nationwide initiative to celebrate the importance and ingenuity of modern manufacturers, it is an ideal time for us to explore the symbiotic relationship between bricks and cities, from the ancient world to the future of urban design.

This exploration will take place through a special three-part series. The first part, which you are reading now, looks at the role local geology plays in the emergence of our modern brick cities. The second part, which publishes October 28, takes a trip back in time to show how simple sun-dried bricks were used to create the very first urban centers. The third part, which publishes November 11, describes the evolving uses for this ancient material and emphasizes our responsibility to preserve its urban legacy.

For this first part, we will use the story of New York City and the Hudson River Valley varved clays as a primary example of modern brick city development. But first, to set the stage, we need to talk about the geology of clay (again, yes; it’s my happy place).

The foundation and the fuel: A geological partnership

Clay and coal are frequently found together because they formed in the same environments—ancient swamps and bogs. Coal seams are the fossilized remains of vast forests and vegetation that grew in low-lying, swampy areas during the Carboniferous period, approximately 350 to 300 million years ago. These environments were stagnant, anoxic, and often waterlogged.

The soil on which this vegetation grew formed a fine-grained, clay-rich layer called underclay or fireclay. This soil was leached of calcite, illite, chlorite, and feldspar by the acidic, waterlogged conditions and the extensive root systems of the plants. Leaching enriched the clay in kaolinite, which gives fireclay its unique properties.

Over time, the swamps were buried by layers of new sediment, such as sand and silt. The organic swamp vegetation was compressed and heated, transforming it into coal. The underlying clay layer was also compressed and sometimes hardened into a sedimentary rock (shale).

Image showing the geological layers of soil, coal, and rock at an open anthracite mine. Credit: Parilov / Shutterstock

The right place at the right time: Hudson River clay

The rise of New York City to become one of the greatest cities in the world is a serendipitous combination of geology and geography. The abundant glacial clay deposits along the Hudson River’s banks created the perfect conditions for brickmaking on an almost unimaginable scale. The high-quality anthracite coal used as kiln fuel (and later, brick additive) that was mined in northeastern Pennsylvania became easy to access after the completion of the Delaware and Hudson Canal, in 1828.

Additionally, the river provided an easy way to deliver the bricks quickly to where they were needed. The center of this industrial hub was Haverstraw, N.Y., approximately 40 miles north of New York City. Haverstraw was at one time known as the Brickmaking Capital of the World, and today it is home to the Haverstraw Brick Museum.

I had the pleasure of visiting the museum on Aug. 28, 2025, where I got a behind-the-scenes tour of their existing collections, a fascinating history lesson, and a teaser view of their future expansion plans. It was there that the idea of theming this series around the rise and evolution of cities was born.

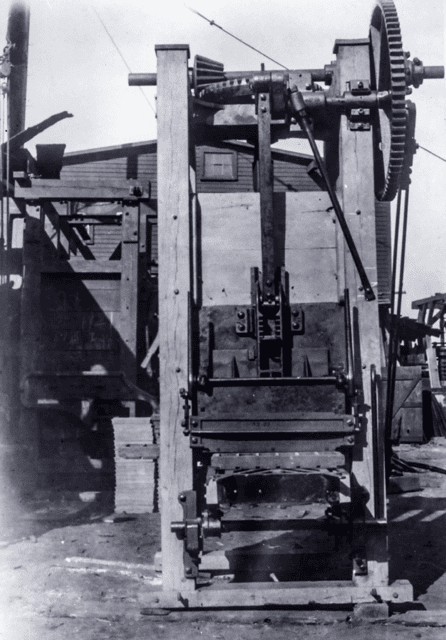

Workers using the Ver Valen automatic brickmaking machine at the Excelsior Brickyard in Haverstraw, N. Y., circa 1900. From the Dan DeNoyelles Collection of the Haverstraw Brick Museum Archives. © Haverstraw Brick Museum. Republished with permission.

From artisanal to industrial

The First Industrial Revolution was to brick like the assembly line was to cars. New technologies such as steam-powered machinery and continuous kilns made bricks abundant, transforming them from a traditional handmade material into the foundation of the modern urban landscape.

The Hudson Valley brickworks, centered at Haverstraw, were right at the heart of the transformation. The brickyards each specialized in one of three types of brick: infrastructure bricks (such as for tunnels and subways), structural bricks for external walls, or nonstructural façade bricks. Infrastructure bricks were the densest and most expensive type, and the nonstructural façade bricks were the least expensive.

Photo of Richard A. Ver Valen’s automatic brickmaking machine, circa 1900. From the Dan DeNoyelles Collection of the Haverstraw Brick Museum Archives. © Haverstraw Brick Museum. Republished with permission.

Several important brickmaking innovations came from Haverstraw. The first was James Wood’s 1836 patent for adding coal dust to the bricks, allowing all of the bricks in a typical scove kiln arrangement the ability to fire evenly, as they would be heated from the inside as well as the exterior. This innovation also reduced the time required to fire the bricks from approximately 14 days to 7 days and increased the energy efficiency of the kiln.

