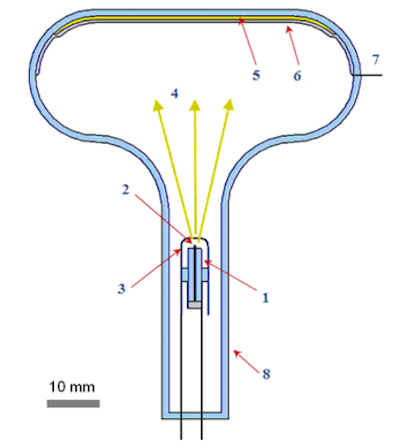

[Image above] In addition to LEDs, cathodoluminescent lamps offer a clean and energy-efficient alternative to incandescents and compact fluorescent lamps. Credit: Moscow Institute of Physics and Technology

In August 2017, the United Nations Minamata Convention on Mercury came into effect. Named after the Japanese city where a horrific mercury poisoning disaster took place in the 1950s, the convention aims to phase out the manufacture, import, and export of products containing mercury by 2020.

One product specifically called out by the convention is compact fluorescent lamps (CFLs). In the late 1990s and early 2000s, CFLs were expected to replace traditional incandescents because they use about 75% less energy and last about 10 times longer, according to the United States Department of Energy’s website. However, because mercury is an integral part of CFLs, the convention places restrictions on CFL production.

In some ways, the Minamata Convention will not heavily affect the lighting industry because society has already started shifting away from CFLs. Since the 2010s, light emitting diodes (LEDs) have continued to gain on CFLs in the lighting market, and some countries were actively trying to phase out CFLs before the convention came into play.

Yet as incandescents and CFLs are put aside in favor of more energy-efficient and environmentally friendly LEDs, we are slowly placing all our lighting needs in one basket—a basket that has some holes.

The most well-known drawback of LEDs is that they are sensitive to temperature. High temperatures can reduce LED efficiency and service life, limiting the use of LEDs in high-temperature applications.

Additionally, LEDs contain “critical” raw materials, such as gallium, indium, and some rare earth elements (especially yttrium and europium). That means LED production hinges on access to these materials, which are more likely to face supply constraints as nascent green-energy technologies such as solar cells become more popular and require a larger share of the critical raw materials supply.

Are there other clean and energy-efficient alternatives to incandescents and CFLs? One promising possibility is cathodoluminescent lamps (CLLs).

Compared to LEDs, CLLs do not contain indium and gallium, rare earths are not critical to manufacture them, and they are not sensitive to ambient temperature. Additionally, CLLs exhibit high light output, long service life, and do not contain mercury!

CLLs rely on the same principle that powered cathode-ray tube (CRT) televisions. In cathodoluminescent technologies, a vacuum tube contains a negatively charged electrode (cathode) at one end and a positively charged, phosphor-coated electrode (anode) at the other. The cathode serves as an “electron gun” from which emitted electrons accelerate toward the anode at the opposite end, striking the phosphor and generating light.

Although CRT televisions are today often associated with hazardous waste, the science behind cathodoluminescence technology is not inherently toxic—it was how those old televisions implemented the technology.

In old color CRT televisions, phosphors were commonly made from highly toxic elements, such as cadmium, and the vacuum tube was made of leaded glass. However, today there are numerous options for nontoxic phosphors, and CLLs do not use leaded glass.

Designing CLLs for general lighting

Though CLLs hold a lot of potential, designing CLLs for general lighting is challenging. Specifically, designing field emission cathodes have presented the largest hurdle.

Cathodoluminescence takes place in one of two ways: thermionic emission or field emission. In thermionic emission, the cathode is heated to make it emit electrons. Old CRT televisions used thermionic emission, which is why it could take several minutes for the screen to “warm up” and display images. In contrast, field emission causes the light to switch on instantly by placing the cathode in a strong electric field.

The tip of a field emission cathode consists of a set of nanosized protrusions to concentrate the electric field. But designing these tiny edges can be difficult, as researcher Mikhail Danilkin from Lebedev Physical Institute of the Russian Academy of Sciences (LPI RAS) explains in an email.

“Emitted electrons are accelerated and inevitably create some amount of positive ions by bombardment of anode materials. These positive ions are accelerated and move in opposite direction,” Danilkin says. “The destructive action of accelerated positive ions on the tiny sharp edges of field-emitting cathode is a problem for many known materials.”

“Another problem is a ponderomotive force which breaks the edges at high emission current,” he adds. “A special design of cathode material is required to make it stable against these two destructive factors.”

Several previous studies have tried to use carbon nanotubes to create cathode protrusions, but in a new study led by Evgenii Sheshin, first author and deputy chair of vacuum electronics at Moscow Institute of Physics and Technology (MIPT), Danilkin and colleagues at MIPT and LPI RAS looked at carbon fibers instead—and their approach paid off.

In an MIPT press release, Sheshin explains why carbon fibers work well as the cathode material.

“This carbon is not used merely as a chemical, but rather as a structure,” he explains. “We found a way to fashion a structure from carbon fibers that is resistant to ion bombardment, outputs a high emission current, is technological, and affordable in production.”

In their paper, the researchers explain these field emission cathodes based on carbon fiber exhibit long service life (>10,000 hours) and can achieve light output of up to 110 lm/W (LEDs are typically 40–100 lm/W). The researchers also developed a compact power source for their CLL that fits around the glass light bulb with minimal effect on its size.

“Owing to these features, the CLLs can effectively complement the LED lamps as environment-friendly light sources,” they conclude.

In the future, the researchers plan to create a laboratory to scale up their studies and to develop ultraviolet CLLs.

The paper, published in Journal of Vacuum Science & Technology B, is “Prototype of cathodoluminescent lamp for general lighting using carbon fiber field emission cathode” (DOI: 10.1116/1.5070108).