[Image above] Review articles are important research contributions, too! Credit: PxHere

As important as it is to pursue new discoveries, doing so in a constructive manner is difficult if you lack background on what has already been done. And sometimes unburying and elaborating on research abandoned years ago revolutionizes fields of research that otherwise would be considered dead-end streets.

Keeping up-to-date in your field of research, though, can be a time-consuming and overwhelming task. Which is why review studies like the recent one conducted by Zhen Wu, Luchao Sun, and Jingyang Wang on rare-earth silicates are so important.

Wang, a member of the ACerS Board of Directors and distinguished professor and deputy division head of the high-performance ceramics division at Shenyang National Laboratory for Materials Science, has performed numerous studies on rare-earth silicates, with a few articles already published this year. However, for this post, we highlight the main points from the review article he published with Wu and Sun that summarizes progress on optimal processing and properties of highly porous rare-earth silicate thermal insulators.

(For those who wish to learn more, the review article is open access, so you can read the whole article!)

Porous ceramics are good—how do we make them great?

Porous ceramics make good thermal insulators due to several advantageous characteristics, including good high-temperature resistance, good corrosion resistance, low density, low thermal conductivity, high permeability, and high specific strength.

However, each porous ceramic does not offer every advantage. The porous ceramics commonly used for thermal insulators—silicon dioxide (SiO2), aluminum oxide (Al2O3), mullite, and yttria-stabilized zirconia (YSZ)—each have drawbacks. For example,

- SiO2 has low compressive strength and operating temperature,

- Al2O3 has high thermal conductivities,

- Mullite has low strength,

- YSZ has high sintering linear shrinkages and high density.

To classify as a great thermal insulator, a material should have a high melting point, good thermal stability, and low thermal conductivity. And what do you know—rare-earth silicates exhibit high melting point, low thermal conductivity, and good thermal and chemical stability at high temperatures!

Because of these properties, porous rare earth silicate ceramics have become a focus in the field of porous ceramic thermal insulator research. For the review article, the authors focus on yttrium (di)silicates and ytterbium silicates as examples of porous rare-earth silicates.

Preparing rare-earth silicates

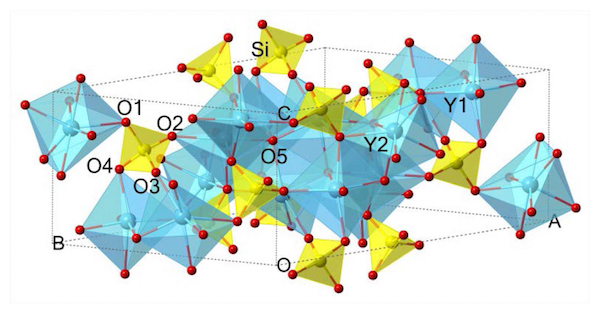

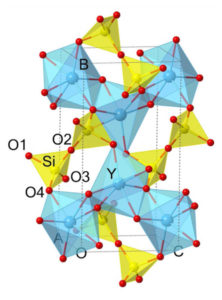

The authors reference two articles to state that rare-earth silicates come in two stable phases: RE2SiO5 (monosilicates) and RE2Si2O7 (disilicates).

For monosilicates, the authors divided research studies on porous monosilicate preparation into two broad categories: direct sintering (for example, using Y2SiO5 powder as the raw material), and in-situ reaction sintering (for example, using Y2O3 and SiO2 powders as the raw materials). After describing in-depth the various preparation processes that fall under each category, the authors concluded that as far as porosity and density are concerned, “the in-situ sintering process could result in quite a high porosity and very low density, compared to those of all the direct sintering processes.” Additionally, “the in-situ sintering process could realize light weight, low thermal conductivity, and high strength simultaneously.”

For disilicates, the authors focused on the γ-Y2Si2O7 polymorph of Y2Si2O7, which is stable at both room and high temperatures. However, because there are so many polymorphs of yttrium disilicate, and the region of existence of γ-Y2Si2O7 in the Y2O3–SiO2 phase diagram is quite narrow, creating γ-Y2Si2O7 powder is difficult. As such, only a few studies have been performed on porous yttrium disilicate (examples here and here). In these studies, the authors describe three methods for preparing porous γ-Y2Si2O7 (polymeric sponge impregnation, in-situ foam-gelcasting, and in-situ foam-gelcasting-freeze drying) and two ways of optimizing the ceramic (solid solution strengthening and fiber reinforcement).

What will happen next?

In the future, the authors identify increasing strength as a main goal for porous rare-earth silicate research—a goal for research on many other porous materials as well. While part of this goal can be reached through optimized preparation methods, the authors also note that research on composite materials can help achieve this goal (a few composite studies are discussed throughout the article).

They keep their conclusion short and simple: “In conclusion, porous rare earth silicate ceramics and their composites are excellent potential materials for high-temperature thermal insulators.”

You can’t ask for a better summary than that!

The open-access paper, published in Journal of the Korean Ceramic Society, is “Progresses on the optimal processing and properties of highly porous rare earth silicate thermal insulators” (DOI: 10.4191/kcers.2018.55.6.12).