The second innovation was Richard A. Ver Valen’s steam-powered brick press, patented in 1852. This innovation is what cemented Haverstraw’s persona as the Brickmaking Capital of the World because the machine was exported globally to grow the brickmaking industry. In the Hudson Valley alone, hundreds of millions of bricks were produced annually in the late 19th and early 20th centuries. Brickmaking became an easy path to wealth and spread westward across the expanding United States, thanks in large part to the Erie Canal.

Because of brick’s commercial value, some of the Haverstraw brickmakers dug deep into the Hudson River’s bed and in tunnels that extended underneath the town to extract more clay as the surface deposits were depleted. This increased extraction weakened the stability of the slopes above the river, upon which the town was built. The inevitable result was a deadly landslide in 1906, the scar of which is still visible today.

Bricks and urban giants: (Re)Building New York City

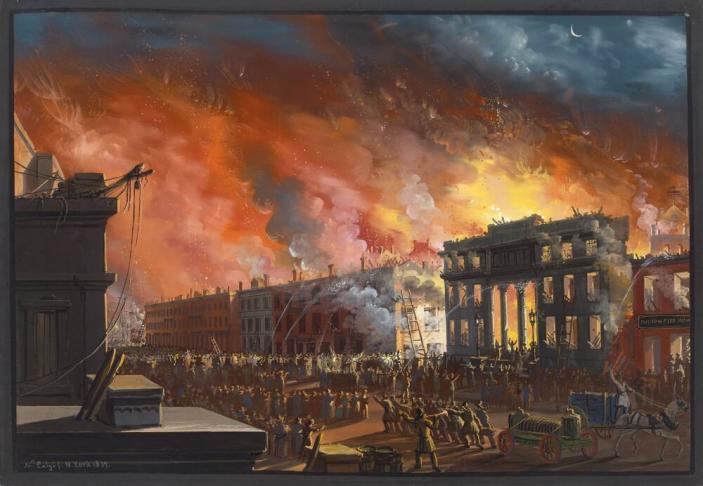

Despite the dangers, demand for brick continued to increase. The first few decades of the 19th century were a period of tremendous urban growth. Great cities sprawled across the landscape, supported by global trade. (New York City’s population increased by 60% in the decade after the opening of the Erie Canal in 1825.) Most of these cities’ early growth consisted of wooden buildings because lumber was plentiful. And each of these global cities suffered a catastrophic fire: Paramaribo (1821), Canton (now called Guangzhou; 1822), New York (1835), London (1861), Chicago (1871), and Cochin (now called Kochi; 1889).

Two of these fires had notable impacts on U.S. society. The Great New York Fire of 1835 became the impetus for insurance regulations, and the Chicago Fire of 1871 led to revamped fire and building codes. The first full week of October is National Fire Prevention Week in the U.S., which commemorates the dates of the fire (October 8–10).

In the aftermath of the New York City fire, the city mandated that all new buildings must be made of fire-proof materials. To meet the demand, mass-produced bricks from the Hudson River Valley were loaded onto barges and floated down the river. Haverstraw bricks became the structural backbone for countless iconic buildings and infrastructure, including the Croton Aqueduct and Central Park’s bridges.

The Great New York Fire of 1835 broke out on December 16 and raged for more than 15 hours on the coldest day in 36 years (17 degrees below zero). The fire is depicted in this gouache (opaque watercolor) painting by Italian–American painter Nicolino Calyo. Credit: The Bayou Bend Collection of The Museum of Fine Arts, Houston (Public domain)

Global brick cities

The uniformity and durability of bricks enabled rapid urban expansion in cities wherever clay was plentiful, giving rise to so-called “brick cities” all over the world. Some well-known examples include Munich, Germany; London, England; Hanoi, Vietnam; St. Louis, Mo.; and Philadelphia, Pa.

St. Louis and Philadelphia, like New York City, benefited from their geologic setting. Their locations directly shaped their identities as major brick-producing centers.

In St. Louis, coal and clay were both found in abundance. The city had a massive brick industry in the late 19th and early 20th centuries, making it one of the most productive brick-making cities in the world. This industry proved critical after the city suffered its own great fire in 1849. The city’s landscape today is defined by its brick architecture, a direct result of the postfire rebuilding.

Although cities such as St. Louis and Philadelphia built their brick foundations in the 18th and 19th centuries, today the story of brick is a global one, centered in Asia. China and India are major producers, with India alone manufacturing an estimated 250 billion bricks annually to meet the demands of its fast-growing economy and urban population. We’ll be looking at today’s brick innovations in Part 3 of this series.

The legacy of a universal material

By leveraging local geology and industrial innovation, cities such as New York, Chicago, and St. Louis were able to build on an unprecedented scale, often in response to catastrophic fires. This industrialization cemented brick as the foundation of the modern metropolis.

In the next part of this series, which publishes October 28, we will take a leap back in time. Long before machines and steam power, simple sun-dried bricks were used to create the very first urban centers. We will explore how ancient civilizations such as those in Mesopotamia and the Indus Valley used brick to build monumental structures, lay out sophisticated cities, and create the foundations of civilization itself.

We thank the Haverstraw Brick Museum for their insightful and educational content, which guided the writing of this series.

Author

Becky Stewart

CTT Categories

- Construction

- Education