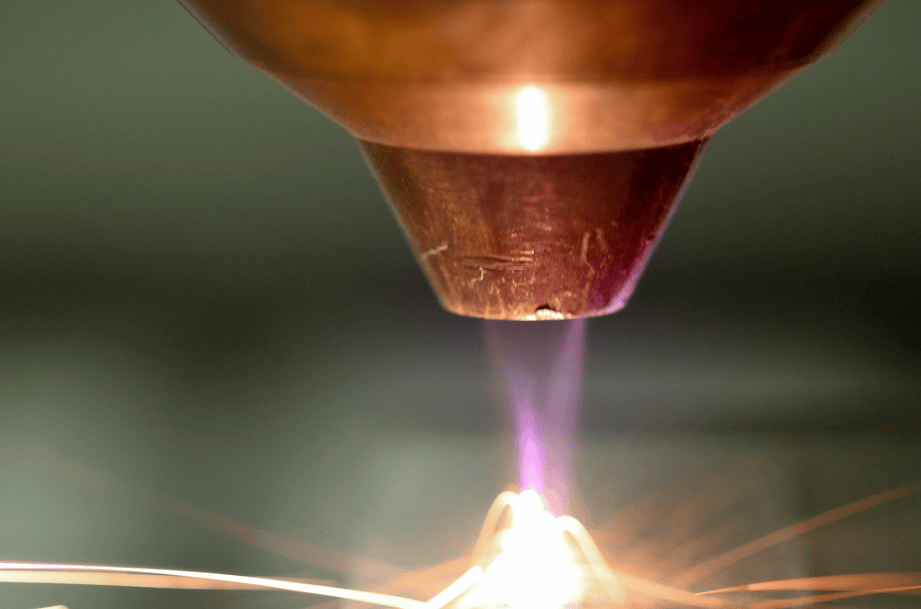

[Image above] Polymer Additive Manufacturing lab at the Manufacturing Demonstration Facility at Oak Ridge National Laboratory. Credit: ORNL; Flickr CC BY-NC-ND 2.0

As we welcome cooler temps after a sweltering summer and embrace the brilliant fall foliage, there’s another reason to celebrate the first week of October—it’s National Manufacturing Day!

Every first Friday of October, manufacturing companies and other organizations all over the country join the movement and host hundreds of thousands of people who want a first-hand look into U.S. manufacturing.

This year marks the U.S. Department of Commerce’s fifth annual Manufacturing Day. But the goal always remains the same: to increase public awareness about what and where manufacturing is in the U.S., provide a pathway toward a new career for individuals interested in the field, and demonstrate manufacturing’s value to the U.S. economy.

Check out this video from Manufacturing Day’s YouTube channel about how your organization can participate!

https://www.youtube.com/watch?v=XzngKiBr93k

Credit: Manufacturing Day (MFGday); YouTube

“Manufacturing Day addresses common misperceptions about manufacturing by giving manufacturers an opportunity to open their doors and show, in a coordinated effort, what manufacturing is—and what it isn’t… Manufacturers will begin to address the skilled labor shortage they face, connect with future generations, take charge of the public image of manufacturing, and ensure the ongoing prosperity of the whole industry,” according to the MFG Day website.

Ceramic and glass professionals understand the importance of a robust manufacturing sector to our country’s economic growth and success.

ACerS established its Manufacturing Division in April 2015 to address the needs of members and prospective members worldwide who work in the ceramics and glass manufacturing industry and its supply chain.

And ACerS is also leading a NIST-funded Advanced Manufacturing Technology project on advanced manufacturing of functional glasses—the Functional Glass Manufacturing Innovation Consortium (FGMIC).

At CTT, we follow and report on the latest manufacturing trends—especially when it comes to ceramics, glass, and materials science. In honor of National Manufacturing Day, we’ve pulled together a roundup of stories that cover three of the latest materials manufacturing trends.

3-D printing new materials leads to more wide-range applications.

Innovations in 3-D printing continue to evolve, with companies like auto manufacturer Local Motors planning to drive mass production of 3-D printed cars through this year.

The evolution doesn’t stop there—it seems like there’s nowhere additive manufacturing won’t go. From 3-D printed concrete to electronics to glass, this technology is changing how we manufacture materials.

- 3-D-printed bioceramic composite offers flexible new hope for bone replacement

- Improving 3-D printed ceramics with ‘fluid dosing and deposition’ technology

- Light-powered 3-D printing technique creates new terahertz lens for better security imaging

More “green” for clean energy means new materials for energy-efficient technologies.

In February, the U.S. Department of Energy launched a $40 million effort to improve materials for clean energy solutions. The new national laboratory-led program—called the Energy Materials Network—will “give American entrepreneurs and manufacturers a leg up in the global race for clean energy,” according to the DOE.

Already in 2016, researchers have invested significant time, cash, and resources into improving existing clean energy technology and developing new materials to change the game.

- Crystals are key when it comes to reducing cement’s carbon footprint

- Transparent wood windows could be key to better energy efficiency

- Just add water: Does adding moisture to perovskite solar cells boost efficiency?

New materials continue to pave the way for next-generation electronics.

Tomorrow’s electronic devices won’t just be more efficient, they’ll be durable enough to bend and stretch without the slightest fracture, all while being fully operational.

From smartphones to wearables to cameras, tech companies and researchers are innovating electronics that are thinner, more durable, and can bend without breaking.

- MXene films provide option for better, thinner electromagnetic shielding for electronic devices

- Is going ‘organic’ the key to flexible, next-gen consumer electronics?

- New liquid light switch could boost power of smaller electronic devices

Join the movement: How will you celebrate National Manufacturing Day, and what manufacturing trends do you think will be buzzworthy in 2017? Share your thoughts in the comments!

Author

Stephanie Liverani

CTT Categories

- Construction

- Electronics

- Energy

- Manufacturing

- Market Insights

Related Posts

Hype cycles: The uphill climb for hydrogen bikes

June 26, 2025