[Image above] Australian researchers led by RMIT University used acoustic waves to create oriented and activated MOF powders in a one-step process. The microchip used to produce high-frequency sound waves can be seen above next to the acoustically created MOF. Credit: RMIT University

If I asked a room full of people if they have heard of graphene, scientists and nonscientists alike would doubtless raise their hands. But if I asked those same people if they have heard of MOFs, the affirmatives would likely be far less widespread.

Metal-organic frameworks, or MOFs, are incredibly versatile and porous nanomaterials made from highly ordered 3D coordination networks of metal ions and organic ligands. Ever since Yaghi et al. popularized the term MOF around 1995, research on MOFs has garnered significant attention due to the material’s porosity, which allows diffusion of guest molecules into the bulk structure and thus makes MOFs ideal for storage, separation, and catalysis applications.

The title of a 2018 Scientific American article aptly summarizes just how important scientists feel MOFs will be for future technology: “You’ve probably never heard of MOFs, but they could be as important to the 21st century as plastics were to the 20th.”

Despite holding such huge potential, MOF synthesis presents a challenge to realizing large-scale MOF production.

Since the 1990s, researchers have investigated various techniques to synthesize MOFs, including hydrothermal, solvothermal, microwave, sonochemical, and electrochemical synthesis. However, due to inhomogeneities in the diffusion process, these synthesis techniques commonly involve drawbacks such as random orientation, polycrystallinity, and plentiful defects within the MOF structure.

Additionally, unreacted solvents often become trapped within the pores during synthesis. So, subsequent post-synthesis chemical or thermal activation processes are required to remove these unreacted solvents, which places a significant practical limitation on large-scale production of MOF powders.

In January, I wrote a CTT article discussing a coffee-ring-based technique for MOF synthesis that tackled one of these synthesis challenges by offering a way to grow large-area MOF films with an oriented (rather than random) structure. Now, a new open-access study published in Nature Communications describes another technique capable of growing oriented MOF films—while also tackling another synthesis challenge as well.

Researchers from RMIT University in Australia, along with colleagues from the University of Melbourne and Commonwealth Scientific and Industrial Research Organisation (CSIRO), developed a one-step synthesis and activation technique for MOF powders that both ensures a high degree of orientation and removes the need for further post-processing steps. Additionally, the technique takes place at room temperature, is environmentally friendly, and can produce MOFs in as little as 5 minutes!

What is the secret to such efficient synthesis? One word—acoustics.

“Our acoustically-driven approach avoids the environmental harms of traditional methods and produces ready-to-use MOFs quickly and sustainably,” says Heba Ahmed, a postdoctoral researcher at RMIT, in an RMIT press release. “The technique not only eliminates one of the most time-consuming steps in making MOFs, it leaves no trace and can be easily scaled up for efficient mass production.”

For their study, the researchers developed an acoustomicrofluidic synthesis platform that uses a microchip to produce high-frequency sound waves. In the press release, coauthor and acoustic expert Amgad Rezk explains these sound waves, though not audible to humans, can be used for precision micro- and nanomanufacturing.

“At the nanoscale, sound waves are powerful tools for the meticulous ordering and maneuvering of atoms and molecules,” Rezk says.

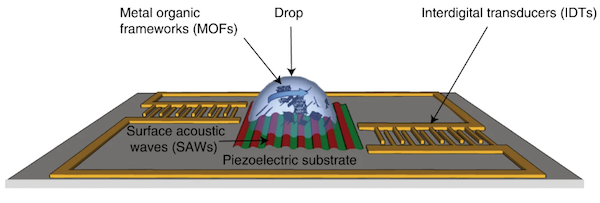

The acoustomicrofluidic synthesis platform is a piezoelectric substrate made from lithium niobate (LiNbO3) with a pair of interdigital transducers placed on either side. According to the paper, “[the transducers] are deliberately patterned off-center on the substrate in order to break the symmetry of the opposing surface acoustic waves.”

The researchers placed a drop of an ethanol–water solution containing a copper precursor and trimesic acid on the substrate. The drop was then subjected to acoustically driven microcentrifugation at varying acoustic intensities to induce nucleation and subsequent crystallization. (The researchers also created iron-based MOFs.)

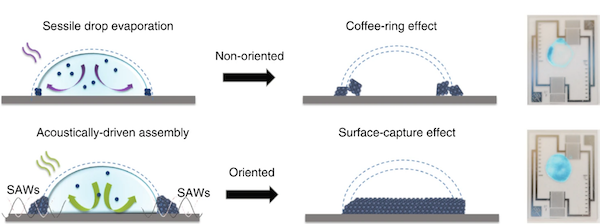

Interestingly, the researchers also mention the coffee-ring effect, which was the basis behind the study I covered in the January CTT. They postulate that the coffee-ring effect was the mechanism behind differences observed in their control and experimental groups.

In the control group, no acoustic waves were applied to the setup, meaning the liquid drop was left to evaporate on its own. In stark contrast to the experimental group, control-group crystals showed no apparent orientation preference.

According to the researchers, “slow solvent evaporation leads to a weak convection cell in the drop, which transports the solute molecules to its contact line, where they precipitate to form a ring of crystals akin to coffee-ring stains. The slow diffusion-dominated process then culminates in a dilute solute concentration in the contact line region, and therefore the crystals that form lack long-range ordering.”

In contrast, when the drop is subject to acoustic waves, “the microcentrifugation flow that arises drives fast turbulent convective transport of the solute molecules to the contact line, whose oscillation smears out the coffee-rings, leading to homogeneous deposition of successive stacks of solute monolayers.”

In their conclusion, the researchers recap the success of their experiments and discuss what their setup could mean for industry. “[W]e note the potential of the setup to be scaled to achieve industrially-relevant production rates by employing a large number of devices in parallel … thus making the platform an attractive alternative for environmentally-friendly large-scale MOF production for a vast array of applications.”

The open-access paper, published in Nature Communications, is “Acoustomicrofluidic assembly of oriented and simultaneously activated metal-organic frameworks” (DOI: 10.1038/s41467-019-10173-5).