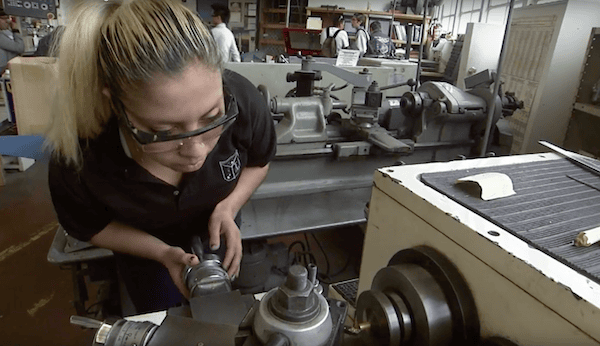

[Image above] Credit: Manufacturing Education; YouTube

Manufacturing has always been an important and necessary component of a country’s economic growth. According to the National Association of Manufacturers (NAM), the manufacturing industry contributed $2.25 trillion to the U.S. economy in 2016. Manufacturing jobs also account for 8.5% of the U.S. workforce.

The NAM also reports that from 2000–2014, research and development in the manufacturing sector has increased 82%, from $126.2 billion to $229.9 billion.

Manufacturing also contributes to the global economy. In that same timeframe, world trade of manufactured goods increased 154%, from $4.8 trillion to $12.2 trillion. Of that $12.2 trillion, the U.S. share was around 34% or $4.1 trillion.

Manufacturing has changed dramatically over the years. Between advances in technology and automation, including robotics, manufacturing output has increased 47% from two decades ago. And as advanced manufacturing continues to evolve, it presents a new set of challenges, such as the impact of technology, the need for increased investment for R&D, energy efficiency requirements, and workforce training.

And the U.S. Department of Energy recognizes these challenges. To that end, it recently announced funding for up to $35 million for two dozen projects “to support early-stage, innovative technologies and solutions in advanced manufacturing” according to a news release on Energy.gov.

Working with the Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office, 24 organizations consisting of private enterprise, national laboratories, nonprofits, and universities will conduct early stage research and development of new technologies and processes to help U.S. manufacturers increase their energy efficiency and stay competitive in the global market.

Among the projects receiving funding are:

- FeNix Magnetics—Working to develop technology for large scale production of rare-earth element-free magnetic materials for clean energy applications;

- Lawrence Livermore National Lab—Optimizing copper catalyst performance by improving energy efficiency to convert CO2 into methane to fuel vehicles and power plants;

- Saint-Gobain—Developing a process to reduce the number of manufacturing steps in the production of fuel cells, batteries, photovoltaics, and capacitors;

- Starfire Industries—Improving adhesive joint performance and corrosion protection in lightweight vehicle construction for harsh environments;

- United Technologies Research Center—Developing high-temperature/high-strength heat exchanger technology from a glass-ceramic composite material for extreme environments; and

- Yale University—Working on a high-efficiency and low-cost process to generate energy from waste heat using pyroelectric materials.

You can view the rest of the list here.

Workforce training is critical for advanced manufacturing industry

The DOE’s funding initiative addresses the first three advanced manufacturing challenges. But what about workforce training?

NAM reports that of the 3.5 million manufacturing jobs that will be needed in the next decade, 57% or 2 million will go unfilled because of the skills gap. And 80% of manufacturers claim they have a moderate or serious shortage of qualified applicants for skilled and highly skilled production positions.

However, it appears that a few organizations are already addressing this issue.

The Chicago Tribune reports that Illinois’ manufacturing sector has been declining since 2000, and employers are finding it difficult to fill positions left vacant from retiring baby boomers. So several Chicago-area manufacturers have organized to create the Golden Corridor Advanced Manufacturing Partnership (GCAMP) with a goal of promoting manufacturing careers.

In a similar initiative, the nonprofit SME Education Foundation launched its Partnership Response in Manufacturing Education (PRIME) program in 2011. The program provides students with hands-on learning in a manufacturing setting. Its goal is to address the skills gap by expanding its network of industry partners, according to this video. One outreach effort resulted in a partnership with NASA’s HUNCH program.

Most recently, a Lexington, Mass., high school used a $995,000 grant from the state of Massachusetts to open the Advanced Manufacturing Lab to train adults and high school students for jobs in advanced manufacturing.

While the federal government addresses the critical needs of the manufacturing industry, businesses can do their share to inspire students at the local level. By donating a Materials Science Classroom Kit to science teachers in your local school district, you are helping a new generation of students get excited about pursuing careers in science.

Visit this link to learn more about the DOE’s funding initiative to solve manufacturing challenges.

Visit this link to learn how you can make a difference in supporting STEM programs in your area. Watch an example of a lesson from the Materials Science Classroom Kit in the video below.

Credit: Ceramic and Glass Industry Foundation; YouTube

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Education

- Manufacturing

- Market Insights