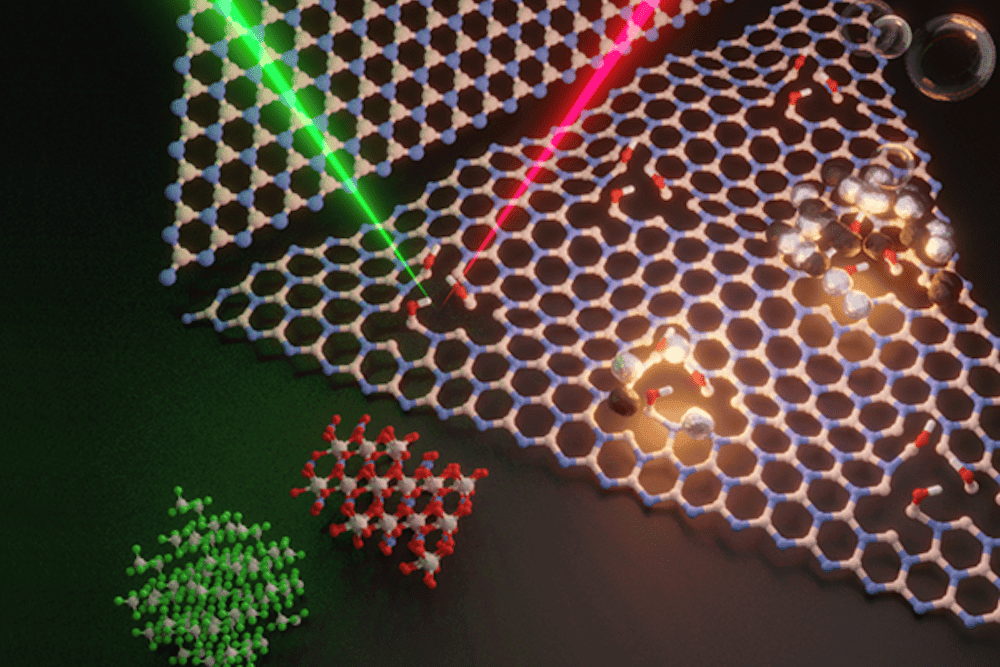

[Image above] Researchers led by The Pennsylvania State University showed cryomilling demonstrates potential to functionalize hexagonal boron nitride through defect engineering. Credit: Elizabeth Flores-Gomez Murray, Yu Lei, and Kazunori Fujisawa; The Pennsylvania State University

While it is possible for graphene to behave as an electrical insulator, hexagonal boron nitride (hBN) is widely considered to be the most promising 2D insulator.

hBN is a layered material that is structurally very similar to graphite. The material is mechanically robust, thermally stable, and chemically inert, and there are several methods to synthesize 2D nanosheets of hBN.

Despite these benefits, researchers are somewhat hindered in applications due to difficulties with functionalizing hBN, or attaching molecules or nanoparticles to the hBN surface to alter its physical or chemical properties. This difficulty stems from the atomic bonds found in hBN. While graphite and hBN are structurally similar, graphite contains nonpolar covalent bonds between the carbon atoms, whereas hBN features highly polar covalent bonds due to the electronegativity difference between the boron and nitrogen atoms.

Researchers have explored different ways to functionalize hBN, such as through reduction reactions. In a recent open-access study, a group led by researchers at The Pennsylvania State University tried a different approach—defect engineering.

Defect engineering refers to techniques to control defects in a material’s structure and/or purposely introducing defects to trigger specific functions. It has emerged as a primary approach to tailor the physicochemical properties and extend functionalities of layered materials.

Researchers have faced some challenges using defect engineering on hBN because of the material’s mechanical robustness, which makes introducing defects into the structure a labor- and/or energy-demanding process. For example, studies to introduce defects through ball-milling show it is a scalable approach, but the prolonged milling time (more than 20 hours) may lead to unwanted contamination from the milling environment.

In the open-access paper, the researchers suggest that cryomilling, or ball-milling in a cryogenic environment (nitrogen at 77 K), may improve the potential of ball-milling to functionalize hBN.

Manufacturers have widely used cryomilling to obtain fine-grained metallic nanostructures with improved mechanical properties. From this application it is known that maintaining the cryogenic environment can significantly suppress undesirable side reactions such as oxidation plus shorten the milling time and lead to a finer grain structure. Researchers have also used cryomilling to unzip carbon nanotubes into graphene, showing the technique’s potential to break covalent bonds and create defects in 2D materials.

In their study, the researchers used cryomilling to introduce vacancies into bulk hBN. The vacancies served as reactive sites to reduce metal cations—specifically platinum—on the hBN surface.

Platinum is used as a catalyst in many types of practical chemical reactions. However, the platinum atoms that perform the conversion usually are on the surface, while the ones below serve as structural support. The researchers hoped that by using defective hBN as structural support, it would expose more of the platinum atom to perform chemical reactions.

The researchers reduced bi-metallic silver–platinum subnanoclusters on the defective hBN, and the material showed excellent activity when used as a catalyst for the hydrogen evolution reaction, which is used in hydrogen fuel generation.

“This superior performance is attributed to the robust anchoring of atomically dispersed Pt atoms and the synergetic effects among AgPt and d-BN [defective boron nitride],” they write.

In a Penn State press release, postdoctoral scholar Yu Lei says that the most difficult part of the project was convincing the research community that hBN could be activated and used as the catalyst support.

“During the process of reviewing our study, additional experiments that were suggested by the reviewers improved the work and help to convince the community,” she says.

The open-access paper, published in Materials Today, is “Low temperature activation of inert hexagonal boron nitride for metal deposition and single atom catalysis” (DOI: 10.1016/j.mattod.2021.09.017).

Author

Lisa McDonald

CTT Categories

- Basic Science

- Material Innovations

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026