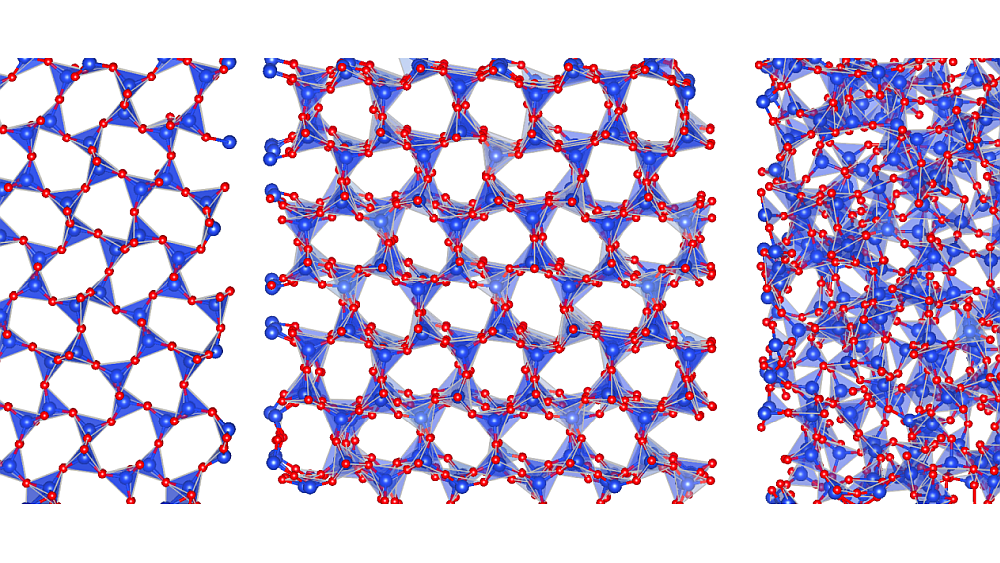

[Image above] Refractories are essential for all high-temperature industrial processes—the challenge is making sure governments recognize that fact. Credit: HarbisonWalker International, YouTube

The concept of “essential” has garnered new consideration over the past few months as local and federal governments mandate which businesses and industries are allowed to continue operating during the global COVID-19 pandemic.

While a lot of discussion focuses on businesses that directly interact with the public—such as grocery stores and post offices—there are equal levels of discussion taking place for industries more hidden from public view, such as steel and glass.

For policymakers, the importance of steel, glass, paper, and other materials is readily apparent, as we see these materials in application every day. However, there is one sector of materials that some governments overlooked initially when mandating essential industries—refractories.

Refractories are ceramic materials that are essential for all high-temperature industrial processes because they provide mechanical strength, protection against corrosion, and thermal insulation.

The World Refractories Association (WRA), a nonprofit organization consisting of six major refractory industry associations and 16 multinational companies, sums up the ubiquity of refractories in industry well on their webpage: “The lining of every single reactor, transport vessel or kiln uses a wide range of refractory products including bricks, monolithics and high-temperature insulation wool.”

The WRA video below details the industry’s impact in more depth.

Credit: Cerame-Unie, YouTube

When governments began mandating closures of nonessential businesses and industries, the WRA published a letter stating strongly their position that refractories be allowed to remain open.

“In the context of COVID-19, our customers in the steel, aluminum, copper, glass, chemicals, energy, waste management and pulp & paper industries are directly responsible for supplying the primary materials used to produce desperately needed items such as hospital beds, ambulances, respirators, face masks, and other medical devices. Their production processes cannot occur without refractories, even in the short term,” the letter reads.

In an IMFORMED post discussing the impacts of COVID-19 on various industries, IMFORMED director Mike O’Driscoll highlighted some of the struggles and successes refractory companies have faced in striving to be deemed essential.

“On 26 March, leading US refractory manufacturer HarbisonWalker International (HWI) announced that it had received written confirmation from Tom Wolf, Governor of the Commonwealth of Pennsylvania, that its application to continue business operations at physical locations had been accepted and approved …

What prompted HWI’s application to state authorities was that companies listed in the business category of ‘Clay Product and Refractory Manufacturing’ had been ordered on 19 March to close physical operations.

However, steel, aluminium, pulp and paper, cement, plastics, rubber, and chemicals manufacturers are permitted to remain open in the USA. Thus HWI was able to demonstrate, and successfully, that refractory products and services supplying those industries are absolutely essential to their manufacturing processes.”

Mike O’Driscoll, IMFORMED

In contrast, the refractory industry in India has not been so lucky. Unlike the steel industry, the refractories industry is not included in India’s Essential Services Maintenance Act of 1981 and so was closed when steel companies were allowed to remain open.

In a Business Insider article from early April, Indian Refractory Makers Association chairman Parmod Sagar described the necessity of reopening refractory companies. “All steel plants are carrying some inventory ranging from 10–15 days. But they need to be replenished and every day we are getting calls from major steel manufacturers regarding supply of refractories,” he says. “Even if we start production, it takes about 5–8 days from the start of process to delivering the end product to steel makers.”

For refractory companies that have successfully stayed open or reopened during this time, they are striving, like many industries, to adhere to World Health Organization recommendations and directives as well as national, regional, and local organization guidelines concerning COVID-19. For examples of the refractory industry’s response, check out this recent WRA Q&A column.

What long-term effects will COVID-19 have on the refractory industry? Though we cannot know for certain at this point, the topic will surely be discussed at ACerS St. Louis Section and Refractory Ceramics Division Symposium on Refractories meeting, which is now scheduled for Sept. 8–10, 2020. Consider joining us then!

Author

Lisa McDonald

CTT Categories

- Refractories