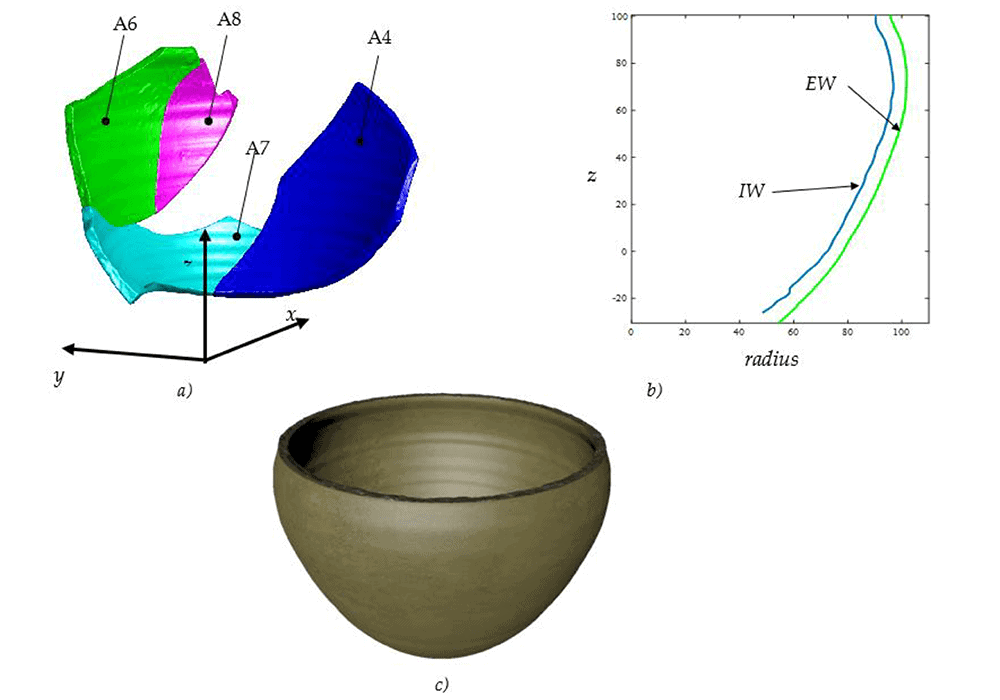

[Image above] (a) The simulated assembly of four archaeological fragments identified by an algorithm. (b) The longitudinal profile and (c) rendering of the 3D virtual reconstruction of an archaeological vessel. Credit: Di Angelo et al., Sensors (CC BY 4.0)

With everything going on in the world right now, it can be difficult to feel hopeful for the future. But even in the hardest times, humans’ resiliency can shine through, as students demonstrated in their annual section in the ACerS Bulletin June/July 2022 issue.

Students shared the many things that inspire them to hope, from increased awareness and support for mental health to technologies for a cleaner environment to the benefits of collaboration.

History can also serve as inspiration, as student Celia Chari demonstrated in her article on historic glazes from 1700s Germany (pg. 39). Despite high-pressure work environments, alchemists at the Meissen manufactory still flourished in their production of porcelain and other ceramic objects, which are renowned today.

In addition to the social aspect of glaze development, Chari highlights how the scientific aspect inspires as well. Thanks to today’s advanced imaging and analytical techniques, Chari and her colleagues revealed the nanoscale engineering that gave a historic glaze its iridescence.

“Yet as I get further into my research, it is sobering to realize that some research questions cannot be answered even with our advanced techniques. That does not mean, however, they cannot be answered in the future when the right analytical equipment and literature is available to aid in investigation,” Chari writes.

Fortunately for Chari, researchers in cultural heritage and archaeology are incorporating more computer-based methods to aid in identification, classification, and reconstruction of ancient artifacts. As the field continues to embrace these methods, advancements are sure to follow that will allow us to answer even more questions about the past.

