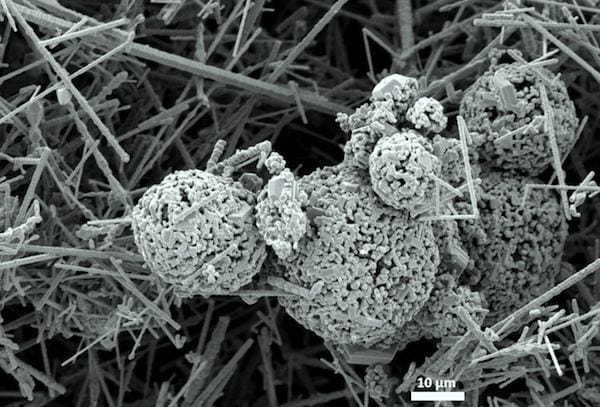

[Image above] SiC spheres deposited on fiber networks during the processing of SiC microlattices. Porous SiC materials must be sintered in controlled atmospheres that sometimes result in deposition of SiC with various morphologies from the gas phase. Credit: Imperial College, London–CASC

“There are only two lasting bequests we can hope to give our children. One of these is roots, the other, wings,” said 18th century philosopher, writer, and statesmen Johann Wolfgang von Goethe.

The same might be said of funding agencies.

In 2008, the British Engineering and Physical Research Council (EPSRC) established the Centre for Advanced Structural Ceramics at Imperial College, London, through its fourth “science and innovation call.” EPSRC is the United Kingdom’s primary agency for funding research in the engineering and physical sciences. The concept behind the five-year, £5.5 million program was to provide “roots” of support while the Centre established itself and built a consortium of “wings” comprising industry members and universities.

According to Eduardo Saiz Gutierrez, professor at Imperial College and director of CASC, “The goal was to address the lack of critical mass of U.K. expertise in the fundamental understanding of structural ceramics, which underpin key areas of the economy, including energy generation, aerospace, defence, transport, and healthcare.” The first director of the Centre was Bill Lee, professor at Imperial and future president of The American Ceramic Society (2017–18).

CASC started from almost nothing—the first tasks were to renovate antiquated labs and acquire new equipment. Now CASC is a fully functioning, state-of-the-art multidisciplinary center with industry consortium partners in the U.K. and “in the abroad.” Industry partners include companies such as Rolls Royce, Morgan Technical Ceramics, DSTL, and Reaction Engines. A sampling of non-U.K. consortium members includes companies such as Kerneos and Asahi Glass Company.

The Centre has built a “hub and spoke” network of academic partners, too, with university partners in the U.K., as well as the United States, Belgium, Spain, Germany, France, Israel, China, and Italy. Today, CASC has more than 30 students and postdoctoral researchers working on advanced structural ceramics that are supervised by Saiz, Lee, and two other faculty—Finn Giuliani and Luc Vandeperre.

As its name describes, CASC research focuses on advanced structural ceramics. However, the research cuts widely across applications and materials. For example, researchers study bioinspired composites, ultrahigh temperature ceramics, glass matrix composites for optomechanical devices, graphene, age hardening of coatings, concrete containing clay brick waste, and more.

Processing research figures prominently into the research programs. Work on silicon carbide, for example, investigates hot pressing and spark plasma sintering with an aluminum nitride sintering aid. The CASC annual report (pdf) presents highlights of advanced structural ceramic research discoveries. The annual report also provides information about membership fees for joining the consortium and benefits that accrue at various participation levels.

Outreach is a key aspect of the CASC mission. Saiz says, “CASC also organizes different activities to promote scientific dissemination and ceramics education, such as a summer school on ceramics, lectures, specialized workshops, industry days, and the Richard Brook Prize for the best Ph.D. thesis on ceramics in the U.K.”

The fifth Industry Day on campus on January 23, 2015 will bring leading experts from academia and industry together for technical presentations and consortium building. (See announcement details here.)

Attendees at CASC’s third summer school in 2013. Credit: Imperial College, CASC

Author

Eileen De Guire

CTT Categories

- Basic Science

- Material Innovations