Posts by Lisa McDonald

Ceramic and glass business news of the week for October 2, 2023

U.K. and Germany sign hydrogen energy collaboration agreement, National Academies decadal survey seeks tenfold boost for spaceborne research budget, and more ceramic and glass business news of the week for October 2, 2023.

Read MoreHarnessing nature for nano design—glass-coated DNA scaffolds demonstrate potential as lightweight and high-strength materials

In recent decades, researchers have explored using deoxyribonucleic acid (DNA) as a scaffold for programmable nanostructures. Now, researchers at Columbia University, the University of Connecticut, and Brookhaven National Laboratory collaborated to show that glass-coated DNA scaffolds have potential as lightweight and high-strength materials.

Read MoreVideo: Silica, a common food additive, may be chemically reactive

The increasing use of nanoparticles across all sectors has led to some concerns within the food industry, as nanoparticles do not necessarily behave the same way as their larger counterparts. A new study by Stanford University researchers showed that mesoporous silica, a common food additive, can react with key biomolecules, which could lead to increased oxidative stress in the body.

Read MoreOther materials stories that may be of interest for September 27, 2023

MXene-enhanced hydrogel sensors, next-generation solar panels, and other materials stories that may be of interest for September 27, 2023.

Read MoreBuilding with nature: Fungi show promise as green construction material

More and more companies and organizations are considering the potential of mycelium, the root-like structure of most fungi, as a green construction material. Today’s CTT spotlights several recent innovations in this area.

Read MoreCeramic and glass business news of the week for September 25, 2023

Nevada could be home to world’s biggest lithium deposit, Honeywell Aerospace and NREL partner to scale hydrogen fuel storage solution for drones, and more ceramic and glass business news of the week for September 25, 2023.

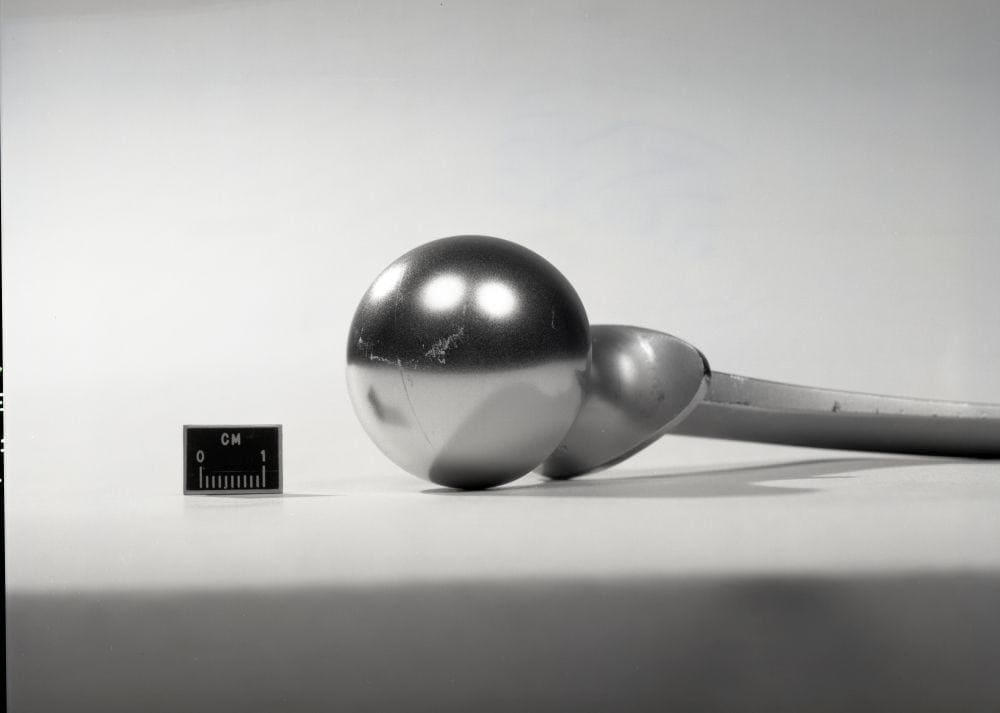

Read MoreIntegrating orthopedic implants—several strategies improve adhesion strength of bioactive glass coatings

Bioactive glass offers numerous benefits as a coating material for metallic implants, but achieving strong adhesion between the glass and implant is a challenge. University of Barcelona researchers explored several strategies for improving the adhesion strength of bioactive glass coatings deposited using atmospheric plasma spraying.

Read MoreVideo: Years of slashed infrastructure spending culminates in crumbling concrete crisis in the UK

Years of slashed infrastructure spending by the U.K.’s Conservative-led government has culminated in a crumbling concrete crisis as buildings constructed out of reinforced autoclaved aerated concrete begin to fail after being pushed beyond their intended lifespan.

Read MoreOther materials stories that may be of interest for September 20, 2023

Mass production of MXenes, making hydrogen from plastic waste, and other materials stories that may be of interest for September 20, 2023.

Read MoreDeveloping cement-free refractories: Geopolymer binders show potential in high-temperature alumina castables

Geopolymers are emerging as a promising alternative to cement binders in refractories. In a recent study, researchers in Brazil identified a new geopolymer composition that could serve as a binder in high-temperature alumina castables.

Read More