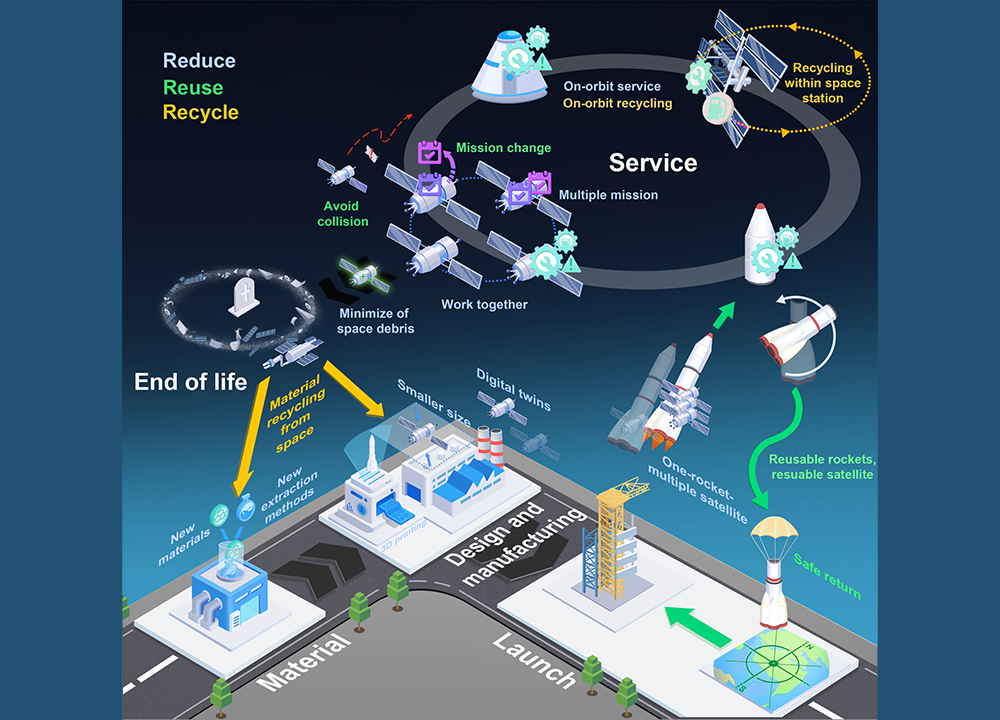

[Image above] Schematic outlining the implementation of circular economy strategies—reduce (light blue), reuse (green), and recycle (yellow)—across five key stages in the space sector: materials, design and manufacturing, launch, service, and end of life. Credit: Yang et al., Chem Circularity (CC BY 4.0)

Many people look toward the stars with wonder, but that view is being increasingly clouded both physically and figuratively by the growing problem of space debris.

Space debris or “junk” is any human-made object in Earth’s orbit that no longer serves a useful purpose. These objects include defunct satellites and lost tools, and when accounting for fragments produced from collisions, the amount of space debris currently in orbit is in the millions of pieces.

Steering clear of debris is becoming increasingly challenging as private space entrepreneurs launch unprecedented numbers of new satellites into orbit. Some governments and organizations are attempting to combat this challenge by “designing for demise,” or creating satellites that burn up in the atmosphere after decommissioning. But the effectiveness of this method is slowly waning as greenhouse gases cause the atmosphere to contract, which reduces its ability to pull old satellites and other debris down to altitudes where they will burn up.

To ensure long-term stability of the growing space economy, we will need to move away from the linear production–consumption paradigm. Instead, “the integration of circular economy principles—centered on reducing inputs, reusing functional components, and enabling recycling—offers a viable pathway for alleviating both orbital and environmental burdens,” University of Surrey researchers write in a recent open-access paper.

The authors frame their analysis around five key stages in the space sector: materials, design and manufacturing, launch, service, and end of life.

- Materials: Reduction-oriented approaches include the development of novel materials and alternative extraction techniques.

- Design and manufacturing: Strategies such as 3D printing, miniaturization, and the use of digital twins contribute to reduction.

- Launch: Reduction is enabled by multipayload launches, whereas reusability is advanced through recoverable rockets and satellites.

- Service: Reduction measures include on-orbit servicing (such as refueling and repair), multimission satellites, and cooperative satellite constellations that fulfill complex tasks collectively. Reuse is supported by mission reconfiguration and collision-avoidance systems that enable safe re-entry and repeated deployment. The recycle strategy is represented by in-orbit recycling technologies and closed-loop material reuse within space stations.

- End of life: Reduction is pursued through active minimization of space debris, whereas recycling involves recovery and reintegration of in-orbit materials into Earth-based manufacturing via novel reprocessing methods.

Table showing the current state and potential of embedding reduce, reuse, and recycle principles into each stage of the space sector. Credit: Yang et al., Chem Circularity (CC BY 4.0)

To successfully adopt circular economy principles in the space sector, the authors note that advanced digital technologies, such as artificial intelligence, can help space companies improve resource efficiency, minimize waste, and maximize the reuse and life cycle of materials and spacecraft.

“Although data acquisition in the space sector remains highly challenging and publicly accessible datasets are extremely limited, it is undeniable that the integration of AI and data analytics has significantly advanced the development of space sustainability,” they write.

The biggest factor in successful implementation of these principles, though, is adopting a whole-system approach to the challenge rather than focusing on individual components or processes, the authors state.

“A whole-system approach is essential to capturing the interdependencies between material flows, energy efficiency, and life-cycle processes in the space sector. This perspective enables the identification of synergies across stakeholders and promotes comprehensive strategies for resource optimization,” they write.

The open-access paper, published in Chem Circularity, is “Resource and material efficiency in the circular space economy” (DOI: 10.1016/j.checir.2025.100001).

Author

Lisa McDonald

CTT Categories

- Aeronautics & Space

- Market Insights

Related Posts

Solid-state batteries turn heads at CES 2026

January 29, 2026