In pursuit of these advancements, researchers at the University of L’Aquila in Italy published a review paper that outlines the strengths and weaknesses of current state-of-the-art computer-based methods for classification and reconstruction of archaeological pottery.

For this review, they considered only the pottery analysis, classification, and reconstruction methods starting from a 3D discrete model. The resulting 125 selected papers on this topic were divided into six groups:

- 3D digitalization and virtual prototyping,

- Fragment features processing,

- Geometric model processing of whole-shape pottery,

- 3D vessel reconstruction from its fragments,

- Classification, and

- 3D information systems for archaeological pottery visualization and documentation.

In addition to listing the pros and cons of various techniques within each group, the researchers provide recommendations for future studies.

3D digitalization and virtual prototyping

The 3D digital model reconstruction of a ceramic requires four distinct steps: points cloud acquisition, noise reduction, registration and decimation, and tessellation.

Regarding acquisition, archaeologists have used 3D scanning technologies in cultural heritage studies since the 1990s. To date, the most used technologies for pottery preservation are image-based photogrammetric modeling, modeling with range imaging cameras, structured light scanning, and triangulation-based laser scanning. All these technologies are optically based, meaning they are limited to acquiring only visible surfaces; some features, such as small undercuts that are not accessible by the sensor, cannot be acquired.

Regarding noise reduction, processing of raw data generated by 3D scanners typically consists of two phases: outliers’ detection/erasing and points cloud denoising. Outlier detection remains a challenge because points are often sparse with nonuniform point density and geometrical discontinuities. Similarly, denoising is a nontrivial procedure because it necessitates a shift in the spatial configuration of the points, which can change the object’s original shape if not done carefully.

The registration step of 3D digital model reconstruction refers to the process of aligning points clouds resulting from different scans of the object taken at various angles. This process may insert additional errors not present in individual acquisitions. Fortunately, some global registration methods proposed in the literature can help overcome this limitation by distributing errors among the registered views.

Tessellation, the final step of 3D digital model reconstruction, interpolates points clouds by triangular planar facets to obtain an oriented surface. The most important published algorithms used for tessellation are grouped into three major categories:

- Implicit methods, in which tessellation is performed on the surface, approximating all or a part of the points cloud.

- Delaunay-based methods, which generate surfaces starting from a volume tetrahedralization of the sample points by 3D Delaunay triangulation.

- Mesh–growing methods, in which tessellation starts from one or more seed triangles and grows by adding triangles that result from the connection of nodes at edges.

Overall, the acquisition systems and subsequent processing steps under optimal conditions allow researchers to obtain points clouds with 0.2-mm density and a negligible noise level. However, the time-consuming scanning phase (~30 min per scan) is a major limitation for all these methods.

“Automated methods for sherds processing will become increasingly widespread if 3D geometric scanners that can efficiently, automatically, and quickly acquire the shape and texture of artefacts are developed,” the researchers state.

Fragment features processing

Geometric model processing methods published in the literature address four different issues: axis identification, profile evaluation, feature segmentation and recognition, and dimensional features evaluation.

The axis is a nonphysical geometric entity that is not directly measurable and has to be derived by analyzing the surface. The axis estimation is a preliminary stage for each quantitative analysis of archaeological ceramics, so its evaluation must be very accurate. Published automatic methods for deriving the axis can be grouped based on the exploited property of axially symmetric surfaces.

The profile is the cross-section of pottery in the direction of the rotational axis symmetry. The profile definition is the first step in documentation, classification, or reconstruction of archaeological pottery. Typically, the computer-aided and automatic methods used for profile definition are refined using an approximating curve.

For feature segmentation and recognition, researchers aim to develop automatic methods that recognize the same features as those used when manually categorizing ceramics. Development of such methods is complicated by the fact that characteristic elements of pottery are not associable to analytical surfaces, and the 3D discrete models come from generally damaged and worn pieces, so geometric properties are lost.

