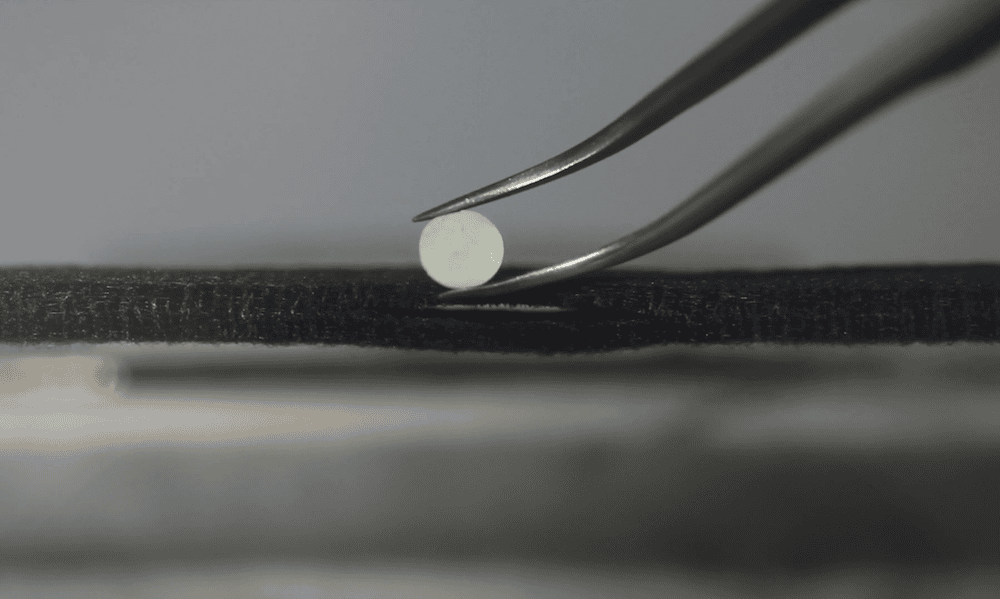

[Image above] In a new study, researchers at the University of Maryland and colleagues describe an ultrafast high-temperature ceramic sintering method that could overcome previous sintering limitations. Credit: Liangbing Hu’s group at University of Maryland

When it comes to developing new ceramic and glass compositions, one of the challenges lies in simply identifying possible compositions to pursue. Machine and deep learning methods are poised to help tremendously in this regard in the coming years—they already are for oxide glasses—but there still lies the challenge of creating these new materials after identification.

For ceramics, the conventional ceramic sintering process often requires hours of processing time, which limits how quickly new compositions can be experimentally tested. This process causes particular problems for development of ceramic-based solid-state electrolytes (SSEs)—a technology considered critical for improving battery energy efficiency and safety—because of lithium and sodium’s severe volatility during sintering.

Researchers have devoted substantial effort to developing innovative sintering technologies, such as microwave-assisted sintering and spark plasma sintering (SPS). However, both these processes face limitations.

“Microwave-assisted sintering of ceramics often depends on the microwave absorption properties of the materials or uses susceptors,” researchers write in a recent paper. “The SPS technique requires that dies are used to compress the ceramic while sintering, which makes it more difficult to sinter specimens with complex three-dimensional (3D) structures.”

They add that while more recently developed methods such as flash sintering, photonic sintering, and rapid thermal annealing (RTA) display a high heating rate, “flash sintering conditions depend strongly on the electrical characteristics of the material … Photonic sintering temperatures are normally too low to sinter ceramics … [and RTA] can only provide a sintering temperature of up to ~1200°C with expensive commercial equipment.”

In the new paper, researchers from the University of Maryland (UMD) and colleagues from Virginia Tech and the University of California (San Diego and Los Angeles) propose a new sintering method—ultrafast high-temperature sintering (UHS)—which they say overcomes many of these limitations.

Senior author Liangbing Hu, Herbert Rabin Distinguished Professor of the Department of Materials Science and Engineering and director of the Center for Materials Innovation at UMD, describes the method in a UMD press release.

“With this invention, we ‘sandwiched’ a pressed green pellet of ceramic precursor powders between two strips of carbon that quickly heated the pellet through radiation and conduction [~103 to 104°C/min], creating a consistent high-temperature environment [up to ~3,000°C] that forced the ceramic powder to solidify quickly,” Hu says.

Compared to other methods, the researchers note UHS:

- Prevents volatile evaporation and undesirable interdiffusion due to short sintering time, unlike conventional sintering,

- Allows general and rapid synthesis and sintering of a broad range of ceramic (and metallic) materials by decoupling intrinsic properties of the material (such as the electric response) from the process, unlike flash sintering,

- Enables the potential for scalable, roll-to-roll sintering of ceramics because the precursor film can quickly pass through the heating strips, and

- Is compatible with 3D printing of ceramic precursors, unlike SPS.

Example of the UHS method in practice. Credit: Liangbing Hu’s group at University of Maryland

In an email, ACerS Fellow Jian Luo, coauthor and professor of materials science and engineering at UC San Diego, explains how previous work on flash sintering and RTA helped lead to the new method.

“This ‘ultrafast high-T sintering’ works somewhat similar to the ‘flash sintering’ pioneered by Prof. Rishi Raj, who first demonstrated the possibility of sintering ceramics in seconds with an applied electric field/current,” Luo says. “A prior mechanistic study at UCSD suggested that the ultrahigh heating rate is a key factor to enable ultrafast sintering by demonstrating that similar densification rates can be achieved for ZnO specimens via (1) flash sintering and (2) rapid thermal annealing (IR heating w/o an E field) with similar heating rates of ~200 K/s. A similar conclusion was also achieved by Prof. Richard Todd and co-workers via another independent study of YSZ at about the same time.”

In regard to the new method, Luo adds, “I think that this work not only represents a technology breakthrough in ultrafast sintering technologies because of its general applicability, but also is scientifically significant in verifying and understanding the critical roles of ultrahigh heating rates in fast sintering.”

The UHS technology is being commercialized through HighT-Tech LLC, a UMD spinoff company with a focus on high-temperature technologies.

The paper, published in Science, is “A general method to synthesize and sinter bulk ceramics in seconds” (DOI: 10.1126/science.aaz7681).

Author

Lisa McDonald

CTT Categories

- Manufacturing

- Material Innovations