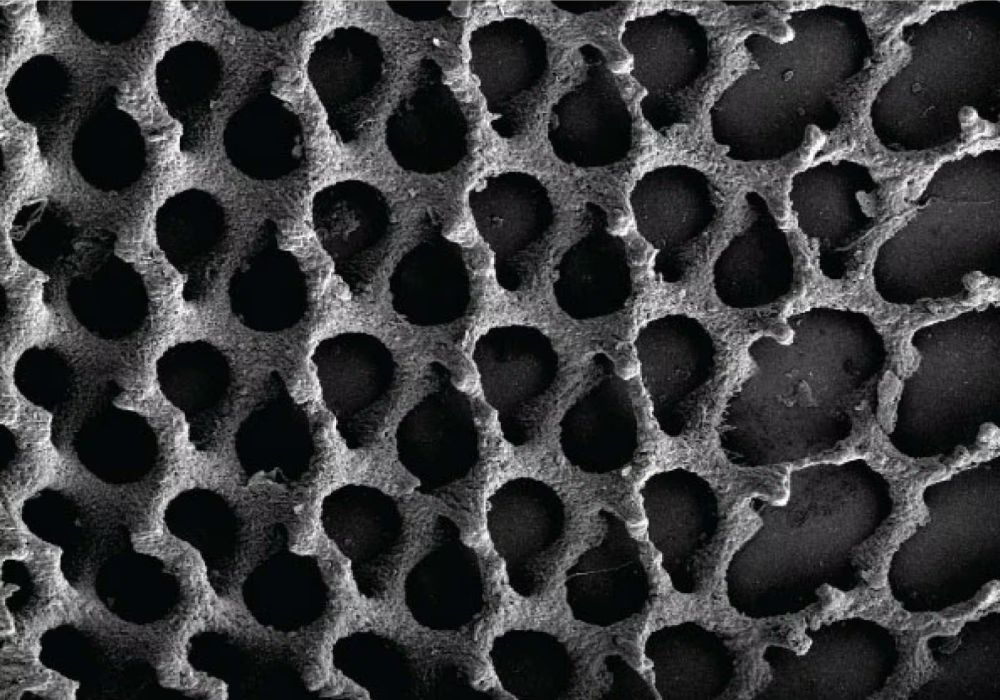

[Image above] The diabolical ironclad beetle is tough—in addition to the ability to play dead and a rough exoskeleton that resembles a rock, this little beetle is hiding some interesting secrets within its exoskeleton that could help design more robust fasteners. Credit: Jesus Rivera; University of California, Irvine

Here is a fact about life on our planet that I find astounding—beetles constitute more than 25% of known animal life and almost 40% of all insects roaming the earth.

That’s a lot of beetles. Upwards of 350,000 known species, in fact, exist in nearly all habitats (save marine and polar regions), and they adapted to subsist off of a vast array of different diets.

In addition to having adapted rather well to life on earth, one of the secrets to the success of beetles seems to be that these kind of insects don’t often go extinct.

Yet while all beetles seem to be a bit stubborn in terms of survival, there is one particular species of beetle that stands out for taking its toughness to an entirely different level—the diabolical ironclad beetle, Phloeodes diabolicus.

The diabolical ironclad beetle not only plays dead and has a rough textured exoskeleton that blends in with surrounding rocks, but its survival mechanisms also include an exoskeleton that is legendary for being tough. Entomologists know that the beetle’s exoskeleton is so tough that it can bend the steel pins used to mount specimens of insects for display. And the insect can even get up and walk away unharmed after being run over by an automobile—see for yourself below.

Credit: Learning from Nature, YouTube

But what makes this little beetle so diabolically tough? A new study reveals some of the secrets the beetle stores in its tough exoskeleton, secrets that could develop biomimetic materials and structures to join dissimilar materials in more robust ways.

The team—an international group of scientists from University of California Riverside, University of California Irvine, Purdue University, University of Texas at San Antonio, Tokyo University of Agriculture and Technology, and Lawrence Berkeley National Laboratory—used advanced microscopy and spectroscopy to reveal that a mixture of macrostructure and microstructure elements combine to make the diabolical ironclad beetle’s exoskeleton incredibly strong.

