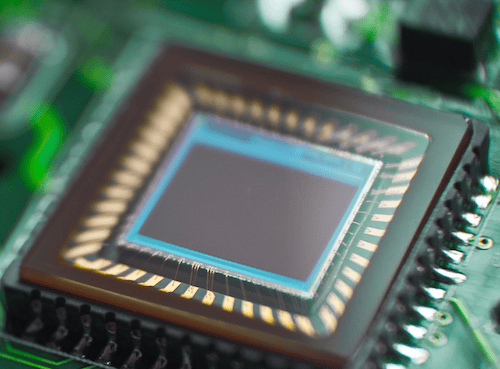

[Image above] Credit: Matt Laskowski; Flickr CC BY-SA 2.0

Next-gen technology just keeps getting smarter. And it all starts with smarter materials.

Smarter materials for windows have led to innovations in energy efficiency. Researchers continue to develop new, smarter uses for glass that keeps us safer on the roads, turns windows into power sources, enables land speed record attempts, repairs human bodies, and helps keep our buildings cooler in the heat.

And the development of advanced materials and technology ultimately leads to a smarter U.S. power grid.

Earlier this year, we reported on research from ACerS member Jay Narayan and his team at North Carolina State University who developed a new technique for creating cubic boron nitride (c-BN) at ambient temperature and pressure—a technique that could lead to advancements across many applications, including power grid technologies.

This week, Narayan and his team—together with scientists at the U.S. Army Research Office—are making “smart technology” news again. This time, they’ve “developed a way to integrate novel oxide materials onto a computer chip, allowing the creation of new smart devices and systems”—materials that, until now, couldn’t be integrated onto silicon chips, according to an NC State University press release.

These novel oxide materials include multiferroic materials, which have both ferroelectric and ferromagnetic properties; topological insulators, which act as insulators in bulk but have conductive properties on their surface; and novel ferroelectric materials, according to the release.

And when it comes to developing better sensors, non-volatile computer memory, and microelectromechanical systems (MEMS), Narayan and his team say these oxides have promise.

“These novel oxides are normally grown on materials that are not compatible with computing devices,” Narayan says in the release. “We are now able to integrate these materials onto a silicon chip, allowing us to incorporate their functions into electronic devices.”

The team’s technique enables integration of these oxides onto two, silicon-compatible platforms—a “titanium nitride platform, for use with nitride-based electronics; and yttria-stabilized zirconia, for use with oxide-based electronics,” the release explains.

The researchers created a variety of thin films that can be combined in different ways to best suit the oxides being used. The role of the thin films is “to serve as a buffer,” the release explains, that connects the silicon chip to the relevant oxides.

These buffers align with the planes of the crystalline structure in the oxides, but also with the planes of the underlying substrate, creating a “communicating layer” between materials.

And that effective communication is the key that unlocks many possible applications, says Narayan.

“Integrating these novel materials onto silicon chips makes many things possible,” Narayan says. “For example, this allows us to sense or collect data, to manipulate that data, and to calculate a response—all on one compact chip. This makes for faster, more efficient, lighter devices.”

But the possibilities don’t stop there. Narayan adds that this development could lead to the creation of LEDs on silicon chips to make “smart lights,” technology that currently relies on the use of sapphire substrates that aren’t directly compatible with computing devices, the release explains.

“We’ve already patented this integration technology, and are currently looking for industry partners to license it,” Narayan adds.

The paper, published in Applied Physics Reviews, is “Multifunctional epitaxial systems on silicon substrates” (DOI: 10.1063/1.4955413).

Author

Stephanie Liverani

CTT Categories

- Electronics

- Glass

- Manufacturing

- Material Innovations