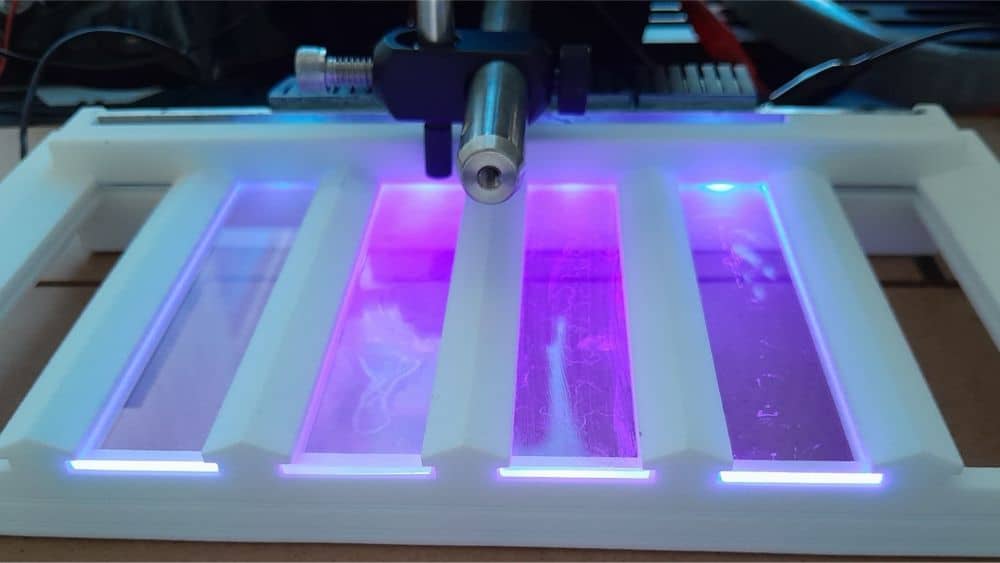

[Image above] A new ultraviolet-emitting glass can reduce visible biofilm growth by 98%. Credit: Mariana Lanzarini-Lopes, University of Massachusetts Amherst

Even though Disney may want to forget about the most expensive traditionally animated feature it ever made, many of my friends cite “Treasure Planet” as their favorite Disney movie.

This space-based retelling of the iconic novel “Treasure Island” tells the story of teenager Jim Hawkins’ journey across a parallel universe as a cabin boy aboard a glittering space galleon. But as Hawkins quickly finds out, the shiny hull and sparkling floors of a ship require a ton of elbow grease to remain clean. I remember very clearly the scene where we see a closeup of Hawkins cleaning astrobarnacles off the ship’s hull, only to pan out and see the entire hull is covered in the little creatures.

Biofouling is a big problem for real-life seafaring vessels as well. When sea creatures big (barnacles) or small (microorganisms) cling to a ship’s hull, they cause drag, reduce fuel efficiency, and potentially even damage the vessel. For the U.S. Navy, biofouling costs them $180–260 million per year in added fuel use and cleaning costs, according to a study in 2011.

Chemical agents are often used to kill fouling organisms, but this method can have negative effects on the ecosystem. On the other hand, nonstick coatings can prevent organisms from attaching in the first place, but current coatings only last for a short duration.

In a recent open-access paper, researchers led by the University of Massachusetts Amherst, with funding from the U.S. Office of Naval Research, reported the development of a new long-lasting coating based on an ultraviolet-emitting glass.

In a UMass Amherst press release, senior author Mariana Lanzarini-Lopes, assistant professor of civil and environmental engineering at UMass Amherst, explains that using ultraviolet radiation to disinfect surfaces and air entered the mainstream during the COVID-19 pandemic when it proved very effective at inactivating the SARS-CoV-2 virus. However, employing this method underwater is more challenging.

“We cannot use traditional light sources to distribute light evenly on the surface,” says lead author Leila Alidokht, postdoctoral research associate in Lopes’s lab, in the press release. Murkiness in the surrounding water can disrupt the ultraviolet waves, and this uneven distribution of the light gives biofilm-forming microorganisms a foothold—thus leaving the whole surface vulnerable when it spreads.

The team’s solution was to embed light-scattering silica nanoparticles into the glass’s surface. When an ultraviolet LED is connected to the glass, the light waves bounce off the nanoparticles and throughout the glass interior, which enables an evenly “glowing” glass surface.

To test the glass’s ability to prevent biofouling, the UMass Amherst researchers partnered with Florida Institute of Technology and the U.S. Naval Research Laboratory to submerge the ultraviolet-emitting glass in the waters of Port Canaveral, Fla., for 20 days. Compared to untreated glass, the modified glass reduced visible biofilm growth by 98%.

In the press release, Alidokht expressed her excitement for the diverse disinfection applications that this glass offers.

“The developed technology can be used for disinfection of transparent surfaces, such as windows of ships, flotation spheres and moored buoys, [and] camera lenses and sensors for oceanographical, agricultural, and water treatment applications,” she says.

The team is now testing long-term applications of the glass and exploring the creation of larger surface areas. They already received a provisional patent for their discovery.

The open-access paper, published in Biofilm, is “UV emitting glass: A promising strategy for biofilm inhibition on transparent surfaces” (DOI: 10.1016/j.bioflm.2024.100186).

Author

Lisa McDonald

CTT Categories

- Environment

- Glass

- Material Innovations