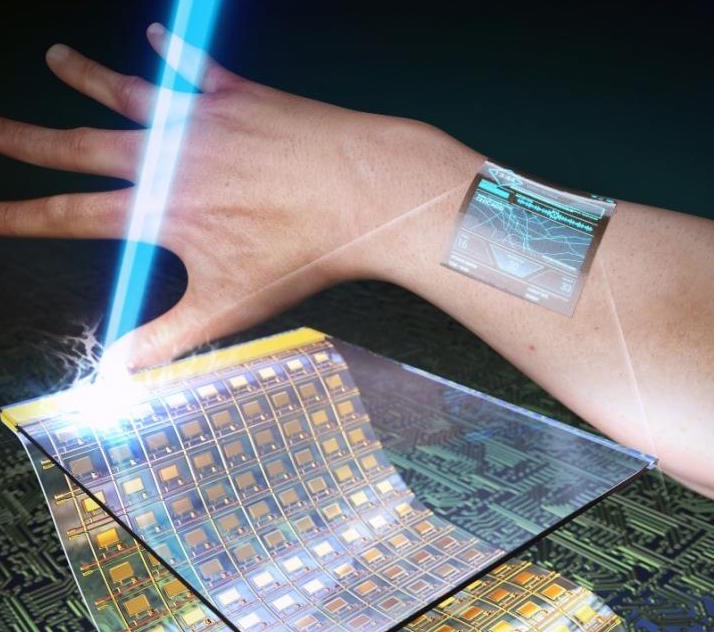

[Image above] Ultrathin, flexible, and transparent oxide thin-film transistors produced via KAIST’s new ILLO process. Credit: KAIST

Improvements in wearable technology continue to trend this year. And the goal seems to be twofold: create wearables with such mass-market aesthetic appeal that consumers will actually want to wear these devices, but also make them thinner with more flexibility and enhanced efficiency.

The 2016 Consumer Electronics Show in Las Vegas at the beginning of the year showcased the latest wearable technologies with features like low energy Bluetooth, cloud computing, 3-D printing, and flexible membranes that will transform this market.

Good thing, too, because in the age of the Internet of Things we expect our consumer electronic tech to do increasingly more for us. We want our smartphones, laptops, and tablets thinner, more durable, and flexible with sharp mega-pixel displays. We expect our cameras to be smaller and more versatile without sacrificing image quality. And we wanted it yesterday.

So researchers are turning to advanced materials to help speed up the development of next-generation wearable tech.

In June, we reported on research from the Korea Advanced Institute of Science and Technology (KAIST), where scientists say they’ve created the ideal electrode structure composed of graphene and layers of titanium dioxide and conducting polymers, resulting in highly flexible and efficient organic light-emitting diodes (OLEDs).

Flexible OLEDs, when built on thin substrates—like plastic, glass, or foil—can be used to create next-gen electronic displays that can be rolled or bent while remaining fully operational, the researchers explained.

Last week, KAIST made waves in innovative electronics again. This time, researchers say they’ve developed ultrathin, transparent oxide thin-film transistors for wearable displays.

When it comes to creating flexible transparent displays, researchers have faced real challenges—including (but not limited to) poor transparency and low electrical performance, the release explains. Past attempts to solve these issues relied on inorganic-based electronics—like using the aforementioned plastic substrates during fabrication. But the thermal instabilities of such substrates mean they can’t quite stand up to the high-temperature fabrication process required to create high-performance electronic devices.

To solve this problem, the team, led by Keon Jae Lee and Sang-Hee Ko Park at KAIST’s Department of Materials Science and Engineering, fabricated “ultrathin and transparent oxide thin-film transistors (TFT) for an active-matrix backplane of a flexible display by using the inorganic-based laser lift-off (ILLO) method,” according to a KAIST press release.

Ultrathin, flexible, and transparent oxide thin-film transistors attached to a jumper sleeve and human skin. Credit: KAIST

The ILLO process to create these high-performance oxide transistors involves several steps, the release explains.

First, the team fabricated the TFT array on top of a sacrificial laser-reactive substrate. After laser irradiation from the backside of the substrate, only the oxide TFT arrays were separated from the sacrificial substrate as a result of reaction between laser and laser-reactive layer, and then subsequently transferred onto ultrathin plastics (4-μm thickness). Finally, the transferred ultrathin-oxide driving circuit for the flexible display was attached to the surface of human skin to demonstrate the possibility of the wearable application. The attached oxide TFTs showed high optical transparency of 83% and mobility of 40 cm2 V-1 s-1 even under several cycles of severe bending tests.

“By using our ILLO process, the technological barriers for high performance transparent flexible displays have been overcome at a relatively low cost by removing expensive polyimide substrates,” Lee explains. “Moreover, the high-quality oxide semiconductor can be easily transferred onto skin-like or any flexible substrate for wearable application.”

The research, published in Advanced Functional Materials, is “Skin-like oxide thin-film transistors for transparent displays” (DOI: 10.1002/adfm.201601296).

Author

Stephanie Liverani

CTT Categories

- Electronics

- Manufacturing

- Material Innovations

- Nanomaterials