Materially speaking, their analysis of the beetle’s exoskeleton shows that it is composed of aligned chitin fibers in a protein-rich matrix. That matrix has a higher protein content than other comparable beetles, which the scientists speculate contributes to the diabolical ironclad beetle’s incredible ability to withstand crushing by forces up to 39,000-times its body weight.

The team specifically focused on a part of the insect’s exoskeleton called the elytra, which are two hard, protective blades that armor a beetle’s back to protect a set of more delicate wings used for flying. Elytra act like a protective outer door, opening to allow a beetle’s wings to extend in flight and then closing to protect the delicate structures when not in use. (To be clear, the diabolical ironclad beetle has lost the ability to fly, but it maintains a set of protective elytra.)

Beyond the material composition of the insect’s exoskeleton, the study also shows that macrostructural elements of the elytra also contribute to the beetle’s toughness—namely, a series of lateral support structures along the perimeter of the insect’s body, and a robust suture that holds the two elytra together.

First, the lateral supports. Located around the edges of the insect’s body, these structures help buoy the elytra when the insect is being compressed, preventing its body cavity from being crushed. Stress concentrates around the perimeter of the insect’s shell, so these structures provide critical support precisely where it’s needed most.

The team’s analysis of these structures using computed tomography shows that the diabolical ironclad beetle incorporates three different types of support structures around its shell.

The most robust support structures, located near the front of the insect’s body, have an architecture that interlocks and stiffens under strain. These structures are closest to the insect’s internal organs, so the interlocking structure provides maximum support to help prevent the insect’s guts from being squished when it’s compressed.

Supports further back along the shell don’t interlock but rather feature a latching design, while supports still further toward the back of the insect’s shell are entirely free-standing and feature no mechanical connection.

Although the team characterized three types of support structures, it’s important to note that these different structures are not disparate elements. Rather, they seamlessly transition from one to the next along the length of the beetle’s shell, creating variable stiffness gradients.

This strategy of varying stiffness increases the exoskeleton’s toughness by not simply allowing it to withstand pressure—it also strategically deflects energy away from critical areas, like where the internal organs are located, to other areas of the exoskeleton that can better dissipate energy without catastrophic failure to the beetle.

A crosssection of the medial suture that joins the diabolical ironclad beetle’s elytra, revealing the interlocking puzzle piece structure. Credit: Jesus Rivera; University of California, Irvine

In addition to these differential lateral supports, the beetle’s two elytra are also stitched together by a robust connection that resembles interlocking puzzle pieces. This architecture binds the elytra together, providing support at an otherwise weak location of a joint in the exoskeleton. This structure also incorporates a unique layered microstructure that prevents localized stresses, another way the beetle strategically dissipates energy to resist crushing.

“When you break a puzzle piece, you expect it to separate at the neck, the thinnest part,” senior author David Kisailus says in a UCI press release. “But we don’t see that sort of catastrophic split with this species of beetle. Instead, it delaminates, providing for a more graceful failure of the structure.”

To confirm that these various scales of structure and architecture account for the beetle’s toughness, Kisailus and the team mimicked the beetle’s ironclad structures in 3D-printed composite fasteners and tested their mechanical strength in the lab. These tests showed that the beetle-based structures were slightly stronger but exhibited significantly increased energy displacement to avoid catastrophic failure compared to commercial aerospace fasteners.

The information from the mechanical tests extends beyond just expanding our knowledge of nature. It can help develop biomimetic strategies that translate into tougher materials design as well as engineering of robust structures. For instance, the scientists note that such information could be used to design more robust strategies to join different materials, which remains an engineering challenge in aerospace applications and beyond.

“These designs could be useful in joining other dissimilar engineering materials such as plastics and metals. Such materials are currently joined by mechanical fastening, which adds weight and introduces stress concentrators that degrade the strength and can lead to fatigue issues, corrosion and early failure,” the authors write in the paper.

They also note that tuning material parameters could further enhance these structures, providing exciting possibilities for robust new strategies to engineer structures as tough as diabolical beetles.

The paper, published in Nature, is “Toughening mechanisms of the elytra of the diabolical ironclad beetle” (DOI: 10.1038/s41586-020-2813-8).

Author

April Gocha

CTT Categories

- Biomaterials & Medical