[Image above] Credit: Yilun Li; Rice University

Graphene has probably been one of the most researched materials in the past several years. And it always seems to be making news. A quick search of “graphene” topics we’ve reported on Ceramic Tech Today brings up thousands of results.

Researchers have found many applications for graphene, including light bulbs, headphones, speakers, electronics, de-icers, and many more products.

One of graphene’s biggest challenges is scaling production for commercial use—mainly because it’s hard to control and maintain quality when manufacturing large sheets of it. And quality is important if you want to keep the material’s excellent properties, such as strength, heat conduction, and electrical conductivity. There are a few researchers who are making strides in this area, however, such as those at Kansas State University and the University of Exeter.

Now, an innovative 3-D method of making graphene foam in bulk has been tested in a collaboration between Rice University and Tianjin University, which shows that you don’t need to start with graphene to make a finished product out of it. And you can use a base material that’s available at the local grocery store.

3-D laser printing

Led by James Tour’s group at Rice and Naiqin Zhao’s lab at Tianjin, the researchers used a sintering process and a 3-D laser printer to make centimeter-sized graphene foam blocks out of a carbon source—powdered sugar—along with nickel powder. The laser moves back and forth across the sugar to sinter, or melt, it, while the nickel powder acts as a catalyst to aid in developing the foam, layer by layer.

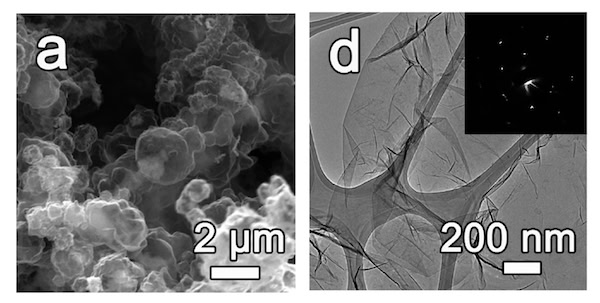

The result is a “low-density, 3-D form of graphene with large pores that account for more than 99% of its volume,” according to a Rice news release.

Credit: Tour group; Rice University

This isn’t the first time the group used the sugar and nickel powder combination to make 3-D graphene foam. Back in February, the group used the same formula to make what they called “rebar graphene”—a foam they reinforced with carbon nanotubes, resulting in a stronger, tougher form of graphene. But the problem with the process was that it took about three hours at 1,000ºC (1,832ºF) using chemical vapor deposition, plus a 3-D mold that needed to be fabricated ahead of time.

Their new 3-D laser process saves not only time, but an enormous amount of energy, because the process can be conducted at room temperature.

“This simple and efficient method does away with the need for both cold-press molds and high-temperature CVD treatment,” Junwei Sha, Tianjin graduate student and co-lead author of the group’s paper, explains in the release.

Tour, a chemist and professor of chemistry, computer science, materials science, and nanoengineering at Rice, says this research is leading to more innovative approaches to scaling up mass production of graphene using their 3–D laser printing technique.

“In this process, we are using sugar as the starting material to make 3-D graphene foams,” Tour explains in an email. “This is just the beginning of 3-D printing of graphene from non-graphene inks. The advanced automation is now being done, and we are incorporating carbon nanotubes to increase the toughness of the 3-D objects.”

“And we are also developing an automated roll-to-roll laminated object manufacturing (LOM) approach. So this first paper is just the beginning.”

Sounds like we’ll be hearing more from Tour’s group in the future. Stay tuned.

The paper, published in ACS Nano, is “Three-dimensional printed graphene foams” (DOI: 10.1021/acsnano.7b01987).

Author

Faye Oney

CTT Categories

- Basic Science

- Manufacturing

- Material Innovations

- Nanomaterials