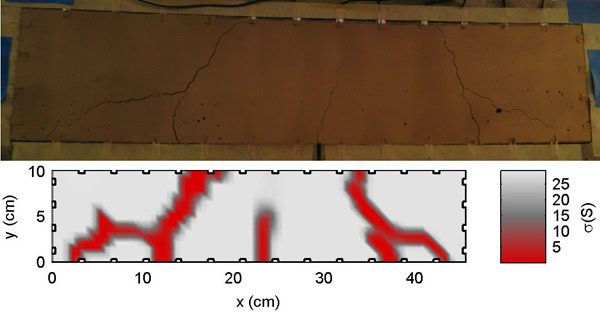

[Image above] A new “sensing skin” technology detects cracks in concrete (top image) and reports when and where the damage took place (bottom image). Click to enlarge. Credit: Aku Seppänen

It’s not the Sixth Sense, Spidey sense, or even common sense, but a new “sensing skin” technology could change the way we’re able to respond to critical (and dangerous) cracks in concrete.

The new tech, developed by researchers from North Carolina State University and the University of Eastern Finland, provides an early warning for structures made of concrete (nuclear facilities, bridges), which helps the right people to take the right action sooner.

“The sensing skin could be used for a wide range of structures, but the impetus for the work was to help ensure the integrity of critical infrastructure such as nuclear waste storage facilities,” says Mohammad Pour-Ghaz, assistant professor of civil, construction, and environmental engineering, in an NC State press release. “The idea is to identify problems quickly so that they can be addressed before they become big problems and—in the case of some critical infrastructure—so that public safety measures can be implemented.”

The sensing skin isn’t skin, but an “electrically conductive” coating of paint that can incorporate even inexpensive conductive materials like copper, which means it, too, is fairly affordable.

Pour-Ghaz, who along with Aku Seppänen co-authored the paper published in Smart Materials and Structures, and the research team applied electrodes to the perimeter of a concrete structure and then coated the structure with the super sensing skin.

With the assistance of a computer (how did we ever live without them?), they “ran a small current between two of the electrodes at a time, cycling through a number of possible electrode combinations.”

The computer not only monitored but also recorded the electrodes’ electrical potential, using the data collected to calculate the skin’s “spatially distributed electrical conductivity.” Areas with a decreased conductivity indicated that the concrete had cracked or experienced damage.

“Determining the location of the damage based on the measured electrode potentials is a challenging mathematical problem,” says Seppänen, an Academy Research Fellow in the Department of Applied Physics at the University of Eastern Finland. “We had to develop new computational methods to more reliably determine where the damage is. Ultimately, I think our work represents an advance over previous algorithms in terms of accuracy.”

So far, the team has only tested its algorithms on a small scale, applying the sensing skin to concrete beams no wider than a meter.

According to Pour-Ghaz, they plan to further explore whether or not the technology will work in large-scale, real-world applications.

The paper is “Electrical impedance tomography-based sensing skin for quantitative imaging of damage in concrete” (DOI: 10.1088/0964-1726/23/8/085001).

Author

Jessica McMathis

CTT Categories

- Cement

- Electronics