[Image above] With steel ladles facing increasingly severe working conditions, shortcomings of calcium aluminate cement binders are becoming more apparent. Silica sol may be a suitable replacement. Credit: Tad Dunville, YouTube

Things may have been quite heated last Thursday for many couples as they celebrated Valentine’s Day with one another. But things are going to get even hotter for ACerS members—with the release of the March 2019 issue of ACerS Bulletin, which is all about monolithic refractories (available online this Thursday)!

Refractory materials handle extreme temperatures and hostile environments on a daily basis in their roles as linings for furnaces, kilns, incinerators, and reactors.

In anticipation of the new Bulletin, today we take a look at a recent article from the International Journal of Applied Ceramic Technology, which discusses a possible way to overcome shortcomings of calcium aluminate cement (CAC)-bonded castables.

CAC is the most widely used hydraulic binder in corundum-spinel castables, a category of castables that has experienced wide use in recent years due to its desirable qualities, including high resistance to thermomechanical stress and low thermal expansion. In particular, steel ladles are often lined with corundum-spinel because working conditions of steel ladles are increasingly severe.

In the past, steel ladles simply transported liquid steel from furnace to mold. Now, secondary refining processes—such as deoxidation and addition of carburizer and ferro-alloys—commonly take place in the ladle, requiring ladles to handle longer holding times, higher liquid temperatures, and chemical heating.

These recent ladle expectations make some drawbacks to CAC binders more apparent. Particularly, special requirements for curing and drying conditions of CAC-bonded castables can result in castables with low intermediate temperature strength (not good for ladles expected to hold liquid steel for long periods of time). Additionally, as a calcium-based binder, presence of calcium oxide in CAC can damage refractoriness of some ceramic systems.

Are there other binder material options for corundum-spinel castables? According to researchers from the refractory division of Shanghai Baosteel Industrial Technology Service Co. Ltd. in Shanghai, silica sol may be a viable option.

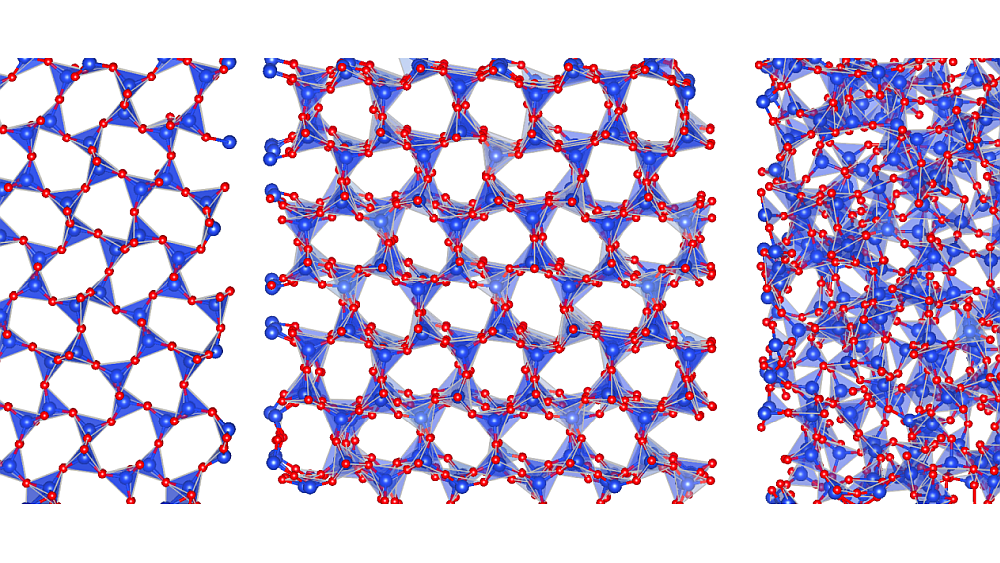

Silica sol is a stable dispersion of nanosized amorphous silica particles that, when used as a binder, surround and bind refractory aggregates through a 3D siloxane bonding (Si–O–Si) network. Compared to CAC-bonded castables, silica sol-bonded castables are calcium-free and present excellent intermediate temperature strength due to this sol-gel bonding mechanism.

A previous study showed silica sol is a suitable binder for alumina and microsilica ceramic systems. In the Baosteel study, the researchers wanted to test suitability of silica sol as a binder for corundum-spinel.

They used three silica sol grades with distinct solid content for the research: H-25 (SiO2 25–26 wt. %), H-30 (SiO2 30–31 wt. %), and H-40 (SiO2 40–41 wt. %). Raw materials for the corundum spinel mixture were adjusted to contain particle sizes of about 43 percent coarse (1–6 mm), 29 percent medium (0–1 mm), and 28 percent fine (≤90 μm).

After dry mixing raw materials and then wet mixing with silica sol, some of the mixture was set aside for flow testing while the rest was cast into samples. Each sample was cured for 24 hours at room temperature, dried at 110°C (230°F) for 24 hours, and then samples were fired at varying temperatures of 400°C, 1000°C, 1500°C, and 1650°C for five hours.

In general terms, the researchers concluded silica sol serves as a suitable binder for corundum-spinel systems. More specifically, though green strength of silica sol-bonded samples was lower than CAC-bonded castables, silica sol-bonded samples demonstrated high strength in medium temperature ranges. Additionally, the researchers say spinel grain size and solid content of silica sol can affect properties of castables, so more research is needed to determine the optimal mixture (research they are currently undertaking).

Keep your eye out here for the March 2019 issue of ACerS Bulletin coming later this week, which will contain more articles on refractories. And if you want even more refractory knowledge than can be contained in a single magazine issue, the ACerS Refractory Ceramics Division and St. Louis Section are holding their 55th annual symposium on refractories next month, March 26–28 in St. Louis, Mo.!

The paper, published in International Journal of Applied Ceramic Technology, is “Properties of silica sol bonded corundum-spinel castables for steel ladles” (DOI: 10.1111/ijac.12885).

Author

Lisa McDonald

CTT Categories

- Refractories