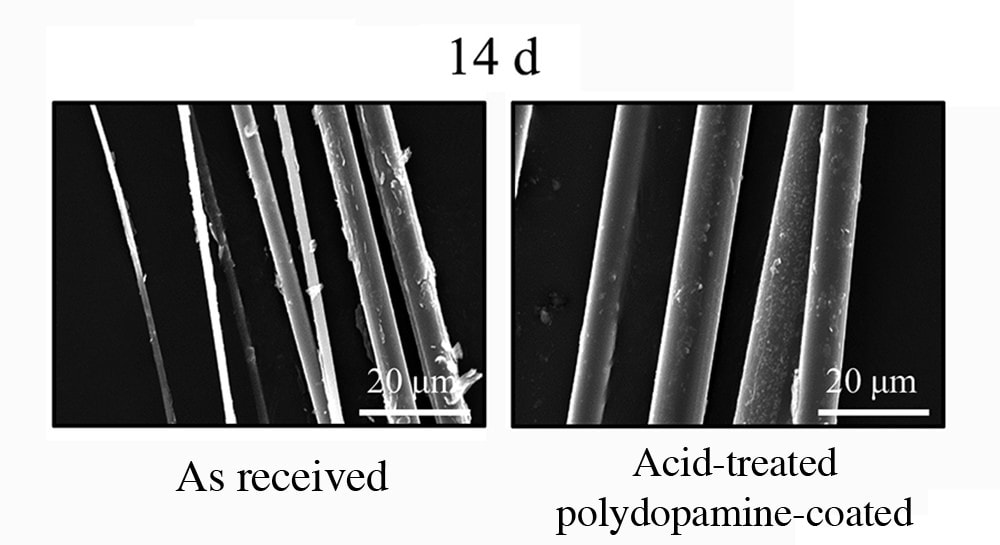

[Image above] An optimized combination of acid treatment and polydopamine coating was able to recover approximately 85% of a phosphate glass fiber’s initial strength. Credit: Parsons et al., International Journal of Applied Glass Science (CC BY 4.0)

There is no question that health care is a potent market for ceramic materials, especially in the dental field (I have a zirconia crown myself). At ACerS, the increasing interest in ceramics for medical applications is obvious, as evidenced by the launch of the Bioceramics Division along with the rising number of articles devoted to the topic.

Among the various potential applications of ceramic materials in health care, bone replacement has yet to reach its full potential. More specifically, researchers have yet to develop a material that can act as a temporary bone in the short-term, promote growth of natural bone to replace it, and be absorbed by the body as the natural bone grows. These three requirements seem to be in opposition to each other—and that’s just the beginning.

Bone replacements must optimize from among many properties. They must

- Be biocompatible, so as to not create an immune response (infection, rejection),

- Be strong and flexible, and

- Be porous enough to allow bone cells to flow and promote formation of blood vessel (angiogenesis), with a surface that provides places for bone cells to land and form bones (osteoconductive).

Ideally, bone replacements also can produce bone cells (osteogenesis), often through the use of donor bone or stem cells as an additive. Additionally, bone replacements should act as an initiator (osteoinductive) to help the body’s natural bone forming materials assemble properly.

The most effective bone replacement therapy today is using a person’s own bone harvested from another location in the bone graft. This technique is expensive, painful, and risky because of there being two surgeries. Alternatively, using bone material donated from another human (or cadaver) or animal meets many of the requirements, though rejection and infection are strong risks. These risks are reduced with sterilization; however, the osteogenesis and osteoinduction properties are greatly reduced. A number of synthetic materials are currently on the market, but none of them can fulfill all the requirements.

Because of the drawbacks associated with current methods, researchers started focusing on creating composites using multiple materials. And a recent open-access paper in the Phosphate Glasses special issue of International Journal of Applied Glass Science focuses on improving one such composite with the use of bioglass phosphate fibers.

Phosphate glass fibers have good initial strength and are bioabsorbable. Unfortunately, the processes that lead to bioabsorption reduce the fiber diameter and the strength of the fibers very rapidly, leading to premature fiber pull-out and breakage. Methods such as annealing fibers are known to stabilize the mechanical properties, though with reductions in initial strength.

The strength of a fiber (its resistance to breakage) is a result of a net compressive stress state at the outer edge of the fiber. Any flaws in the fibers are drawn closed by the compression, thus it is difficult for larger cracks to form. However, as the surface erodes in an aqueous environment, the compressive layer is lost and cracks can more readily form, leading to breakage at lower external stress levels. To make the situation worse, the compressive stress state promotes that same erosion. Annealing reduces the internal stresses of the fiber, which slows the surface erosion and helps retain properties longer. But annealing tends to create surface flaws, and without the compressive “healing” ability, more and faster cracks lead to the lower initial strength.

In the recent study, researchers from the University of Nottingham (U.K.) and Mansoura University (Egypt) explored methods for stabilizing the fiber surface after annealing to take advantage of the long-term benefits while minimizing the issues that lead to reduced initial strength. In their work, they acid etched the annealed fibers to expose pristine glass surfaces and coated the surface with polydopamine, a promising biomaterial know to adhere well to inorganic materials and form nanoscale coating thicknesses.

The results of their studies are rather impressive. For their best combination of processing parameters, the median initial strength of the processed fibers was around 15–20% lower than the as-received fibers. That may not sound great, but the initial strength of annealed fibers was 50% lower. Their processed fibers were both shelf-stable and stable with immersion in water for up to two weeks (the diameter and strength remained relatively constant under these conditions).

The researchers also discussed the scalability of various aspects of their process. Their annealing, cooling, acid etching, washing, and coating processes can all be performed continuously. Furthermore, they etched the phosphate glass fibers in relatively mild hydrochloric acid, which is significantly less hazardous and more environmentally friendly than hydrofluoric acid needed to etch silicate glass.

While this study shows the results of early stage research, the results show promise for commercialization of fiber reinforcements for larger-sized bone replacement composites. I look forward to seeing more about this product and processing method, including performance of composites that use these coated fibers.

The open-access paper, published in International Journal of Applied Glass Science, is “Improved phosphate-based glass fiber performance achieved through acid etch/polydopamine treatment” (DOI: 10.1111/ijag.13672).

Author

Jonathon Foreman

CTT Categories

- Biomaterials & Medical