Nuclear power is dead, at least in Germany and Switzerland, and perhaps a few other countries.

But it is alive and well in many other parts of the world, according to a recent article in the Journal of the American Ceramic Society, and is breathing life into power-hungry economies in places like China, Vietnam, and India. Interestingly—perhaps ironically—the UAE and Saudi Arabia are fairly well along in their nuclear power plant planning. In Europe, Finland and France are in building mode and the UK government is backing plans to build 12 new reactors over the next 10 years to replace its aging fleet. Even Japan, which suffered the devastating tsunami and destruction of its Fukushima Daiichi nuclear facility, is slowly and meticulously reactivating several nuclear power plants that were shut down after the March 2011 disaster, according to a web report by the World Nuclear Association.

So, while a few countries take an ostrich-like approach and poke their heads into the sands of denial, researchers in other countries are at work developing new technologies to ensure that nuclear power generation remains a strong contributor to the energy portfolio.

Several requirements drive the need for new technologies since the advent of nuclear power generation more than a half-century ago. They include improved safety and reliability, longer service life, waste disposal, and improved “proliferation resistance.” (This last item relates to “repurposing” of spent or stolen fuel for weaponry.) Every facet of nuclear power generation requires ceramics—from the fuel to the reactor design to the waste containment.

In the US, a recent news story from DOE’s Oak Ridge National Laboratory provides some context. Basically, nuclear fuel design dictates nuclear reactor design. Today’s nuclear fuel design has worked well for the last 60 years. However, as the world saw in Japan, things can go very badly in extreme situations. ORNL scientist Lance Snead says in the story, “In current reactors, a lot of expensive systems are dedicated to ensuring that the fission products from burned fuel do not escape from the plant under any circumstances. As a result, nuclear power plants can’t compete with natural gas plants in terms of cost. Until we develop a less expensive fuel technology, the nuclear industry will lag behind other energy alternatives, and we will continue to burn fossil fuels.”

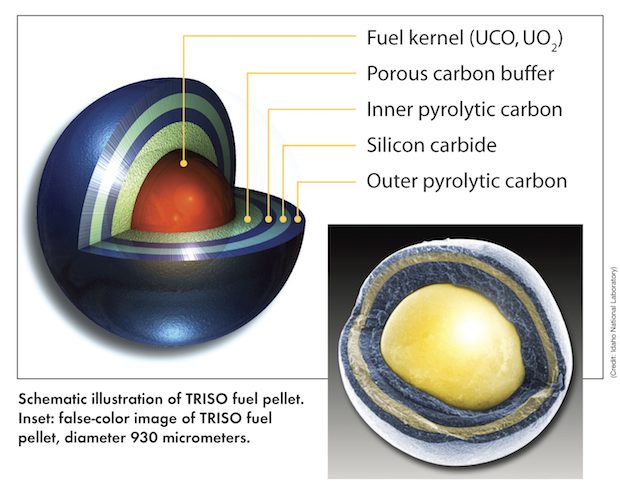

Researchers at ORNL, Imperial College of London, and other locations expect ceramic materials to be important for fuel design as well as reactor design. Starting with fuel, the beating heart of the reactor, the tristructural-isotropic (TRISO) fuel design has been under development for many years. In this design, microspheres of fuel are encapsulated with three layers, such as a carbon buffer layer, dense pyrolytic carbon, and silicon carbide. TRISO fuel designs provide improved safety in extreme situations, self-encapsulation of spent fuel, and longer fuel life, and they are difficult to coopt for evil purposes.

The ORNL team is investigating a new TRISO design they call “fully ceramic microencapsulated fuel,” which grew out of an effort to develop a new fuel design that looks and performs similar to fuels already in service. Silicon carbide offers radiation resistance, steam resistance, and refractoriness.

According to the JACerS article, “Opportunities for Advanced Ceramics and Composites in the Nuclear Sector,” ceramics will be important for many other aspects of fuel technology, from the fuels themselves to design of the fuel component. The focus is on developing new fuels based on thorium oxide, or incorporating difficult-to-burn elements such as neptunium, curium, and americium in mixed oxide fuels. Fuels dispersed in a metal matrix or a ceramic matrix may eventually replace the conventional uranium pellet system.

Besides fuels, new approaches to waste containment are under investigation, for example, nonthermal processes based on calcium aluminate cements or geopolymers. Hydroceramics similar to zeolitized rock have been shown to carry 40–60 wt% waste loads. Previous thermal processes for waste containment involved immobilizing the waste through cementation, bituminization, or vitrification. Researchers are studying a wider range of thermal processes that include hot isostatic pressing, pyrolysis, and novel vitrification technologies such as plasma melting and cold crucible melting, where the frozen glass serves as an in-situ refractory. It may also prove possible to incorporate actinides directly into the crystal structures of some ceramics like zirconlite and some perovskite structures. Additionally, perovskite ceramics such as BaTiO3 and pyrochlores are expected to be useful for containing separated waste streams.

Finally, new fuel designs open the opportunity to redesign the reactor itself. Ceramics are being investigated for use in several reactor components, such as lithium orthosilicate breeder blankets and SiC/SiC or carbon/carbon composites in tokamaks, as well as other regions requiring radiation, steam, and thermal tolerance.

The JACerS paper, written by an Imperial College London group led by ACerS director and Fellow William Lee, notes that ceramic processing will be crucial to incorporating ceramics into all aspects of emerging nuclear technology. The authors conclude their overview with a call to action for the global nuclear research community to share facilities, simulant materials and ion irradiation experiments. They also call for research that combines modeling and experiments to improve understanding of the reactions involved and to expedite discovery of compositions and microstructures that will serve best in the extreme environment of nuclear power reactors.

The paper provides a comprehensive and detailed overview of ceramics for nuclear power generation technology and includes an extensive bibliography. Members can access it for free through the ACerS website. The paper is “Opportunities for Advanced Ceramics and Composites in the Nuclear Sector,” by William Edward Lee, Matthew Gilbert, Samuel Tomas Murphy, and Robin William Grimes, DOI: 10.111/jace.12406.

Author

Eileen De Guire

CTT Categories

- Refractories