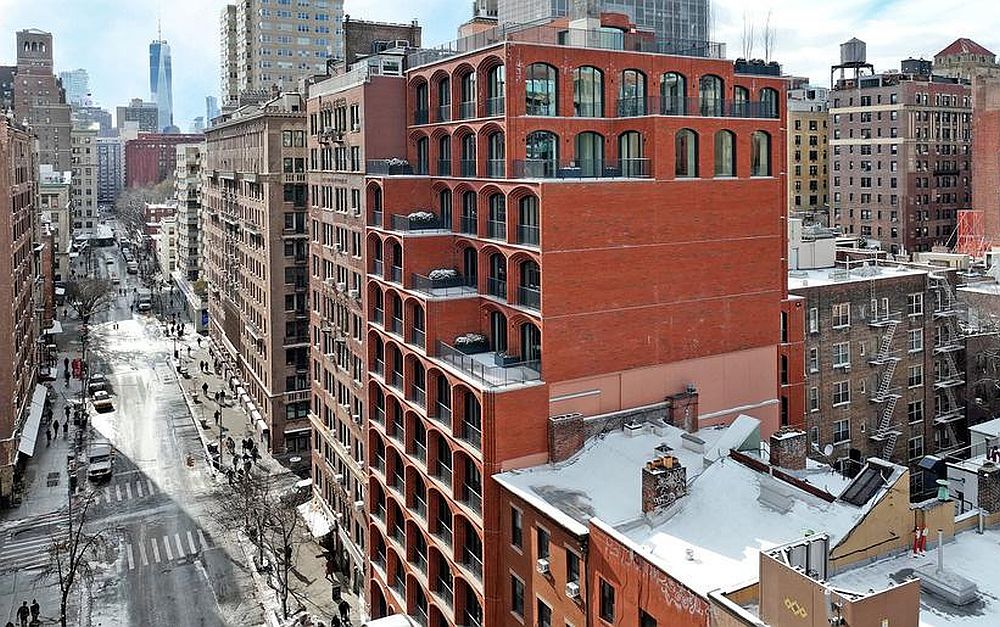

Credit: Quinn Dombroski; Flickr CC BY-SA 2.0

Concrete is one impressive material.

In addition to a long, rich history, the ancient building material is much more complex than its unassuming dull gray surface might suggest.

I can understand why some people might consider concrete to be a low-tech or even no-tech material, but that’s not necessarily true. There’s actually some really interesting nanoscience going on within the cement that glues concrete together that allow concrete structures to endure—sometimes even for thousands of years.

With recent advances in computational modeling and molecular analysis techniques, scientists have been teasing apart these mechanisms in an effort to better understand concrete’s strength. Ultimately, that knowledge can help engineer improvements that boost the strength and reduce the high environmental impact of concrete.

Because despite its material strength, that is concrete’s weakness—its huge carbon footprint.

The fact that current concrete manufacturing accounts for 8%–9% of anthropogenic CO2 emissions and 2%–3% of global primary energy really demands improvements in this ubiquitous material.

Here on Ceramic Tech Today, we’ve reported on countless R&D endeavors to make concrete more green.

But can these incremental advances—which, unfortunately, often never more beyond the research lab—significantly shift the concrete industry?

Maybe.

There are some recent advances in cleaning up concrete’s act that are gaining commercial and industrial traction. One prime example is Solidia Technologies’ manufacturing process—which not only reduces carbon dioxide emissions, but also enables a commercially feasible concrete product that actually absorbs CO2.

The world is going to need the entire concrete industry to get on board with such innovative solutions, however, to really put the brakes on the concrete industry’s CO2 problem.

Still, others think that concrete’s problems are more deeply rooted in the material itself—so they are instead pushing for entirely different materials to replace concrete’s position as the go-to building material.

And with some new innovations, that just might be possible.

A study published online this week in Nature details a process for making wood into a high-performance structural building material.

The technique consists of a series of chemical processing and hot-pressing steps that ultimately fix wood’s structural weakness—its natural porosity.

By first chemically processing wood to increase its porosity and then compressing it to smush out all the spaces, the process causes nanofibers within the wood to interlock together, creating a strengthened organic material, according to the scientists.

Densifying wood in this way increases its stiffness by a factor of 11 and its density by a factor of 3, according to a Nature news story.

Beyond this new study, there also are other processing options to increase the strength of wood as a building material. One such possibility is cross-laminated timber, which gets added strength from wood layers that are are oriented perpendicularly to one another.

Wood is a particularly attractive option as a building material because, for starters, wood is a renewable resource. Allowing nature to manufacture the materials drastically reduces the emissions created during the manmade manufacture of other building materials, such as concrete. Plus, growing trees as a building material supply has the added benefit of absorbing CO2 as the plants grow, too.

But wood isn’t actually strong enough to build tall skyscrapers and entire cities…is it?

Check out the video below from The Economist to see how experts would disagree—and how they’re already making it happen.

Credit: The Economist; YouTube

The Nature paper is “Processing bulk natural wood into a high-performance structural material” (DOI: 10.1038/nature25476).

What do you think—is it possible that wood could someday replace concrete as our go-to building material? Why?

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

April Gocha

CTT Categories

- Cement

- Construction

- Energy

- Environment

- Material Innovations

- Weekly Column: “Other materials”