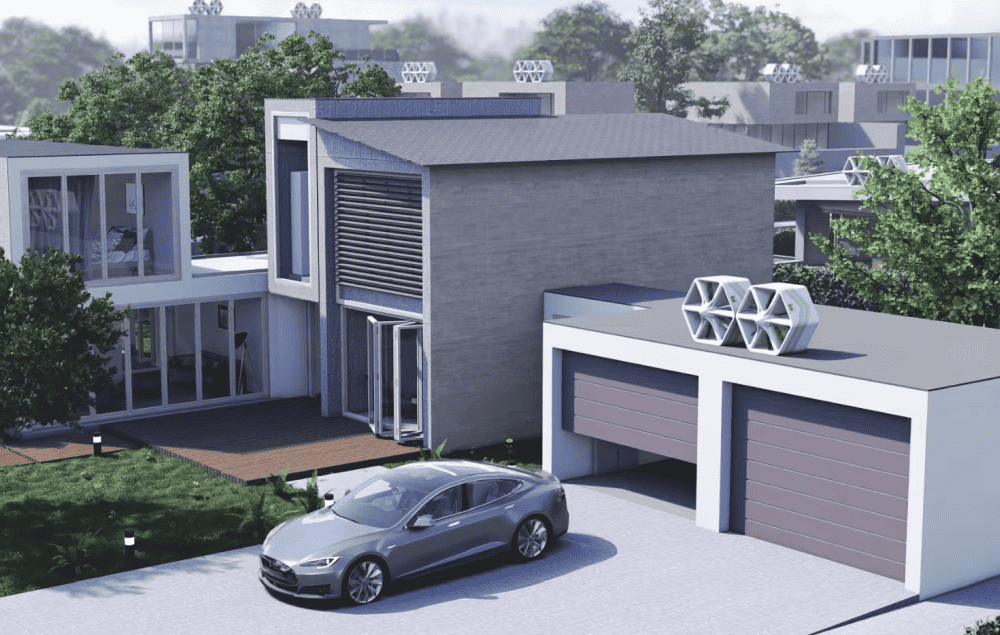

[Image above] A rendering showing how Katrick Technologies’ honeycomb-shaped bladeless wind generators could be installed in urban settings. Credit: Katrick Technologies, YouTube

The size of wind turbines has grown dramatically in the past two decades, in terms of both height and blade length. While this size increase means each turbine can produce more electricity, it also makes transportation and installation of turbines more difficult, thus hindering their deployment in certain locations.

Some companies have developed smaller, alternative devices for harvesting wind energy that can be more easily deployed in urban areas. For example, Spanish technology startup Vortex Bladeless SL offers bladeless wind generators that range in height from 1 to 13 meters (3.3 to 42.6 feet), in contrast to the 98-meter (322-feet) height of current utility-scale land-based wind turbines.

Recently, news outlets have reported on the development of another bladeless wind generator design by Scottish technology startup Katrick Technologies. In contrast to the generators offered by Vortex Bladeless, which consist of a single vibrating column, the generators by Katrick Technologies embrace a honeycomb-shaped design.

Within each quadrant of Katrick’s compact hexagonal generator are airfoils that oscillate independently when exposed to wind. These mechanical oscillations are converted to energy, making the approach more efficient in less windy conditions.

On Dec. 14, 2023, Katrick announced that the honeycomb-shaped generator, which was developed in partnership with The Manufacturing Technology Centre, had completed the first stage of alpha testing at the University of Strathclyde. It exceeded expectations by producing 41.1 W of mechanical power at wind speeds of 10.2 m/s and achieved an overall efficiency of 6.85%.

The generator is currently validated to technology readiness level (TRL) 5 by the University of Strathclyde. Katrick aims to have the generator validated at TLR 6 during the next stage of testing.

“We look forward to continuing our work with [Katrick] to help commercialize their invention and accelerate society’s transition to sustainable energy,” says Steve Nesbitt, chief technologist for the built environment at The Manufacturing Technology Centre, in the Katrick press release.