[Image above] Credit: Joel Neff, Flickr (CC BY-NC-ND 2.0)

As the family sedan and full-size pickup truck are to the world of transportation, refractories are to ceramics. Both have been around for a very long time; they are dependable and get the job done. And yet they continue to evolve with new capabilities, better performance, greater efficiency, and updates as technology evolves.

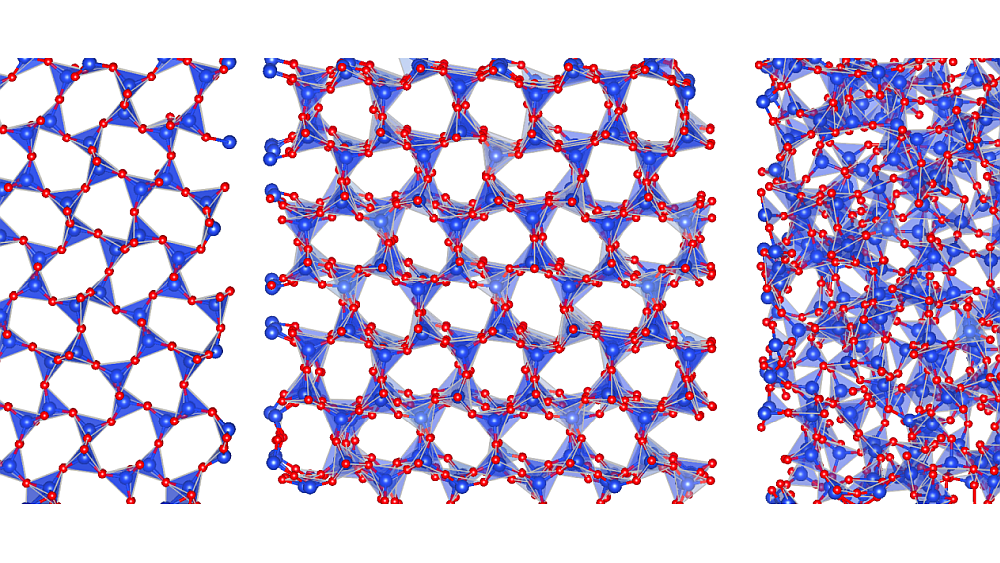

For those who are not familiar with refractories, these high-temperature ceramics are used mainly in high-temperature processing of metals and other ceramics. They serve as insulating kiln linings, kiln furniture (e.g., calcining saggers, setters, and racks), and smelting ladles, among other purposes. Designed for specific applications, refractories must have optimal combinations of mechanical, thermal, and chemical properties, while remaining low mass, low cost, durable, and environmentally friendly. Thus, developing new materials and processing techniques remain critical for this established industry.

As was reported here, the Unified International Technical Conference on Refractories (UNITECR), a biennial global gathering of refractories professionals from industry and academia, was held last month in Chicago, Ill. The organizers arranged two new avenues for curating papers submitted by the meeting presenters. First, the peer-reviewed papers were submitted to the International Journal of Ceramic Engineering & Science (IJCES). The special conference issue includes nine of the UNITECR peer-reviewed articles, which are open access and free to read and download. We look forward to using this type of collaboration with future conferences.

In another nod to open science, all the conference articles, both peer-reviewed and not, are published in an online proceedings collection. As with the IJCES articles, the entire conference collection is free to read and download under creative commons licensing.

Beyond the UNITCR meeting, the ACerS journals publish articles on the science and engineering of refractory materials and components virtually every month. Recently, a small sampling of these articles was gathered into the Topical Collection called “Refractories and UNITECR 2022.” The collection is organized into processing, mechanical properties, corrosion, and new raw materials. These articles just touch on the wealth of research on refractories.

One article that caught my attention, perhaps for its dramatic title, is “Improved explosion resistance of low cement refractory castables using drying agents,” published in IJCES. Exploding refractories are never good. The article explains that unless the low- and high-temperature curing processes are well managed, the water vapor that is driven out of the cements during curing can build within refractories. High pressure can lead to spalling or worse—catastrophic breakdown, i.e., explosion.

Seeing as the article’s authors are industrial researchers, experiments were performed on analytical (small) samples, much larger cubes 0.3 meters on a side (~1 cu ft) weighing 80 kg, and on much larger 400 kg blocks. And yes, they did explode at least one of the largest samples, which you can see in the picture below.

The ∼400 kg LCC blocks after explosion resistance tests, 20°C to 850°C at a rate of 75°C/h. (A) 0.05% PP-1 fiber and (B) 0.05% EMSIL-DRY. Credit: Peng and Myhre, International Journal of Ceramic Engineering & Science (CC BY 4.0)

The article explores different drying agents, with the authors comparing a proprietary polymeric material to standard polypropylene fibers. I learned that the added polymers act as pore formers to provide channels for water removal. The proprietary material, used in the block shown in (B) above, outperformed the standard polymers used in (A). The authors attribute this performance to its lower melting point, which allows for more openness during the critical stages of ebullition (dewatering).

There are many other interesting articles that I’ll leave you, dear readers, to explore on your own. For your convenience, the links to our journal and UNITECR proceedings sites are given below.

Topical collection: Refractories and UNITECR 2022

Author

Jonathon Foreman

CTT Categories

- Refractories