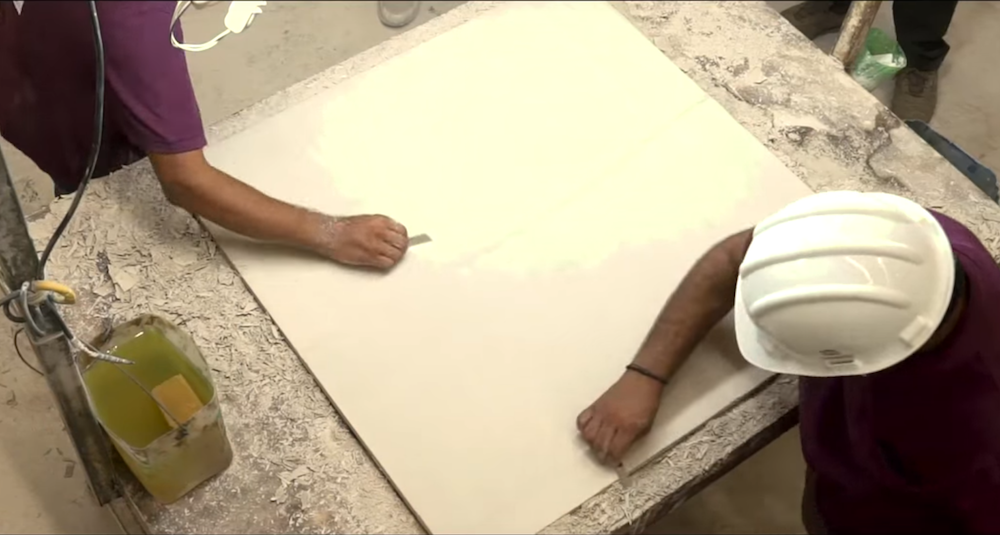

[Image above] Workers shape a ceramic tile at a manufacturing plant in Morbi, Gujarat, India. Credit: Ceramix Expo 2019, YouTube

From ghost flights to quarantined cruise ships, the effects of the rapidly-spreading novel coronavirus on the travel industry are overwhelmingly apparent to anyone watching the news. But the coronavirus’s effects on other aspects of society are just as significant, affecting everything from science conferences and sports festivals to global financial markets.

There are countless ways the coronavirus affects the global ceramic and glass communities, although currently ACerS meetings are not included in those effects (all upcoming ACerS meetings are expected to take place as scheduled). But one ceramic market in particular is experiencing a noticeable shift due to the virus—the global ceramic tile industry.

China is the world leader in manufacturing ceramic tile. In 2018, the country produced roughly 5.7 billion square meters of ceramic tile, according to a Statista graphic. Compare that to the 13.1 billion square meters produced globally, as stated in a recent ACIMAC Research Department report, and you’ll see China produced more than 40% of all ceramic tiles manufactured that year.

India comes in a distant second to China, as the Statista graphic shows the country producing only about 1.15 billion square meters in 2018. But the coronavirus presents India with a chance to close that gap.

Morbi, a region in the Indian state of Gujarat, alone accounts for about 90% of the total production of ceramic products in India. Last year saw difficulties for tile makers in Morbi, including more than 400 of the 550 wall tile plants being closed due to a coal gasifier ban and a drop in production due to lower domestic demand caused by a sluggish real estate market and poor retail sales.

Over the past couple months, however, exports from China stopped as the country focused on tackling the coronavirus—which gave tile makers in Morbi an opening.

“We are expecting a 10% increase in exports from Morbi as result of current crisis in China. Some of the tile makers have already started exporting to Europe and African countries,” says Nilesh Jetpariya, president of Morbi Ceramic Association, in a Financial Express article.

If the coronavirus continues to affect Chinese exports for a prolonged time, however, India may face shortages in raw materials, in particular the abrasives needed for polishing vitrified tiles. If that happens, “ceramic units will have to import from Spain, which would be costlier,” says Dinesh Sadsania, a leading exporter of ceramic products from Morbi, in the Financial Express article.

The video below is from an ABP Asmita newscast on the situation. (The video is spoken completely in Gujarati, the local language.)

Credit: ABP Asmita, YouTube

For people who do not speak Gujarati but are interested in learning more about Morbi, check out the video below, which gives a brief history and current state of ceramic manufacturing in Morbi.

Credit: Ceramix Expo 2019, YouTube