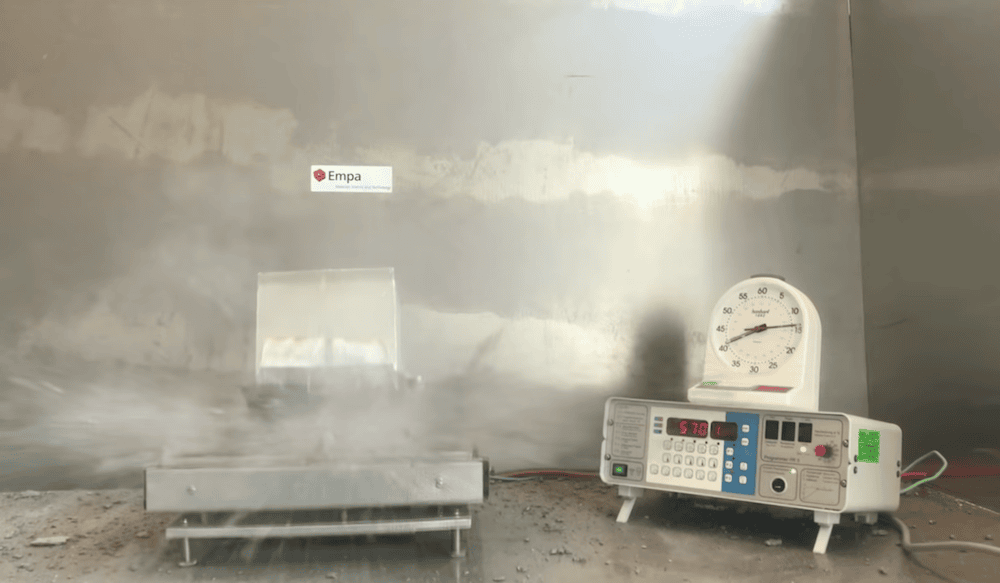

[Image above] Researchers from Empa, the University of Grenoble, and the Institut Laue-Langevin performed neutron tomography to observe the internal mechanisms that cause concrete to explode under high heat. Credit: EmpaChannel, YouTube

When I think of concrete, I think of a durable, long-lasting material that can withstand all sorts of weather conditions and last for hundreds (and thousands) of years.

What do I not think of? Explosions.

Credit: EmpaChannel, YouTube

The explosion seen above is an extreme example of spalling. Spalling, which has been studied since at least the mid-1800s, is a physical process in which surface layers of masonry materials (like concrete) crumble into small pebble-like pieces in response to high temperatures and/or mechanical pressures.

Homeowners commonly deal with spalling in their driveways and sidewalks during winter, when cold temperatures cause water in concrete to freeze, expand, and induce cracks. In contrast to this slow spalling process, explosive spalling occurs when concrete is exposed to high temperatures, and water in the concrete vaporizes quicker than it can escape. This situation results in a rising vapor pressure that ultimately causes the concrete to explode.

Explosive spalling is of special concern to tunnel engineers. If a fire breaks out in a tunnel, heat has limited escape routes and can increase temperatures to over 1,000°C (1,832°F) in a short time, causing concrete to explode like popcorn. The past decade has seen some emerging best practices for tunnel design to mitigate extreme heat buildup, but exact mechanisms behind spalling—the internal processes—are still not completely understood.

A group of Swiss researchers from Empa, the University of Grenoble, and the Institut Laue-Langevin (ILL) hoped to fill some of this knowledge gap using the high-flux reactor at ILL.

According to the ILL website, the ILL high-flux reactor produces “the most intense continuous neutron flux in the world.” This flux allowed the researchers to perform a neutron tomography experiment in which they captured one 3D scan per minute, which is sufficient to follow the fast water vaporization process.

An Empa press release explains why high-performance concrete in particular is susceptible to explosive spalling. “High-performance concrete generally has very low porosity and very fine pores. These properties are of great advantage as they provide high strength and exceptional durability … However, the low permeability of high-performance concrete turns out to be a disadvantage in the case of a fire with very high temperatures because water vapor cannot escape and extremely high vapor pressures can build up.”

In today’s video, you can see the researchers create and insulate concrete cubes to keep water vapor from escaping, ensuring pressure will build and lead to a satisfying *bang*.

While watching explosions in these controlled settings is entertaining, hopefully their research can help keep such explosions from happening in any new tunnels we drive through.

The paper, published in Cement and Concrete Research, is “Analysis of moisture migration in concrete at high temperature through in-situ neutron tomography” (DOI: 10.1016/j.cemconres.2018.06.010).

Credit: EmpaChannel, YouTube

Author

Lisa McDonald

CTT Categories

- Cement

- Construction

Spotlight Categories

- Member Highlights