[Image above] Credit: European Patent Office

If you’ve ever had to drive on a pothole-filled road, you probably understand the frustrations structural and civil engineers go through when dealing with concrete repairs after a hard winter.

In the U.S., repair costs for highways and bridges can run into the trillions. And that doesn’t include repairs to our vehicles when we drive over said potholes.

Perhaps we may soon see the end of all potholes, cracks, and crevices in our concrete roads and structures.

Two Dutch microbiologists, inspired by nature’s way of healing bones and tissue in the human body, have invented a process for concrete to heal itself when it develops cracks and crevices.

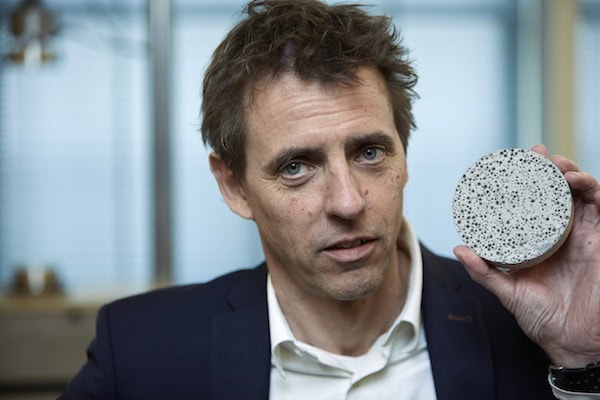

Hendrik Jonkers and Erik Schlangen of Delft University of Technology encapsulated Bacillus pseudofirmus and Bacillus cohnii bacteria, along with a food source (calcium lactate), in biodegradable plastic and mixed the capsules into wet concrete. When water seeps into cracked or damaged concrete, it “awakens” or activates the bacteria to multiply—combining with the calcium to form limestone, which ultimately closes up the cracks.

“So, what we do is we replace the stones for hollow spheres, which we fill with food and bacteria, and add that to the concrete mixture,” Jonkers explains in a video on Mashable.

Concrete’s history

Concrete is one of the strongest building materials and probably one of the oldest. The forerunner to today’s concrete was more of a crude mixture made by crushing and burning limestone or gypsum. Back in the “olden” days (we’re talking B.C. here!), Middle Eastern builders of that era discovered a way to coat the outside of their homes and castles (made out of clay) with a coating of burned limestone, which formed a hard surface when it reacted with gases in the air.

Romans eventually adopted concrete as a building material, and today their structures still stand as a testament to concrete’s strength.

But despite its superiority as a construction and building material, concrete still has its weaknesses.

Self-repairing concrete

Researcher Carolyn Dry first experimented with self-healing concrete back in the 1990s. Instead of the bacteria that Jonkers and Schlangen used, Dry used methyl methacrylate glue encapsulated in glass, according to an article in Chemical & Engineering News. Unfortunately, the glues she used were not runny enough to fill the cracks, and the glass capsules tended to break during mixing of the cement.

Comparing the process to human skin’s self-healing mechanism, Victor Li, civil and environmental engineering professor at the University of Michigan, who also experimented with self-healing concrete, explains in the article that “the trick to making self-repairing concrete is to heal microscopic fissures before they become large cracks.”

Jonkers and Schlangen continue to further test their process by creating cracks in concrete on a lifeguard station they built. They are also testing other lower-cost food sources to replace calcium lactate, and may eventually have a product on the market soon. Stay tuned.

Their paper is “Self-healing of cracked concrete: A bacterial approach.”

Watch the video below to learn more about self-healing concrete.

Credit: Mashable News; YouTube

Author

Faye Oney

CTT Categories

- Biomaterials & Medical

- Cement

- Construction

- Environment

- Material Innovations

Spotlight Categories

- Member Highlights