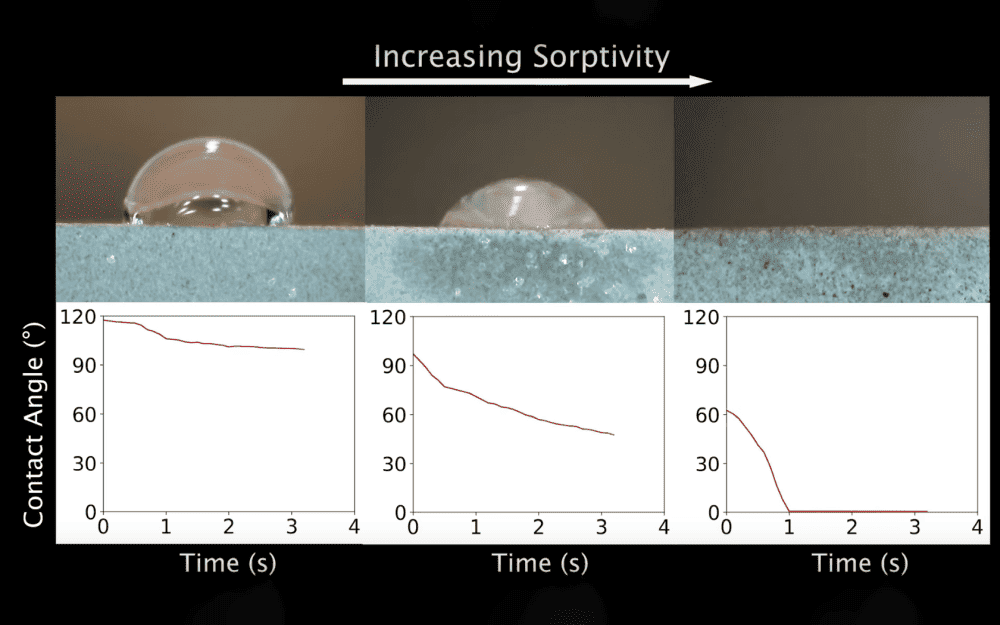

[Image above] Screenshot from a video showing how water droplet contact angle affects cement surface sorptivity. Credit: NewsAtIllinois, YouTube

If we are to achieve the goal of a net-zero future, reducing emissions in the cement and concrete sectors is a must—the industry is responsible for about 8% of global greenhouse gas emissions, after all.

But to effectively reduce emissions, we need to be able to accurately estimate the impact that various measures have on emissions. And as discussed on CTT earlier this month, such evaluation is difficult for several reasons, including the complexity of gathering data on potentially infinite concrete formulations.

The length of time that it takes to gather data on concrete performance is another barrier. For example, the ability of cement pastes to absorb water is a key test to predict the durability of cementitious systems. The more porous a cement paste is, the more water it will absorb, ultimately leading to corrosion of the embedded rebar in reinforced concrete.

The standard test used to determine the “sorptivity” of concrete (ASTM C1585), i.e., how much water the sample absorbs and transmits, involves exposing a sample to water and then continuously measuring its weight change for several hours, if not days.

While automated techniques have been proposed to make the experiment less laborious, these techniques still require several hours of operation.

“Hence, there is a need to develop an automated test, which can also reduce the time associated with sorptivity measurements,” researchers write in a recent open-access paper.

The researchers are ACerS members Nishant Garg, civil and environmental engineering professor at the University of Illinois Urbana-Champaign, and his graduate student Hossein Kabir. In their study, they proposed a rapid characterization method for cementitious pastes based on surface wettability, which they say can result in reliable estimation of initial sorptivity in cementitious systems.

Their method involves using computer vision to see how quickly a single water droplet is absorbed into a sample’s surface within the first few seconds or minutes. Crucially, their test accounts for the angle at which water droplets contact the surface.

“The dynamics of absorption change quickly while the water droplets change shape on the surface,” Garg says in a university press release.

Credit: NewsAtIllinois, YouTube

Credit: NewsAtIllinois, YouTube

Garg and Kabir created more than 60 unique cementitious paste samples using several different ASTM Type 1 cements. After gathering surface wettability data on these samples, they explored whether any meaningful correlation could be established between this data and the sorptivity of cementitious systems.

They determined a fairly good correlation exists between their results and the results from the conventional ASTM C1585 test method. However, they note that this correlation applies only to the initial sorptivity values and not the secondary sorptivity values of the system.

“This observation is likely because this rapid test is based on capillary absorption, and thus cannot be used to estimate the secondary sorptivity (moisture diffusion through gel pores) of cementitious materials,” they write.

Additionally, because the tests were conducted on cementitious pastes, the findings are limited to binders and paste systems. Garg and Kabir plan to explore whether this method can be extended to concrete samples.

Despite these limitations, the new method—which can be conducted on a device that costs less than $200—is a promising example of how the cement and concrete industry can move toward rapid, automated, and affordable quality control of their materials.

The open-access paper, published in npj Materials Degradation, is “Rapid prediction of cementitious initial sorptivity via surface wettability” (DOI: 10.1038/s41529-023-00371-4).

Author

Lisa McDonald

CTT Categories

- Cement