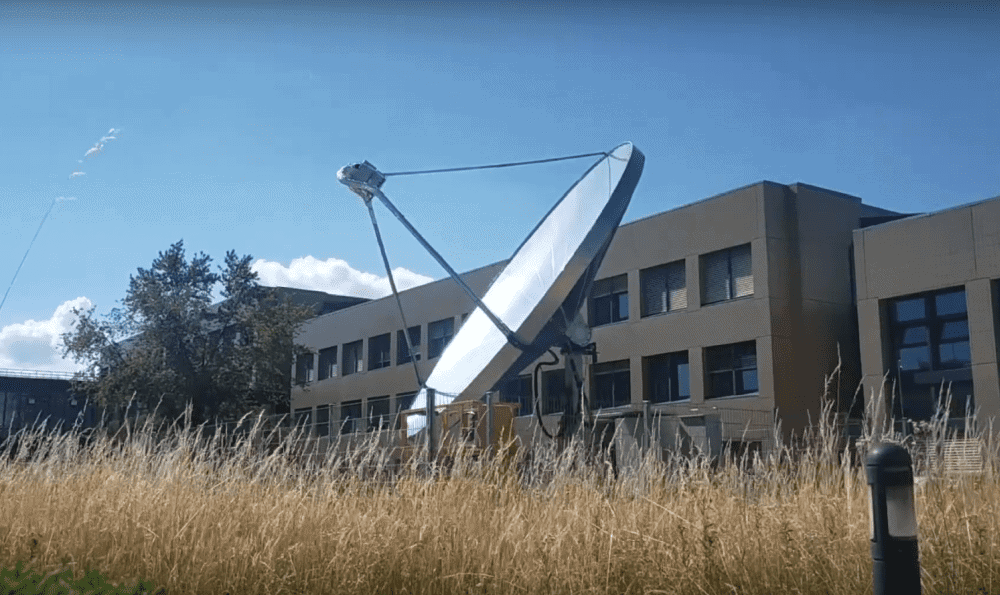

[Image above] SoHHytec’s concentrated solar power system produces about half a kilogram of hydrogen in 8 hours, which amounts to a little over 2 kilowatts of equivalent output power. Credit: Gebert Rüf Stiftung, YouTube

The exploration of hydrogen as an alternative industrial fuel source is heating up.

Compared to conventional hydrocarbon fuels, hydrogen only creates water when combusted. That means it can play a significant role in reducing carbon dioxide emissions.

Yet as states vie for federal funding to set up hydrogen infrastructure, and companies start running hydrogen fuel mix tests, there are challenges that must be overcome for hydrogen to become a viable large-scale fuel source.

The development of refractory ceramics that can handle the higher heat release rate of hydrogen firing is one barrier to commercialization. Researchers are making great strides toward overcoming this obstacle. But production of hydrogen fuel is another challenge that presents a major hurdle.

Currently, most hydrogen is produced through steam reforming of natural gas. This “grey” hydrogen process emits about 9–11 kg of CO2 per kg of hydrogen production.

“Green” hydrogen can be produced through water electrolysis. This process emits no CO2 if renewable energy sources, such as wind and solar power, provide the electricity.

However, producing hydrogen through water electrolysis is not yet financially viable due to challenges with scaling up the process. As such, in 2021, green hydrogen accounted for less than 0.1% of worldwide hydrogen production, according to a BCC Research report.

Solar hydrogen company SoHHytec is working to overcome the scale-up challenge.

SoHHytec is a Swiss-based startup that grew out of the Swiss Federal Institute of Technology Lausanne (EPFL). Their solution, which is based on almost a decade of research and development, uses concentrated solar power to improve the efficiency of green hydrogen production.

In their system, which is illustrated below, a 7-meter-wide parabolic solar dish covered with reflective mirrors concentrates solar radiation onto tandem multijunction III–V semiconductor solar cells. The electricity produced by the solar-cell module drives the water electrolysis process, which takes place through a polymer electrolyte membrane electrolyzer.

Not all of the concentrated solar energy is converted to electricity. Some of it is converted into waste heat, which is extracted using a heat exchanger. This heat can then be used for space heating or hot water in buildings.

a) Technical illustration of the overall site showing key components, such as the solar parabolic concentrator dish, reactor, and ancillary hardware and cabinets. b) Close-up of the integrated reactor showing the assembly of the shield, homogenizer, photovoltaic module, and enclosure. Credit: Holmes-Gentle et al., Nature Energy (CC BY 4.0)

A pilot plant based on this system produced about half a kilogram of hydrogen in 8 hours, which amounts to a little over 2 kilowatts of equivalent output power. This much energy would allow a car to be driven for about 100 miles (160 kilometers).

This result is significant because it is the first time “We have cracked the 1-kW ceiling for the production of solar hydrogen,” says Sophia Haussener, EPFL professor of renewable energy science and engineering, in an IEEE Spectrum article.

SoHHytec is now building a system with a larger, 9-meter-wide parabolic solar dish. The first demonstration project for the larger system, which is slated to be operational by the end of 2023, will be for a metalworking company that will use the hydrogen and heat for metal processing. Eventually, the SoHHytec researchers imagine that customers will be able to tie together multiple dishes, which will allow the system to be made as big or small as needed.

You can learn more about SoHHytec’s system, which they call Arb, in the video below.

Author

Lisa McDonald

CTT Categories

- Energy

- Material Innovations