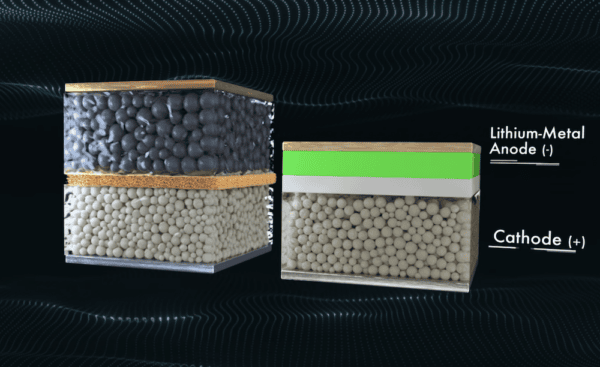

[Image above] A video by solid-state battery research company QuantumScape describes how solid-state batteries (right) compare to conventional lithium-ion batteries (left). Credit: QuantumScape, YouTube

For environmental scientists, tomorrow is one of the most important STEM-themed holidays of the year—Earth Day!

For the past 51 years, people have recognized April 22 as a time to demonstrate support for environmental protection. Earth Day now includes a wide range of events coordinated globally by EARTHDAY.ORG, which works with more than 75,000 partners in over 190 countries.

Materials scientists play a big role in helping the planet by developing new environmentally friendly materials, processes, and technologies. Today, we look at the work being done by one of ACerS Corporate Partners to revolutionize batteries for next-generation electric vehicles.

The promise of solid-state batteries

Solid-state batteries are batteries that use a solid electrolyte rather than the liquid or polymer gel electrolytes found in conventional lithium-ion batteries. Solid-state batteries, which are typically lithium-based, show great promise to solve some of the challenges of conventional batteries, including being lighter weight with greater energy density, extended range, lower cost, and faster recharge times.

Credit: QuantumScape, YouTube

However, building solid-state batteries for real-world applications is a difficult task for several reasons (see video below). Likely the most prominent reason, though, is the formation of lithium dendrites on the anode over long-term cycling. These rigid tree-like structures eventually pierce the solid electrolyte, causing the battery to short-circuit and experience thermal runaway, a serious safety problem.

Credit: QuantumScape, YouTube

Researchers have experimented with several different materials for the solid electrolyte and electrodes to mitigate dendrite formation (check out the September 2019 Bulletin for examples). In recent months, several startup companies researching solid-state batteries for electric vehicles have entered public notice, such as California-based QuantumScape.

QuantumScape: Pursuing a solid future

QuantumScape is a battery research company founded in 2010 by Jagdeep Singh, Tim Holme, and Fritz Prinz.

Singh, a serial founder who previously launched four other startups, became interested in batteries for electric vehicles following the launch of Tesla Motors’ first car, the fully electric Roadster, in 2008. He started attending lectures at Stanford University and met professor Prinz and graduate student Holme, who were working on an all-electron battery. The material that was to underpin their all-electron battery—a type of quantum dot with distinctive electrical properties—served as the inspiration for the name of the company they eventually founded.

Within a year of founding QuantumScape, the trio decided to discard quantum dots and pivot to exploring solid-state batteries instead. Fortunately, the company’s investors were on board, and they ended up bringing on more investors, notably the motor vehicle manufacturer Volkswagen.

From 2010 to 2015, the company ran “millions of tests” to identify a material for solid electrolytes, according to Holme in a Bloomberg article, and finally found two possibilities that seemed resistant to dendrites. After fast-tracking work on these two materials, they settled on one by the end of 2015 and spent the next five years perfecting it.

Details about the solid electrolyte are scarce—the company will only confirm it is made from some sort of dendrite-resistant ceramic and that some liquid remains in the cathode, though the goal for future iterations is to remove the liquid entirely. Performance data released by the company in December 2020, however, claims the current version of the battery can enable up to 80% longer range compared to today’s lithium-ion batteries and can charge up to 80% capacity in just 15 minutes.

(It is important to note that the performance data is based on individual cells rather than complete batteries. In practice, about 100 thin cells will be stacked together to form a full cell that is the size of a deck of cards.)

Currently, QuantumScape says it is nearly three years away from putting its battery in test cars. There are plans to build a pilot manufacturing plant by 2023 in San Jose, California, where test cells can be made for various automakers, and also plans to build a large-scale factory by 2024 in an undisclosed location as a joint venture with Volkswagen.

To prepare for these plants, QuantumScape announced last September that it would be going public through a merger with a special purpose acquisition company. “QuantumScape believes the proceeds from this transaction will fully fund the company through the start of production via its joint venture with the Volkswagen Group,” the announcement explains.

Learn more about QuantumScape’s journey to develop solid-state batteries in this recent Bloomberg Green article.

Besides QuantumScape, Colorado-based Solid Power is another notable startup developing solid-state batteries. Like QuantumScape, Solid Power is using a lithium-metal anode and solid ceramic electrolyte for its battery. Last October, it announced the production of prototype batteries with 10 stacked layers, and in December, it announced the production of prototype batteries with 22 stacked layers.

Author

Lisa McDonald

CTT Categories

- Energy

- Material Innovations

Related Posts

‘Fairy circles’ may help mark natural underground hydrogen deposits

September 18, 2025