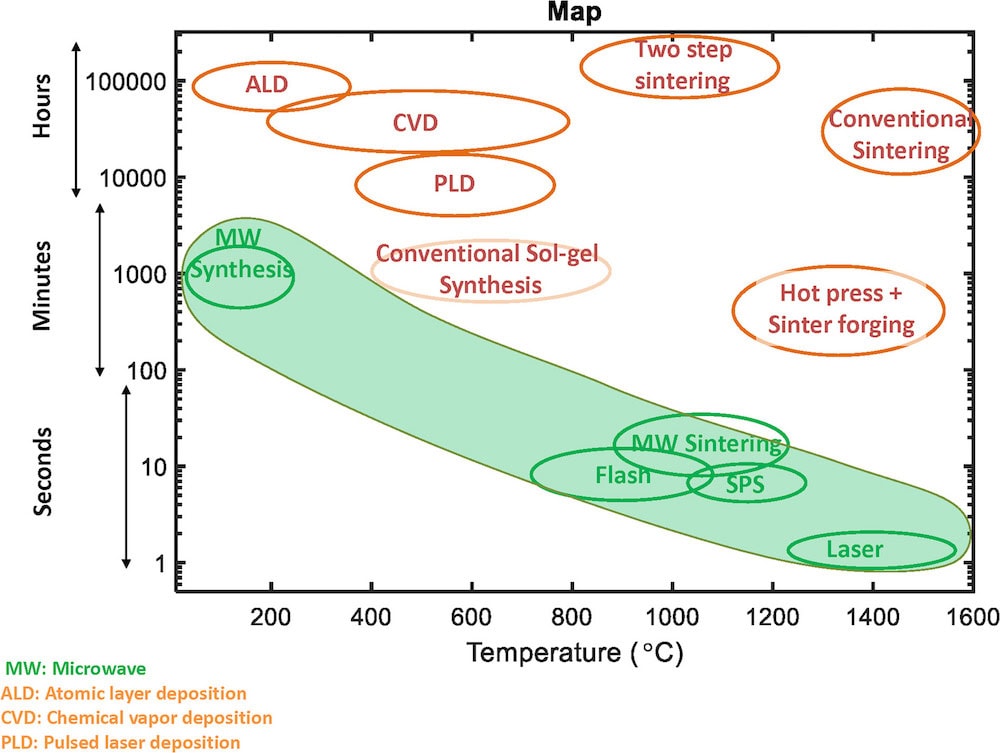

[Image above] Graph comparing the processing time and temperature of traditional and advanced sintering and production methods. The green highlighted methods offer significant improvements over conventional methods, but their mechanisms are not well understood. Credit: Journal of the American Ceramic Society, Wiley

Sintering, or the consolidation of fine particles into dense parts, is one of the oldest and most common ceramic production methods—and it is also one of the slowest and most energy intensive. As such, methods that bring down firing temperatures and cycle times are getting a great deal of attention from ceramic scientists and engineers at university, government, and corporate laboratories around the world.

Field-assisted sintering techniques (FAST) are a class of advanced sintering methods wherein the green (preformed, but not yet sintered) parts are subjected to electrical or electromagnetic fields in order to reduce the sintering temperature and/or time. DC voltage, microwave, and laser fields are the most mature of these techniques.

While engineers are working to implement FAST technologies, scientists are working to understand the underlying mechanisms, that is, the changes occurring at the atomic level, that enable FAST success. Understanding why and how these methods work is crucial for improving consistency of products made with these techniques, and for accelerating their adaption to new materials and systems.

In the January 2019 feature article of the Journal of the American Ceramic Society, scientists from multiple universities reported on a 2-day workshop organized at Carnegie Mellon University that aimed at unraveling the mystery of the interactions of thermal and other energies that occur during FAST. The scientists who attended the workshop and authored the paper are Shikhar K. Jha and B. Reeja-Jayan from Carnegie Mellon University; Xin Li Phuah, Haiyan Wang, and Edwin García from Purdue University; and Jian Luo and Costas P. Grigoropoulos from University of California San Diego and Berkeley, respectively.

Their task at the workshop was by no means a simple one. Field-assisted sintering creates far-from-equilibrium conditions with extremely rapid and complicated changes to ceramics at atomic, micro, and macro scales.

The workshop identified three important areas of discussion: determining whether electrical and EM fields raise temperatures or create defects that drive sintering; developing characterization tools and experiments for simultaneously measuring property and structure changes with adequate spatial and time resolutions; and connecting multiscale models in order to relate atomic-level physics with microstructural and macroscopic changes.

Determining how fields affect sintered ceramics at the atomic level is key to unlocking the mechanism of FAST. Do fields cause the materials to get warmer through increased vibrations or resistive heating? Or do fields move electrons to create chemically-driven changes? It is difficult to say which theory is correct because there are few in-situ and in-operando measurement techniques. However, modeling provides a parallel path to experimentation for uncovering the underlying mechanisms, and allows researchers to predict behaviors for new systems.

The workshop provided insight into the current state of research with robust debate and recent examples of the achievements and limitations of in-situ methods such as TEM, X-ray, and nanoindentation methods. Also discussed were examples of modeling efforts and challenges arising from current models that lack both clear assumptions and knowledge of behavior during transitions at all scale levels.

In summarizing the workshop, the scientists advocated for development of more and better experimental methods and to continue working to bring together different computational tools and techniques that will comprehensively model multiscale phenomena occurring in far-from-equilibrium conditions.

The paper, published in Journal of the American Ceramic Society, is “The effects of external fields in ceramic sintering” (DOI: 10.1111/jace.16061).

This paper is included in the ACerS topical collection on sintering methods, which is located on ACerS Publication Central, and is free access for a limited time. Visit the Topical Collections page at https://ceramics.onlinelibrary.wiley.com/hub/topical_collections.

Author

Jonathon Foreman

CTT Categories

- Basic Science