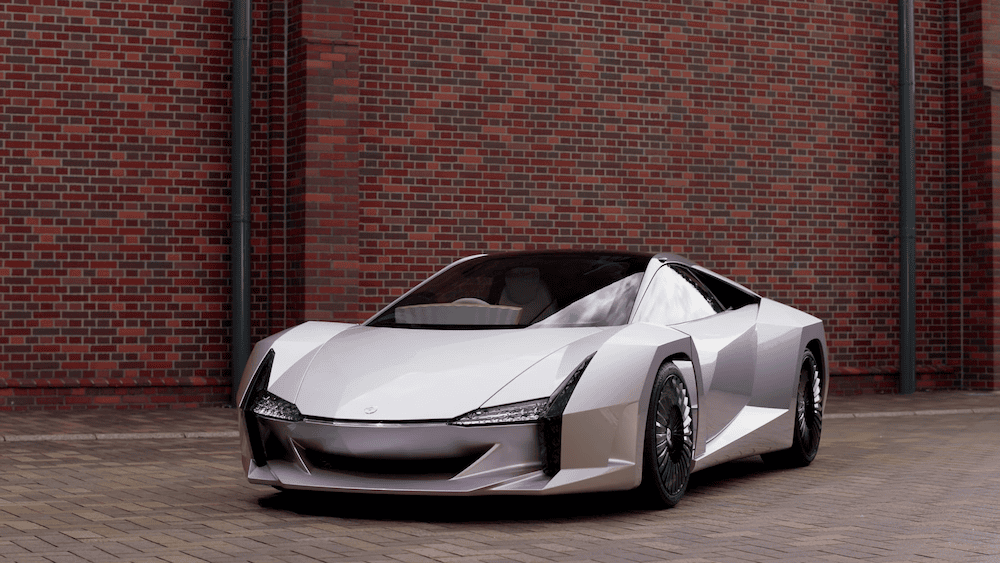

[Image above] Despite recent successes, carbon fiber composites still face challenges hindering their widespread use in vehicles. Could cellulose nanofibers be another option to reduce the weight of vehicles? Credit: kankyosho, YouTube

Last week, we looked at a couple ways to lower carbon emissions in the construction and manufacturing sectors. However, there is another sector that accounts for even more emissions—transportation.

The transportation sector generates the largest share of greenhouse gas emissions in the United States (28.9% in 2017). The emissions come primarily from burning fossil fuels to power vehicles.

One way vehicle manufacturers are looking to lower emissions is by designing vehicle parts from materials that are lighter than traditional steel and aluminum yet equally strong. In particular, carbon fiber has received a lot of attention, as the strongest carbon fibers are ten times stronger than steel and five times lighter.

Today, most Formula 1 racing car chassis are built with carbon fiber composites, and some regular cars and airplanes contain carbon fiber composites as well.

But despite successes with carbon fiber, challenges still hinder the material’s widespread use. It is labor-intensive and expensive to work with, and costs remain high despite industry demand.

Are there other materials similar to carbon fiber that could be used for vehicle parts? In Japan, a group of 22 universities, research institutions, and companies are working together to investigate CNFs. No, not carbon nanofibers—cellulose nanofibers!

Cellulose nanofibers (CNFs) are derived from plants and recycled agricultural waste. CNFs are one-fifth the weight of steel and five times stronger, according to the group’s website.

The Japanese group, called the Nano Cellulose Vehicle (NCV) Project, started in October 2016. The project aims to use CNFs to reduce the weight of automobiles by 10% by 2020.

In October this year, the researchers revealed a prototype of the NCV at the Tokyo Motor Show. CNFs are used across the body, including the doors, roof, and hood, and make the car’s shell up to 50% lighter than shells made from traditional metals. Additionally, CNFs were used extensively in the car’s structural tub.

Nano Cellulose Vehicle prototype at the Tokyo Motor Show. Credit: Press TV, YouTube

More details on the project, and reasons why Japan is the perfect place to conduct wood-based research, are provided in the video below. And if you are interested in how closely cellulose nanofibers compete with carbon fibers, check out this research paper.

This video cannot be embedded on external sites. Click the image above or this link to view the video on YouTube.

Author

Lisa McDonald

CTT Categories

- Nanomaterials

- Transportation

Spotlight Categories

- Member Highlights