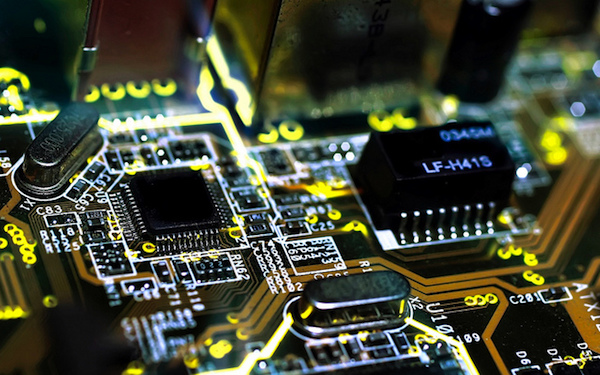

The nearly $4.5 trillion global electronics industry would not exist without ceramics. Ceramic-based components are indispensable in products such as smartphones, computers, televisions, automotive electronics, and medical devices.

Although ceramics have traditionally been considered insulating materials, after World War II, research in material science has led to the development of new ceramic formulations that exhibit semiconducting, superconducting, piezoelectric, and magnetic properties.

Ceramic products used as electrical insulators include spark plugs, hermetic packaging, ceramic arc tubes, and protective parts (e.g., beads and tubing) for bare wires and power lines. These products are primarily used in sectors such as automotive, marine transportation, aerospace, and electricity distribution. Among these products, spark plugs represent the oldest and the most popular. They were first invented in 1860 to ignite fuel for internal combustion engines and are still being used for this purpose today. However, as the automotive industry shifts toward electric and hybrid vehicles, demand for ceramic spark plugs is expected to drop. The main suppliers of these products are directing their know-how in electroceramics toward other components such as ceramic solid-state batteries.

From a market standpoint, passive components are experiencing the most demand. Passive components are referred to as such because they are not able to control the flow of electrons in a circuit, unlike active components (also known as semiconducting devices). Passive components are only used to store or transform energy. Ceramic capacitors represent the bulk of the passive component market and have experienced rapid growth lately due to strong demand from the mobile device and communications sector. These capacitors utilize the insulating properties of a ceramic material (called dielectric) placed between two or more metal layers to store electrical charges. Ceramic capacitors are becoming very small in size, almost microscopic. Recently, multilayer ceramic capacitors (MLCCs) that measure only 0.25mm by 0.125 mm by 0.125 mm have been commercialized.

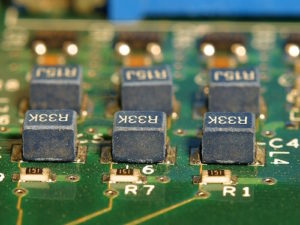

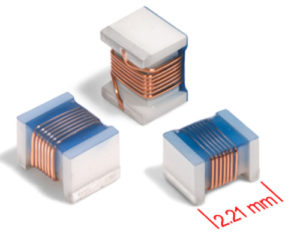

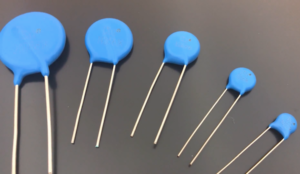

Other types of passive components include fixed and variable resistors (they use ceramics to dissipate energy), inductors (they use a magnetically permeable ceramic to create a magnetic field), and circuit protection devices (they use a semiconducting ceramic to protect the circuit against transient voltage surges).

Piezoelectric ceramics are materials that generate an electrical charge when pressure is applied or change size under an electric field. They are used to transform mechanical energy into electric energy or vice versa. These devices are becoming increasingly popular for use as filters, resonators, transducers, acoustic elements, actuators, and components for pressure sensors. Easy to manufacture in various shapes and sizes, piezoelectric ceramics contribute significantly to the miniaturization of electro-mechanical features and, consequently, are gaining greater penetration in the fields of consumer electronics, robotics, automotive, sensors and instrumentation, and energy harvesting.

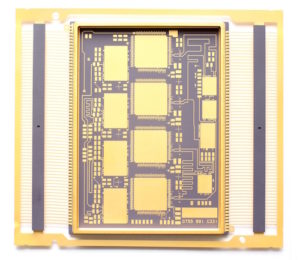

Other types of electroceramics consist primarily of ferrite-based permanent magnets and circuit devices for high-reliability applications (e.g., low- and high-temperature co-fired ceramics, and ceramic electronic substrates).

Within the electronics sector, glass is primarily used to fabricate display panels for televisions, computers, and mobile devices. The unprecedented mass appeal of portable devices has led producers to create ultra-tough glass that does not break when dropped.

Glass powder is also added in thick film paste for metallization of electronic components, whereas glass seals are used in certain applications to protect electronic devices from the environment. Flexible glass is being produced for fabrication of flexible devices, such as organic light emitting diodes (OLEDs).

The main applications of ceramics and glass in electrical and electronic applications are illustrated in the table below.

Main applications of ceramics and glass in electrical and electronic applications

| Where? | What? | Examples |

|---|---|---|

| CERAMICS | ||

| Transportation electrical systems | Spark plugs | 1  |

| Power distribution | Protective parts for power lines | 2  |

| Electronic circuits | Capacitors | 3  |

| Resistors | 4  |

|

| Inductors | 5  |

|

| Circuit protection devices (for example, metal oxide varistors) | 6  |

|

| High and low-temperature co-fired ceramics | 7  |

|

| Electromechanical applications | Piezoelectric devices | 8  |

| Audio systems | Magnets | 9  |

| GLASS | ||

| Displays | Rigid panels | 10  |

| Flexible panels | 11  |

Image credits: 1. Pixabay; 2. Pixabay; 3. Pixabay; 4. Pixabay; 5. Coilcraft, Microwave Journal; 6. Kingtronics Kt, YouTube; 7. Konstantin Lanzet, Wikimedia; 8. ydaultrasonic, YouTube; 9. Omegatron, Wikimedia; 10. ZGXoff, YouTube; 11. CNET, YouTube

Join The American Ceramic Society

Become an ACerS member and enjoy the additional benefits of belonging to a global community of ceramic and glass scientists, researchers, materials scientists, professors, students, and manufacturers.