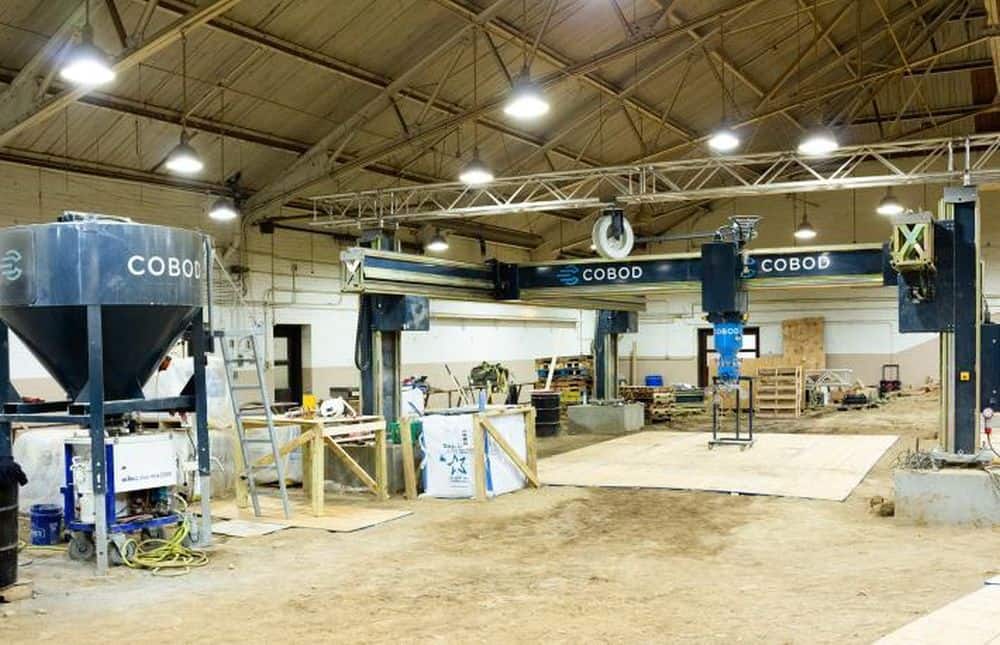

[Image above] COBOD International’s BOD2 printer at The Ohio State University’s Center for Design and Manufacturing Excellence. Credit: The Ohio State University

By Laurel Sheppard

With housing shortages rampant in countries around the world—and with the houses that are available unaffordable for many—the construction industry is considering alternative building materials and methods to make housing more affordable.

3D printing is one approach gaining steam in the construction industry. Compared to conventional construction methods, 3D-printing technologies allow companies to develop complex shapes while using less material. It also aids in less material wastage because failed prints can be reused as raw material in later printing stages.

Though local building codes are slowing the adoption of 3D-printing technologies in certain areas—a slowdown that some states are addressing—several companies have started making names for themselves in the 3D printing for construction space.

For example, Denmark-based manufacturer COBOD International specializes in construction-grade 3D printers. The company’s modular BOD2 printer has been used globally for projects involving residential houses, industrial constructions, and commercial buildings.

Just in the past year, the BOD2 printer was used to construct several record-breaking buildings in the United States, including

- California’s first fully code compliant 3D-printed house, which encompassed 1,200 square feet;

- World’s largest 3D-printed building, a 10,000-square-foot luxury horse barn in Florida; and

- Largest 3D-printed residential building in the U.S., a 4,000-square-foot, two-story house in Texas.

To further expand the use of 3D printing in construction, however, will require training the next generation of builders on these techniques. At The Ohio State University, the BOD2 printer will now play a role in this education thanks to a new partnership between the university’s Center for Design and Manufacturing Excellence (CDME) and 3D-printing construction company Pantheon Innovative Builders.

In January 2023, Youngstown, Ohio-based Pantheon delivered a BOD2 printer to CDME to serve as the pivotal piece of equipment in their new research partnership. It is the first large-scale concrete construction printer in Ohio and one of fewer than 10 at universities worldwide. It adds to CDME’s already impressive additive manufacturing capabilities, which include industrial 3D printers that can process metals, polymers, composites, biomaterials, and ceramics.

In a press release, Ben DiMarco, additive manufacturing technologist at CDME, says the university “knew we needed to bring this unique capability to our lab at CDME to continue to introduce new technology with our students and push the boundaries of additive manufacturing in the United States.”

The research partnership will include testing; print demonstrations; experimental learning for students; and the creation of a workforce development training curriculum, which can count as credit toward post-secondary or trade education. COBOD will provide on-site support with machine startup, training, and material development.

To accommodate the specific needs of 3D-printed construction, CDME has built a team of experts from multiple departments at the university. For example, Lisa Burris, assistant professor of civil, environmental, and geodetic engineering, will be conducting research with her team that centers on testing the performance of the 3D-printed construction material in various environments.

In the press release, Pantheon CEO Ryan Kelly says the company is “extremely excited” for this opportunity to work with CDME and COBOD.

“This partnership will help us create a model to reimagine, retrain and recruit the future construction workforce,” he says.

In April 2023, CDME hosted an event to let the broader university community know about the new printer and partnership. While the event spurred more conversations about collaboration within 3D-printed construction, DiMarco says, “The door for collaboration is always open.”