Dimensional features support pottery classification and reconstruction of the complete vessel from fragments. The published methods for dimensional features evaluation can be classified into two categories, depending on whether they are based on preliminary feature segmentation.

To advance use of computer-based methods in this area, “Efforts should be made to define replicable and codifiable observational units to base ceramics analysis, classification, and reconstruction,” the researchers state.

Geometric model processing of whole-shape pottery

When the whole geometric shape is available, evaluations are more accurate and robust because the information is complete. The methods and evaluations presented above can be used for modeling whole-shape pottery; researchers also developed methods specifically for complete vessels.

One specific evaluation of whole-shape pottery that greatly interests archaeologists is estimating the pottery’s capacity. Pottery plays a fundamental role in reconstructing ancient trade routes and economic systems, so quantifying contents of the vessels through volume and weight evaluation of the material it was supposed to contain is helpful.

3D vessel reconstruction from its fragments

In general, whole-shape pottery is a rare find; archaeological ceramics are often found as fragments. Trying to assemble the complete shape from fragments is complicated, though, by physical degradation of the fragments, missing fragments, and lack of knowledge on how many pots should be reconstructed when fragments come from a collection. In the face of these challenges, archaeologists typically approach pottery reconstruction by clustering fragment candidates for matching and assembly of fragments.

Clustering of fragments is typically performed using some similarity criteria, including overall fragment size, thickness measured along the fractured part of the fragment, material texture, shape continuity, color, decorations, and overall shape. Once fragment candidates for matching are clustered, archaeologists proceed with assembly, which is a time-consuming activity that can introduce degradation.

Recently developed computer-aided, automatic, or semi-automatic methodologies for aiding pottery reconstruction from fragments are based on shape matching, such as one single descriptor for the geometric 3D, correspondences among the objects elements, and combining texture and geometry information. Some new studies expanded these methods to account for additional similarity criteria (given in the paragraph above).

“Regarding the clustering, future efforts should address similarity among fragments when the original model is missing or correctly analyze the small fragments, which are most finds. Concerning the assembly, new methods should be developed that overcome the limitations of the current ones, which are based on the evaluation of point information deducible from the fractured surface or average information taken from the fragment,” the researchers state.

Classification

To date, archaeologists have mainly focused on creating a general vocabulary for classification; they have given relatively little attention to obtaining a method of classification based on replicable observational units. As a result, there exists a wide variety of terms and words describing features that are difficult to recognize.

In recent years, several researchers developed and shared automated methods to assist archaeologists in the classification process. The computer-based methods that perform classification by considering a pottery’s shape and/or dimensions through the 2D profile can be clustered into three principal categories: direct matching, shape descriptor-based, and segmentation-based. However, none of these methods verifies all mandatory requirements proposed by Karasik and Smilansky (2011) for computer-based classification methods.

3D information systems for archaeological pottery visualization and documentation

With increasing use of computer-based methods for analyzing pottery comes the need to store and retrieve archaeological data within computer databases. Currently, relational database management systems are the most widely used in archaeology. However, they do not have a common structure and format, which makes it difficult to exchange data among researchers.

“[It] is necessary to design databases with a structure and format shared with the scientific community, that is complete, capable of handling all information coming from a very heterogeneous set of sources, data structures, [and] content; extensible, able to accommodate other types of information that will be available in the future; efficient, in the use of computing resources; independent of the user’s hardware/software; with minimum redundancy in information representation; [and] easy to consult and to enrich with information,” the researchers state.

The paper, published in Journal of Cultural Heritage, is “A review of computer-based methods for classification and reconstruction of 3D high-density scanned archaeological pottery” (DOI: 10.1016/j.culher.2022.05.001).

Author

Lisa McDonald

CTT Categories

- Art & Archaeology

- Modeling & Simulation

Related Posts

Celebrating the US Semiquincentennial: Ohio Creativity Trail

December 16, 2025

Lithophanes: Dedicated museum sheds light on these porcelain artworks

November 13, 2025