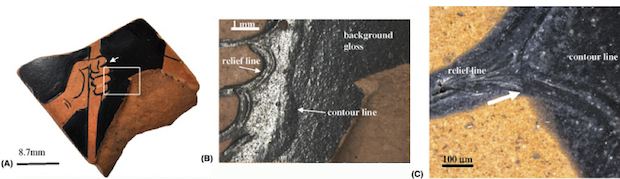

Optical images of a red-figure pottery fragment from Athens circa 700-500 BC. The black gloss results from a clay slip reaction to alternating oxidizing and reducing atmospheres during firing. Black gloss is shown in three regions: the relief line, the contour line, and the background. Credit: Walton, GCI; JACerS–Wiley.

The first ceramic engineers were potters whose innovations were critical to the transformation of ancient cultures from hunter-gatherers to agrarian societies. By the 6th to 4th centuries BC, the agrarian lifestyle was firmly established and so was pottery making as an industry. The archaeological record emerging from that time period in Athens, Greece suggests a robust industry that produced about 2 million fine ceramic pots per year and employed 1–3 percent of the urban Athenian population, according to a recent article in Archaeology, the magazine of the Archaeological Institute of America. Even then, the pots were considered works of art created by gifted artisans and were prized in the region.

About 400,000–800,000 artifacts from the era survive—that’s only 0.25–1 percent of the estimated total production. It is enough, though, to pique the interest of today’s culture sleuths, such as Marc Walton, associate scientist at the Getty Conservation Institute in Los Angeles, Calif. and lead author of a new paper in the Journal of the American Ceramic Society on the science behind firing the pots.

The work evolved from a 2005 exhibit at the J. Paul Getty Museum called “The Colors of Clay” about the colors used to decorate ancient Greek pottery. Walton’s GCI team was asked to analyze the black gloss that is common on these pots. “To our surprise we found that these clay materials showed more chemical variations than we had expected,” he said in an email. These initial results led to a larger project funded by the National Science Foundation with partners from industry and academia.

But, before I get into the details of the paper, some context is needed.

The imagery on the pottery from the era tells us much about what mattered to the ancient Athenians, their mythologies, and how they lived. The early fine ware pottery has distinctive black figures on a red background. The black-on-red style emerged around 700 BC. Later, around 530 BC, a new red-on-black decoration style emerged. Although the figures, whether red or black, look painted on, they are not glazes but clay-based slips. Key to both styles is how the so-called black gloss forms, and that involves some pretty sophisticated materials science.

The black gloss develops in response to alternating oxidizing and reducing atmospheres in the kiln during firing. The decoration figures are painted onto dried pots with clay slip, which has much finer-sized clay platelets than the clay used to make the body of the pot. During the reducing atmosphere segment of the firing, red hematite (Fe2O3) in the clay reduces to black magnetite (Fe3O4) and hercynite (FeAl2O4), which is also black. The slip-painted areas densify more thoroughly than the coarse-grained bulk areas, which makes the slip-painted areas impervious to reoxidation. When the kiln atmosphere is made oxidizing, the less dense regions reoxidize to form Fe2O3 and its characteristic red color, but the slip-painted regions remain black.

To make black-figure pottery, artists painted figures onto pots. To make red-figure pottery, artists painted the background such that a figure was left behind (similar to Michelangelo’s famous quip, “I saw the angel in the marble and carved until I set him free.”) The black background for the red-figure pottery was applied with three painting techniques: an outline, called a “relief line;” a “contour line,” which compares to the cut-in line painters apply around windows and doors; and finally, the background.

Several hypotheses have emerged about the firing scheme, and one unsolved mystery is whether the pottery was fired in a single, multistep firing or subjected to multiple firings. Walton and his team studied red-figure pottery sherds with some highly sophisticated materials characterization tools, analyzing the materials and compositions to gain insights into the ancient firing processes.

The team turned to Aerospace Corp., located in nearby El Segundo, Calif., for scanning transmission electron microscopy characterization. “Aerospace was an ideal partner because they have considerable expertise in reverse engineering of materials. This is essentially what we are attempting to do in this project—reverse engieer ancient Athenian pottery,” says Walton. GCI researchers also worked with scientists at the Stanford Synchrotron Radiation Lightsource (Menlo Park, Calif.) to characterize the three types of black gloss regions using X-ray microscopy.

The microscopy showed that the relief line is iron-spinel nanoscale crystallites suspended in a silica-rich glassy matrix, whereas the contour and background regions have a much higher degree of crystallinity. According to the paper, the microstructure of the relief line “suggests that this portion of the decoration underwent a very different degree of vitrification than the adjacent contour line and background slip regions, which exhibit only partial vitrification of the clay matrix.” However, the chemical compositions of the relief, contour, and background regions are very similar, leading the researchers to conclude that the morphological differences trace back to different thermal histories: “… the different degree of melting in the relief line seems to indicate it was subjected to a hotter temperature, thus necessitating more than one firing of the sherd.”

An advantage of the multiple firing process is that the slip could be applied in several steps, perhaps allowing for sharper edges and better detail in the figures.

The authors acknowledge that it is still possible that pots from the era were fired with a single, multistep process, but this study shows that at least some potters employed a multiple firing process. “The workshop practices of the Athenian potter thus appear to be significantly more complex than previously thought,” they conclude.

Had the Athenian artisans been contemporary, we probably would refer to them as nanotechnologists, and indeed, the researchers had access to a unique characterization tool that is used today to unlock materials’ nanomysteries—the synchrotron lightsource.

The Art, Archaeology and Conservation Science Division of ACerS, is hosting a workshop Oct. 1–2 at the SSRL called “Using X-rays to Analyze Cultural Heritage.” (Walton is vice chair of AACS.) There will be talks on using X-ray microscopy to study pigments, hidden layers in paintings, glazes, and ancient Roman pottery (terra sigillata).

Besides content for the art and archaeology scientists, there will be content for “traditional” scientists and engineers. Organizers have arranged three tutorials that will be useful to anyone who uses this tool. For example, I can imagine the UHTC community might find these tutorials very useful for getting a better understanding of how the synchrotron can help with evaluating the phase evolution dynamics of those materials. The tutorials are:

- Sample Preparation, XRF mapping, Region of interest masking using bivariate scatter plots, use of MCAs for data-analysis, PCA Analysis, Micro-tomography

- XANES and EXAFS at different edges (S, Fe, Cu, etc.)

- Multi-energy Mapping

The workshop is open to all interested parties, but space is limited.

Also, ACerS is offering a free year of membership in the AACS with new and renewing ACerS memberships. Join ACerS and the AACS Division to continue the tradition of ceramic science innovation through art!

Full details of the GCI work are in ”Material evidence for multiple firings of ancient Athenian red-figure pottery,” by Walton, et al., Journal of the American Ceramic Society (DOI 10.111/jace.12395)