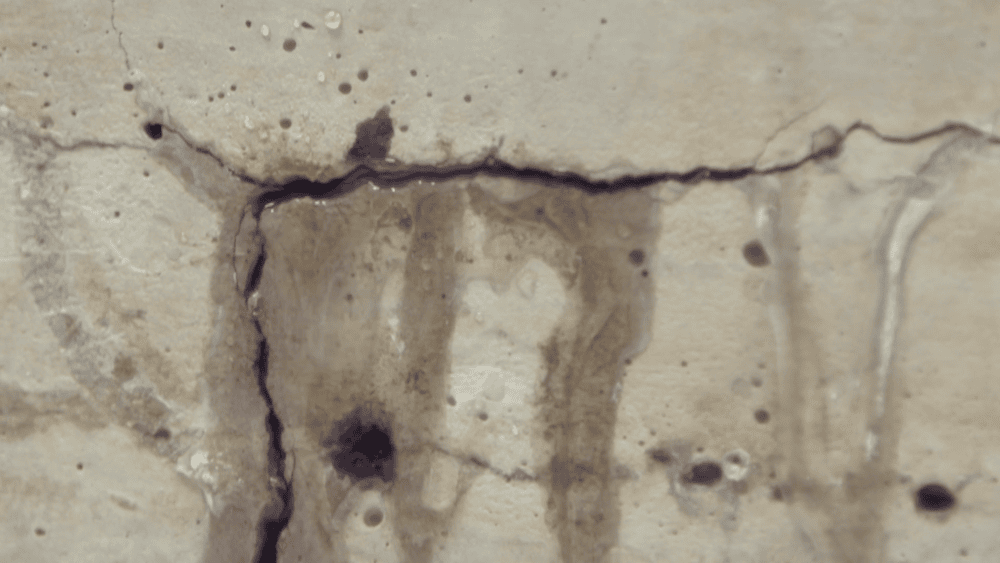

[Image above] With self-healing concrete, the need for construction repairs would decrease, ideally leading to less time spent in construction-caused traffic. Credit: BBC Richard Westcott, YouTube

Snowstorms, accidents, never-ending one-way streets—all of these obstacles cause headaches for a commuter. But these inconveniences are nothing compared to the most dreaded delay of all: construction season.

The average commuter wastes 42 hours stuck in traffic each year, with 10 percent of that lost time attributed to construction. While some of that construction takes place to improve infrastructure and reduce likelihood of bottlenecks—which account for 40 percent of traffic congestion—construction also takes place to fix regular daily-use wear and tear.

But what if we did not have to fix roads, sidewalks, and buildings when they got old and cracked? What if infrastructure healed itself?

That reality may soon arrive, thanks to self-healing concrete.

A self-healing material is capable of repairing itself back to its original state. Many old concrete structures exhibit this self-healing phenomenon due to unhydrated cement in the concrete. When unhydrated cement is exposed to water and carbon dioxide, calcium carbonate forms and seals the cracks. However, newer concrete structures are less likely to exhibit self-healing because they contain less unhydrated cement.

Researchers began experimenting with self-healing concrete in the 1990s, looking for ways more reliable than unhydrated cement to encourage self-healing. Many self-healing strategies use bacteria; when water seeps into a crack, it activates the bacteria to multiply and combine with calcium to form limestone. Some creative researchers tried fungal spores; when water and oxygen reach the fungal spores, they germinate, grow, and precipitate calcium carbonate.

However, not all currently-studied techniques to encourage self-healing require living organisms. Today’s video highlights research investigating one of these non-living techniques.

Since 2014, the Cambridge team uses a Dolomite Microfluidics system to create their double emulsion microcapsules. The microcapsules contain ‘healing’ agents that stabilize concrete when a crack breaks the microcapsules. Credit: BBC Richard Westcott, YouTube

Abir Al-Tabbaa, professor of geotechnical engineering at the University of Cambridge, leads a Cambridge research team working on the EPSRC-funded Resilient Materials 4 Life (RM4L). RM4L is a follow-up program to the three-year Materials for Life (M4L) project, which investigated development of self-healing cementitious construction materials. The goal of RM4L is to transform construction materials by 2022 using a biomimetic approach, i.e., using synthetic methods to mimic natural processes.

The Cambridge team works with three other United Kingdom universities and industry partners, and each group focuses on a different self-healing technique. At Cambridge, the focus is development of microcapsules containing mineral healing agents.

“We are hoping to overcome [concrete cracking] by adding microcapsules filled with ‘healing’ agents—such as minerals, epoxy or polyurethane—to the concrete before it is used,” says Livia Ribeiro de Souza, a postdoctoral researcher in the Cambridge group, in a news release. “The idea is that, as cracks begin to form, they rupture the microcapsules, releasing their payload and stabilizing the material.”

In today’s video, several members of the Cambridge research team talk with BBC about their research and show what the microcapsules look like in action.

No one at this point knows which self-healing technique will work best in construction. Based on results from the first site trial during project M4L, though, “different self-healing techniques will be best suited to different applications and … it will therefore be necessary to clearly identify the damage mechanism that is being targeted to tailor the technique that is adopted.”

Hopefully for us, the best technique for roads will be identified soon—I for one can’t wait to see road construction decrease!

Credit: BBC Richard Westcott, YouTube

Author

Lisa McDonald

CTT Categories

- Cement

- Construction

Spotlight Categories

- Member Highlights