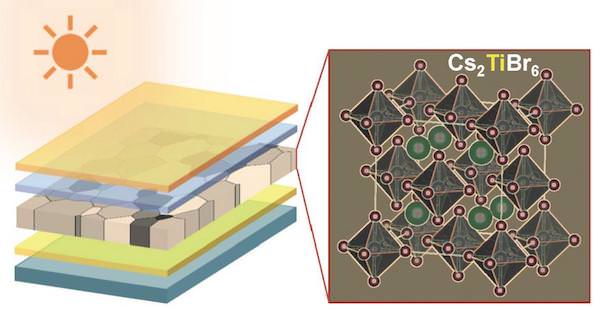

[Image above] Researchers have shown that titanium is an attractive choice to replace the toxic lead in prevailing perovskite thin film solar cells. Credit: Padture Lab, Brown University

Recent advances in solar technology have led to the use of perovskites—a lower-cost alternative in the development of photovoltaics. Researchers like them because of their superconductivity and light-absorbing properties, among other advantages.

We’ve written a lot about perovskites in solar research over the past couple of years. And scientific research has evolved from traditional silicon-based solar cells to thin-film technology.

Although perovskites offer several advantages, they do have their drawbacks, including rapid deterioration from moisture, instability, and high toxicity because of the amount of lead they contain.

But now there might be “greener” solar cell technology on the horizon. Researchers from Brown University and University of Nebraska–Lincoln have created a material that replaces lead with titanium that could be used in inorganic perovskite solar cells.

“Titanium is an abundant, robust, and biocompatible element that, until now, has been largely overlooked in perovskite research,” Nitin Padture—Otis E. Randall University Professor in Brown’s School of Engineering, director of the Institute for Molecular and Nanoscale Innovation, and ACerS Fellow—explains in a Brown University news release. “We showed that it’s possible to use titanium-based material to make thin-film perovskites and that the material has favorable properties for solar applications that can be tuned.”

Padture and his team are building on previous research where they discovered desirable properties of titanium-based halide perovskites, such as higher bandgaps, higher stability, and virtually no defects. They determined that perovskites with cesium, titanium, and some halogens were good possibilities for solar cells.

“The next step was to actually make a solar cell using that material and test its properties, and that’s what we’ve done here,” Padture adds in the release.

Other researchers have explored lead-free perovskites using alternative materials such as tin, but tin “rusts easily when exposed to the environment” according to the release. Titanium is a superior metal not only for its rust resistance, but also because its open-circuit voltage of at least 1 V is higher than its lead-free counterparts (0.6 V).

“Open-circuit voltage is a key property that we can use to evaluate the potential of a solar cell material,” Padture adds. “So, having such a high value at the outset is very promising.”

Padture’s team used high-temperature evaporation in developing their thin films, but they continue to search for other lower-cost methods that will use less energy during solar cell production. “We are also looking for new low-temperature and solvent-based methods to reduce the potential cost of cell fabrication,” materials science student and team member Min Chen explains in the release.

And Padture says they are working on methods that are scalable. “The vapor-base method we have used is not necessarily scalable at this time, but it was used for proof-of-concept demonstration,” he writes in an email. “We are developing more scalable methods, including solution processing.”

The team’s work is encouraging for tandem solar cells where the titanium perovskite cell sits on top of the silicon layer to improve overall efficiency. “We’re not looking to replace existing silicon technology just yet, but instead we’re looking to boost it,” Padture says. “So if you can make a lead-free tandem cell that’s stable, then that’s a winner.”

Semitransparent cesium titanium bromide thin film developed by Padture’s team. Credit: Padture Lab, Brown University

He adds that while they continue to explore titanium-based materials, they also are investigating other mixed bromide-iodide compositions. And although titanium is still more expensive than lead, Padture says in the long run it’s more beneficial for the environment. “The lifecycle cost of cheap but toxic materials like lead can be significant—including extra cost incurred in manufacturing, handling, shipping, recycling, environmental cleanup in the case of disasters (fire, flooding), and healthcare in the case of exposure, litigation, etc.”

The paper, published in Joule, is “Cesium titanium(IV) bromide thin films based stable lead-free perovskite solar cells” (DOI: 10.1016/j.joule.2018.01.009).

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Energy

- Environment

- Manufacturing