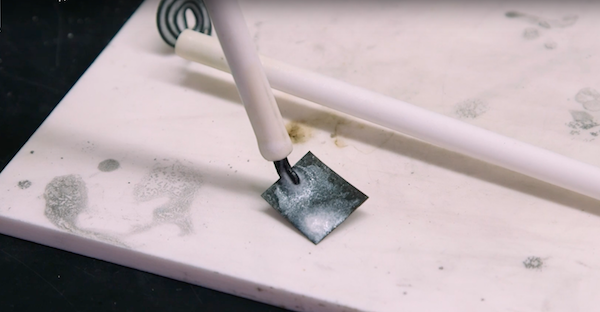

[Image above] Credit: Vanderbilt University, YouTube

It’s a known fact that carbon dioxide is one of planet Earth’s biggest nemeses.

CO2 exists in the Earth’s atmosphere, but it is needed for the lifecycle of plants. It is also a byproduct of metabolism in humans. And contrary to popular belief, a majority of CO2 emissions comes from natural sources such as oceans, volcanic activity, and animal and plant respiration.

Though we cannot control nature, we can take steps to reduce our own carbon footprint.

Scientists are currently exploring ways to recycle CO2 and one Canadian company is already doing it.

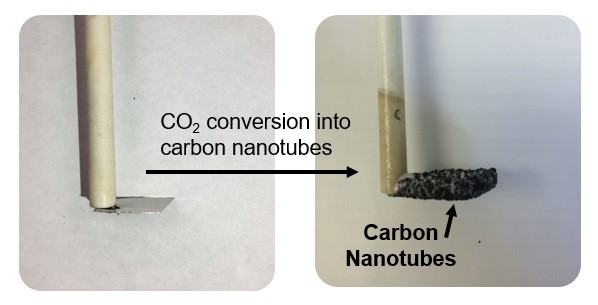

And now, researchers at Vanderbilt University are actually making something useful out of CO2—small-diameter carbon nanotubes.

Led by assistant professor of mechanical engineering Cary Pint, the team demonstrated that they could make carbon nanotubes (CNTs) out of carbon dioxide pulled from the air. But what’s significant is that the researchers were able to make them a lot cheaper than current methods.

“The cheapest carbon nanotubes on the market cost around $100-200 per kilogram,” interdisciplinary material science Ph.D. student and team member Anna Douglas says in a Vanderbilt University news release. “Our research advance demonstrates a pathway to synthesize carbon nanotubes better in quality than these materials with lower cost and using carbon dioxide captured from the air.”

Pint and his team developed small-diameter CNTs on a stainless steel surface using electrochemical synthesis from ambient CO2, according to the paper’s abstract. Initially, it wasn’t an easy process and the researchers encountered an obstacle: Ostwald ripening—a process in which nanoparticles grow larger in size, enlarging CNT diameters, which makes them less useful, according to the release. The researchers eventually solved this by fine-tuning the electrochemical parameters.

Credit: Vanderbilt University

“One of the most exciting things about what we’ve done is use electrochemistry to pull apart carbon dioxide into elemental constituents of carbon and oxygen and stitch together, with nanometer precision, those carbon atoms into new forms of matter,” Pint says in the release. “That opens the door to being able to generate really valuable products with carbon nanotubes.”

The success of their process led Pint and Douglas to start a company, SkyNano Technologies, with the goal of scaling the technology for manufacturing.

“What we’ve learned is the science that opens the door to now build some of the most valuable materials in our world, such as diamonds and single-walled carbon nanotubes, from carbon dioxide that we capture from air through our process,” Pint says.

“This science that we’ve developed and the ability to produce this material cost-efficiently is a really exciting step forward.”

The paper, published in Applied Materials & Interfaces, is “Toward Small-Diameter Carbon Nanotubes Synthesized from Captured Carbon Dioxide: Critical Role of Catalyst Coarsening” (DOI: 10.1021/acsami.8b02834).

Watch the video below to learn more.

Want to read more articles like this? Subscribe to the Ceramic Tech Today newsletter to continue to receive the latest news in the ceramic and glass industry right in your inbox! Visit this link to get started.