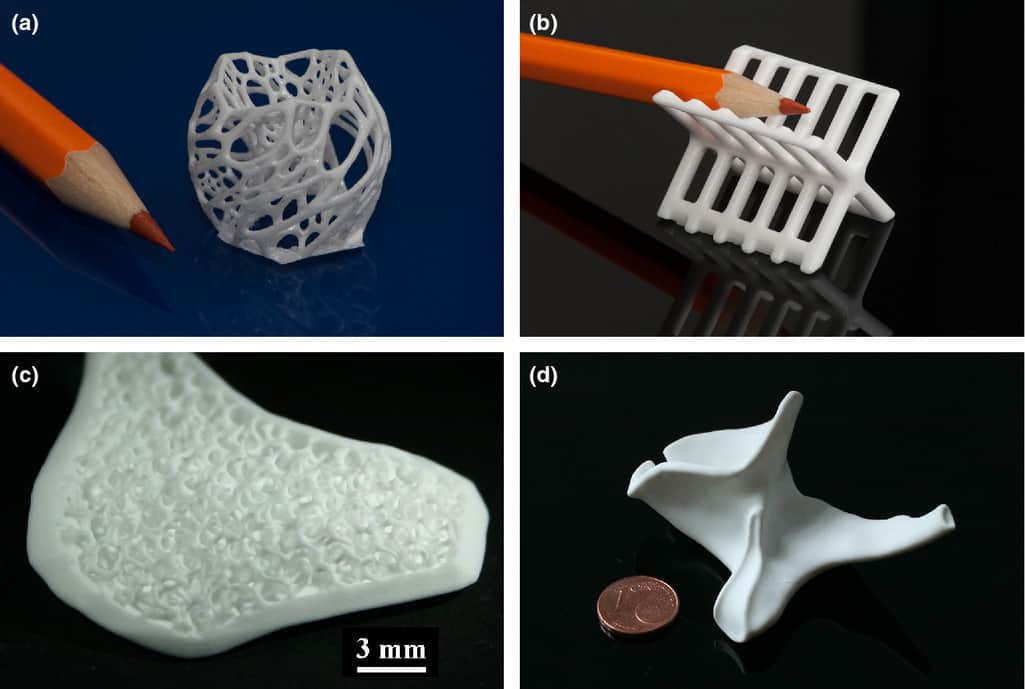

[Image above] Sintered alumina parts fabricated using the lithography-based ceramic manufacturing technique. Credit: Schwentenwein and Homa, International Journal of Applied Ceramic Technology

In the world of materials manufacturing, there are few recent developments more universally exciting than additive manufacturing.

Also known as 3D printing, additive manufacturing is the process of building up three-dimensional parts layer-by-layer. It is a truly universal process, as the technologies and techniques are being simultaneously developed, employed, and refined for metals, polymers, and ceramics. Additive manufacturing is even being touted for onsite manufacturing of concrete buildings!

The unique advantage of additive manufacturing is its ability to form complex shapes, particularly those with complex internal structures, that cannot otherwise be produced. Additive manufacturing has been a game changer for rapid prototyping and small batch manufacturing because parts can be made without molds, dies, or other expensive tools—and with minimal waste!

Two basic technologies dominate this field: deposition of fluid-based materials, and impinging light on materials in a reservoir to melt them or initiate reactions. Metal part manufacturers typically employ laser melting of powdered metals. Meanwhile, for polymer manufacturers, perhaps the most familiar technique—and sufficiently inexpensive for home use—is fused filament printing, in which a polymeric “string” is fed to a hot nozzle. The molten polymer rapidly solidifies after deposition to form the desired shape.

Developers and manufacturers of ceramics and glass use additive manufacturing methods mainly to fabricate shapes in the green state, which are then fired to form the dense structures. The “raw” materials for ceramics additive manufacturing can be pastes or slurries (e.g., for direct ink writing, photoreaction of polymeric binder materials, or light-enhanced drying of binders), pre-ceramic polymer filaments, ceramic powders embedded in polymeric carrier filaments, and others.

Scientists and engineers are exploring additive manufacturing for all stages of research, development, and deployment. New materials, powder characteristics, slurry formulations, and firing schedules are required for successful deployment. While the benefits for prototyping and small manufacturing are clear, the technique is rapidly becoming cost effective for larger scale ceramics manufacturing, particularly with advances in near-net-shape production.

International Journal of Applied Ceramic Technology has been and remains at the forefront of publishing research on the development and application of additive manufacturing. The universality of this topic within ceramics application areas led us to choose it to kick off the “ACT @ 20” celebration.

Our editors chose five excellent articles from leading researchers that explore the ranges of materials, applications, and types of additive manufacturing for ceramics production. The articles for this month’s ACT @ 20 celebration are below. They are free-to-read for the remainder of January. And, as always, ACerS members enjoy free unlimited access to all articles published in our journals.

Articles for Additive manufacturing

Author

Jonathon Foreman

Spotlight Categories

- Journal and Bulletin Updates

Related Posts

Volunteer spotlight: Hyunjun Kim

December 18, 2025

ACerS GOMD History – A Look Back in Time

December 10, 2025