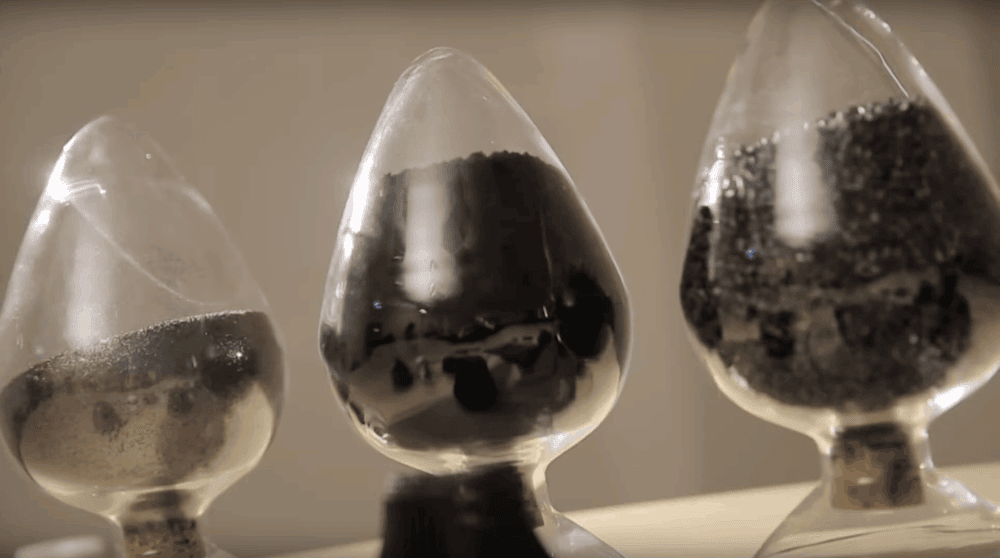

[Image above] Graphene has the potential to revolutionize many applications—if the quality of graphene can be assured. Credit: Enerage Inc., YouTube

Ever since two high-profile studies came out in 2018, researchers have focused a lot of attention on the issue of “fake” graphene in the global graphene market.

“Fake” graphene refers to graphene that contains nonexfoliated graphitic and other nano carbonaceous particles or impurities from the production process, which gives it properties far from those expected of pure graphene.

“Whether producers of the counterfeit graphene are aware of the poor quality is unclear. Regardless, the lack of standards for graphene production gives rise to bad quality of the material sold in the open market. This has been stalling the development of the future applications,” Castro Neto, director of the National University of Singapore Center for Advanced 2D Materials, explains in a press release.

To address these graphene quality concerns, the international scientific and standardization communities have devoted considerable efforts in recent years to develop guidelines for the industry.

For example, the International Organization for Standardization created the ISO graphene terminology standard describing graphene and related 2D materials in 2017, and it established the first ISO technical report on these materials’ properties and associated measurement techniques in 2019.

In January 2021, the Graphene Flagship Standardisation Committee hosted the first in a series of events on what industry needs from graphene standards. And in March, the National Physical Laboratory announced a new ISO/IEC standard it developed with international partners for measuring the structural properties of graphene, bilayer graphene, and graphene nanoplatelets from powders and liquid dispersions.

These guidelines are important steps toward regulating graphene quality. But developing standards only go as far as the characterization techniques available. And unfortunately, most of the recommended techniques for graphene analysis—such as transmission electron microscopy, Raman spectroscopy, and atomic force microscopy—are localized characterization methods, meaning they can only probe small areas and thus limit the ability to characterize the large bulk quantities necessary for commercialized scaleup.

Developing new ways to characterize graphene quality, then, is essential to developing more rigorous standards.

Last November, we covered the work by Ames Laboratory researchers on using low-energy electron diffraction to evaluate graphene quality. Now, a new study by researchers at the University of Adelaide in Australia explores the use of thermogravimetric analysis (TGA).

TGA is a method of thermal analysis in which the mass of a sample is monitored as a function of temperature or time as the temperature changes. “The TGA method, routinely used by the industry for characterization of the thermal properties and impurities of minerals, polymers and carbon materials, is surprisingly overlooked as a characterization method for the quality control of graphene materials,” the researchers write.

So, they aimed to show that TGA can be a “powerful analytical tool” for determining the quality of graphene materials.

They prepared verified control samples of few-layer graphene (FLG), reduced graphene oxide (rGO), and graphene oxide (GO) to confirm the baseline TGA and the first derivative (DTG) characteristics of their bulk powder forms. These characteristics were then categorized into specific analytical parameters and used to screen a series of commercial and lab-prepared samples.

Their results showed that the DTG peaks and temperature of maximum mass decomposition rates (Tmax) values can be linked to the number of stacked graphene layers (very high in graphite) and defects in carbon structures (very high in GO)—characteristics that are essential to determining the quality of graphene materials.

“Based on these results, … we can make the conclusion that the DTG peaks and Tmax values are distinctive and these simple parameters can be used for qualitative identification of FLG, GO, rGO and graphite and their differentiation,” they write.

In the conclusion, they note that the TGA method can be further improved by standardizing TGA measurement conditions through interlaboratory comparisons and machine learning software. However, the potential already demonstrated in this study means TGA may end up “ultimately aiding in identifying previously described ‘fake graphene’ in the growing graphene industry,” they write.

The paper, published in Carbon, is “Unlocking thermogravimetric analysis (TGA) in the fight against ‘Fake graphene’ materials” (DOI: 10.1016/j.carbon.2021.04.064).

Author

Lisa McDonald

CTT Categories

- Basic Science

- Nanomaterials