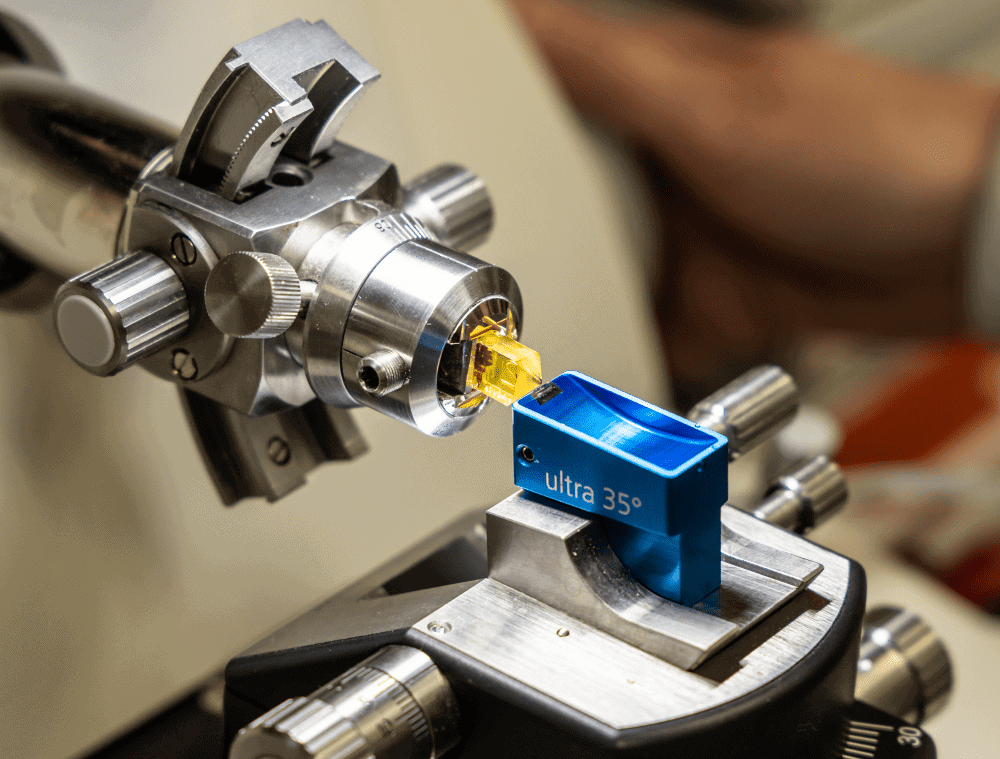

[Image above] Example of a transmission electron microscope. Researchers from the United States and Israel used a variety of imaging techniques to reveal the atomistic structure of M7C3-type carbides. Credit: Oak Ridge National Laboratory, Flickr (CC BY 2.0)

In recent years, numerous political and environmental events have accelerated the growing demands placed on materials scientists to answer challenges in agriculture, healthcare, energy production, communications, and transportation, among other fields.

To keep pace with these demands, experimental methods are increasingly paired with data-driven methods to speed up materials development. These data-driven methods are often fed information about known existing materials systems, and this information allows them to predict other material compositions and structures worth exploring.

Unsurprisingly, these data-driven methods work best for materials systems for which abundant experimental datasets are available for training the algorithm. Otherwise, an algorithm trained on very little data is susceptible to higher test error and lower predictive performance.

Thus, sometimes scientists must run additional experiments before applying data-driven methods to ensure the algorithm provides useful recommendations. Such was the case for researchers from the United States and Israel in a recent study.

The researchers come from New Mexico Institute of Mining and Technology and Technion–Israel Institute of Technology. They used a variety of imaging techniques to reveal the atomistic structure of M7C3-type carbides.

M7C3 carbides (M=Cr, Fe) are extensively used for heat resistance and wear critical applications. However, since the discovery of these carbides in the 1930s, their exact structure has been a source of confusion for scientists.

“A. Westgren [1935] first described Cr7C3 as having a trigonal P31c-structured lattice with parameters a = 1.39 nm, c = 0.454 nm. In 1964, Herbstein and Snyman determined, based on extensive XRD analysis, that the structure is actually hexagonal, belonging to the P63mc space group with the lattice parameters a = 0.6882 nm, c = 0.454 nm. However, in the same year (1964), Fruchart and Bouchaud found that Cr7C3 has a Pmcn-structured orthorhombic lattice,” the researchers write.

The currently accepted structural configuration of M7C3 carbides is the orthorhombic configuration with lattice parameters a = 0.702 nm, b = 1.216 nm, and c = 0.453 nm. However, some publications still refer to the hexagonal configuration of M7C3.

“It is, therefore, our understanding that there is much confusion with regards to the exact Bravais lattice, the derived atomic positions, or even the number of configurations possible for this phase, depending on formation conditions,” the researchers write.

Because of this ambiguity, attempts at using data-driven methods to tailor the carbide’s growth characteristics, stability, and mechanical properties are hindered. The researchers hoped their study could help put this debate to rest so computational efforts can proceed more smoothly.

They used an as-cast AlCrFe2Ni2 with 0.18 wt.% carbon as the model system. The material consisted of four coexisting phases: FCC, B2, BCC and (Cr,Fe)7C3. Images of the (Cr,Fe)7C3 phase were gathered using electron backscattered diffraction, transmission electron microscopy diffraction, and high-resolution scanning transmission electron microscopy.

After gathering the images, they used the CrystalMaker software (version 10.5) to visualize the lattice images and determine which suggested structural configuration matched with the experimentally gathered data.

The researchers concluded that, at least for the composition studied here, there exists only one variant of the M7C3 carbide—the hexagonal P63mc polymorph.

“Our suggested metallic atom coordinates are consistent with all lattice images taken from 9 different zone axes and are consistent with the required symmetry operations, as evident by the Kikuchi patterns,” they write.

Surprisingly, their results indicated that a carbon atom had to be positioned in the middle of each octahedral complex, a location which all previous works considered to be vacant.

“All in all, it is clear that although all M7C3 structures suggested over the years are very similar, there are subtle nuances shown in the HAADF [high angle annular dark field] images that we believe have been fully addressed by our suggested hexagonal structure,” they conclude.

More generally, the researchers believe that the methodology used in this work—i.e., cross-correlated examination of structural data obtained from several complimentary sources combined with simple analytical tools—can help clarify the structure of other materials for which a discrepancy is found in the literature.

The paper, published in Acta Materialia, is “M7C3: The story of a misunderstood carbide” (DOI: 10.1016/j.actamat.2022.117985).

Author

Lisa McDonald

CTT Categories

- Basic Science