[Image above] Credit: Robert Thompson, Cambridge University

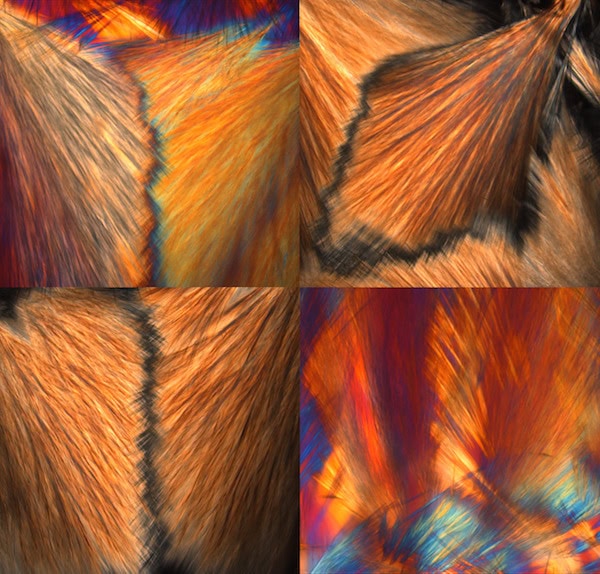

Polarized light microscopy reveals that devitrite crystals, grown on heat-treated soda-lime-silica glass, form intricately beautiful fan-shaped needles. Credit: H. Butt, University of Birmingham.

Haider Butt must believe in the old adage that one man’s trash is another man’s treasure. Butt, a lecturer in microengineering and nanotechnology at the University of Birmingham (United Kingdom), recently discovered a treasure plucked right from the glass industry’s trash.

Devitrification (crystallization in glass) is the source of “stones” in glass, which have long been considered a defect by glass manufacturers. Called simply “devitrite,” the most prominent crystal form in commercial soda–lime–silica glass has a triclinic crystal structure.

Although pretty to look at, the overlapping fans of needles of devitrite crystals have long been discarded trash of the glass industry. They used to plague glassmakers who wanted to produce transparent glass, but once they figured out how to keep devitrite at bay, the unwanted but beautiful crystals were mostly put out of sight and out of mind.

Butt’s recent work, published in ACS Nano, details the use of devitrite as a novel optical diffuser. Just how he stumbled upon devitrite, as he explains in an email, is an interesting and funny story.

While training at Cambridge University (United Kingdom), Butt went to the Materials and Metallurgy department to meet a friend. While milling around the reception area waiting for his friend, Butt noticed a poster decorating the department’s walls. The vivid colors of devitrite crystals caught Butt’s eye and seems to have started turning some wheels. Interested and curious, Butt snapped a picture of the poster, met his friend, and moved on.

When he later searched for devitrite online and found a dearth of information about the material’s optical properties, Butt was intrigued. As he explains, “As a researcher, I am always looking for something that has never been done before because I believe that doing something new is easier and involves less work compared to repeating and improving something that has already been done.” Work smarter, not harder.

Hooked by the mysterious intrigue of devitrite, Butt contacted the author of the poster, Kevin Knowles. Knowles, a materials scientist at Cambridge, obliged and provided Butt with some samples of devitrite. Knowles is second author on the ACS Nano paper and also has a paper on the growth of devitrite crystals soon to be published in the Journal of the American Ceramic Society. The paper further characterizes devitrite crystal growth and alleviates some published activation energy discrepancies, and it is entitled “Growth of Devitrite, Na2Ca3Si6O16, in Soda–Lime–Silica Glass” (DOI: 10.1111/jace.12922).

Knowles is quite familiar with the “glass trash,” as he has published a handful of papers to characterize devitrite and its properties. His work shows that although devitrite has long had the status of an unwanted material, “its crystal growth behaviour from glass, the fine detail of its spherulitic morphology, and the nature of its twinning behaviour…make devitrite a fascinating silicate-based material to continue to study in its own right,” states one of Knowles’ earlier papers. Knowles continues, explaining his original connection to devitrite, in an email:

“The original impetus for this work was the need to have samples some twenty years ago to show the phenomenon of crystal growth for our first year Cambridge undergraduate practicals in Crystalline Materials (as it then was) for the Natural Sciences Tripos. Float glass, when suitably devitrified, turns out to be an excellent material in which to show this as a function of temperature, and our undergraduates still use these samples. The Swift articles from JACerS in 1947 were inspirational in this respect, and I should also acknowledge Kingery, Bowen and Uhlmann who drew my attention to Swift’s work (‘Introduction to Ceramics’, p.356-7). The student who undertook the experiments all those years ago commented on the cloudiness of the devitrified material, but it was Haider who realised that this could be put to good use as a diffuser.”

Observing the striking colors that devitrite crystals reveal under polarized light, Butt realized the discarded stuff must be “doing something interesting with light,” as he says. He and his colleagues went to the lab to induce formation of devitrite crystals in soda-lime-silica float glass by heating at 900°C. They then tested the crystals’ diffusion of a red laser onto a semitransparent hemispherical screen.

Their simple but informative test revealed that devitrite strongly diffuses light at wide angles. The authors write in the paper, “In common with other ceramics and minerals, the refractive indices of devitrite are wavelength-dependent, so that different optical wavelengths undergo different phase retardance.”

Because many current optical diffusers are nanofabricated with sophisticated methods, they are expensive. Devitrite, however, may be able to replace those diffusers because it’s easy to produce at low cost. Potential applications are varied and include optical imaging, photovoltaics, photolithography, and diffusers for thermal energy medical devices, visual display systems, and LEDs, the authors write in the paper.

Butt explains that their research is just beginning. He says in an email, “We already have a commercial partner who is interested in using devitrite as a diffuser for LED light sources in museums. We are also working towards controlled growth of devitrite so that we can control the beam widths of the diffused light.”

As Knowles says in an email, “Haider and I really hope that the interest in devitrite as an optical diffuser will lead to renewed interest in this material.”

The paper is titled “Devitrite-based optical diffusers” (DOI: 10.1021/nn500155e).

Author

April Gocha

CTT Categories

- Basic Science

- Glass

- Material Innovations

- Optics

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026