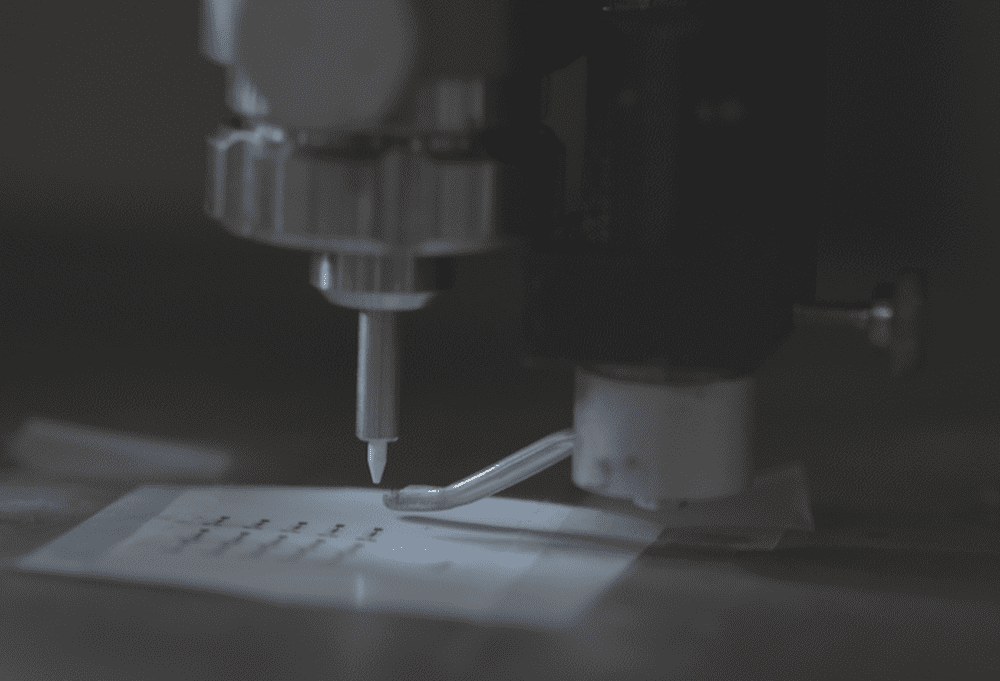

[Image above] Duke University engineers developed a water-only printing process for fabricating printed electronics. Credit: Duke University

The Summer Olympics, one of the most watched sporting events in the world, will be taking place this July and August in Paris, France. Of the many sports happening at this event, artistic gymnastics continually ranks at the top for most-followed sport, particularly by U.S. viewers.

Fans of artistic gymnastics know there are winners for each apparatus as well as an individual all-around winner, who is determined based on the collective score from all apparatuses. This setup means that someone could perform magnificently on several apparatuses, but the all-around title goes to the athlete who performed consistently on each one.

This framework for crowning the best all-around athlete is also how researchers determine the most environmentally friendly product during a life cycle analysis (LCA). During an LCA, researchers score a product’s environmental impacts in several categories, including fabrication, use, and disposal. Though a product may receive top marks in a few areas, the all-around winner will be the product that consistently benefits the environment throughout its entire life cycle.

For example, devices and systems aimed at reducing society’s impacts on the environment, such as renewable energy infrastructure and alternative fuel vehicles, may reduce greenhouse gas emissions during use. However, these products often contain electronic components that require toxic or harsh chemicals for fabrication and disposal, thus negatively affecting the product’s all-around LCA score.

Past CTTs have highlighted several methods to effectively treat wastewater resulting from electronics processing, such as here and here. But researchers are also considering ways to minimize the amount of harmful chemicals required in various fabrication and recycling processes.

In November 2023, CTT showcased the work of researchers at Oak Ridge and Argonne National Laboratories who achieved the ultimate reduction in toxic chemical use. They demonstrated that immersing anode coatings in just water allowed for the complete delamination and reuse of these battery scraps.

Recently, engineers at Duke University also achieved water-only processing, in this case to fabricate fully recyclable printed electronics.

Printed electronics are an emerging market that replaces the traditional vacuum-based processing method with several printing techniques to create electrical devices on various substrates. These electronics are thinner and more flexible than conventional devices, allowing for easier integration into a wider array of products.

Currently, printable electronic inks and their associated print processes tend to rely on environmentally hazardous chemicals, which offsets the benefits of printed electronics in application. To address this problem, the Duke engineers developed the world’s first fully recyclable printed electronics in 2021.

Their thin-film transistor was created using three carbon-based inks: crystalline nanocellulose as the dielectric, carbon nanotubes as the semiconductor, and graphene as the conductor.

While the materials used to create the transistor were environmentally friendly, the Duke engineers noted that harsh chemicals were still required to adequately disperse the carbon nanotubes during processing. Fortunately, they overcame this requirement with the new water-based processing method described in the recent paper.

Previous studies on water-based processing of carbon nanotube inks struggled with bundling and aggregation of the nanotubes. The addition of ionic surfactants to combat this clumping impeded the attachment of nanotubes to the substrate, leading to extended deposition times.

In the new study, the Duke engineers developed a multicycle print and rinse strategy to remove excess surfactant between each printing pass. This approach resulted in desirable nanotube film density on the substrates without lengthy processing times.

While the water-printed transistors’ performance does not match the best transistors currently being manufactured, “they’re competitive enough to show the research community that we should all be doing more work to make these processes more environmentally friendly,” says senior author Aaron Franklin, Addy Professor of Electrical and Computer Engineering at Duke, in a Duke press release.

The paper, published in Nano Letters, is “All-carbon thin-film transistors using water-only printing” (DOI: 10.1021/acs.nanolett.2c04196).

Author

Lisa McDonald

CTT Categories

- Electronics

- Environment

- Manufacturing