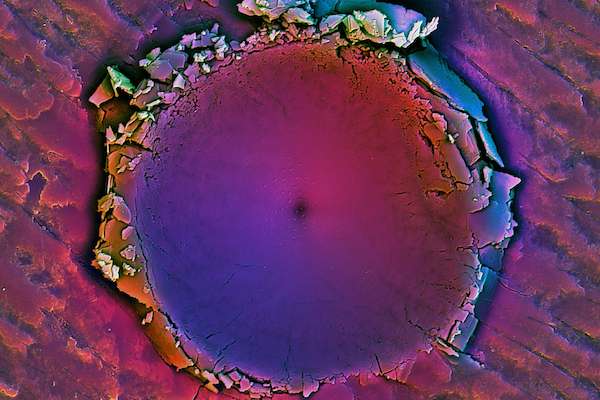

SEM image of the region surrounding an indentation made in a windowpane oyster seashell, showing the localization of damage to the area immediately surrounding the stress. Credit: Ling Li and James C. Weaver, MIT.

Earth has some pretty interesting tenants, many of which inspire us humans because of their extraordinary characteristics. I’ve reported before that the microstructure of super strong material nacre, or mother-of-pearl, has been an inspiration for less brittle glass.

New research shows that marine mollusks are continuing to inspire innovations, particularly in the way of ceramics.

Researchers from the French National Centre for Scientific Research (CNRS) report that nacre has inspired a new process for making stronger ceramics. The work, published in Nature Materials, successfully recreates nacre’s stacked nanobrick structure with ceramic materials.

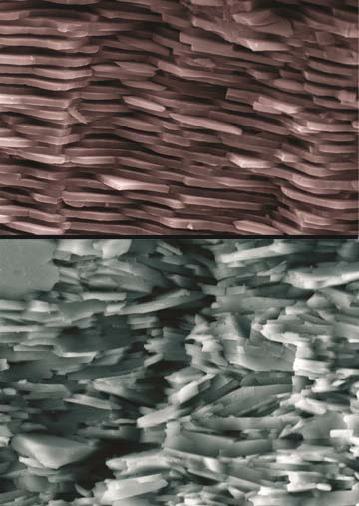

Structure of natural mother-of pearl (top) and the

synthetic mother-of-pearl (bottom), at the same scale. Credit: Sylvain Deville, Florian Bouville, LSFC.

The team used alumina powder suspended in water and froze the colloidal suspension, controlling the growth of the ice crystals to get stacked platelets resembling nacre’s sturdy microstructure (image left). A high-temp densification finalized the product, a ceramic that is ten times stronger than traditional alumina ceramic. “This is because a crack has to move round the alumina ‘bricks’ one by one to propagate,” states the CNRS press release. “This zigzag pathway prevents it from crossing the material easily.”

According to the paper’s abstract, the authors report “the fabrication of bulk ceramics without a ductile phase and with a unique combination of high strength (470 MPa), high toughness (22 MPa m1/2), and high stiffness (290 GPa)” that “retain their mechanical properties at high temperatures (600 °C).”

The process can be applied to any ceramic powder than forms platelets and thus could allow industrial scaling of the process, indicates the press release. It continues, “This bio-inspired material’s toughness for equivalent density could make it possible to produce smaller, lighter parts with no significant increase in costs. This invention could become a material of choice for applications subjected to severe constraints in fields ranging from energy to armor plating.”

The paper is “Strong, tough and stiff bioinspired ceramics from brittle constituents” (DOI: 10.1038/nmat3915).

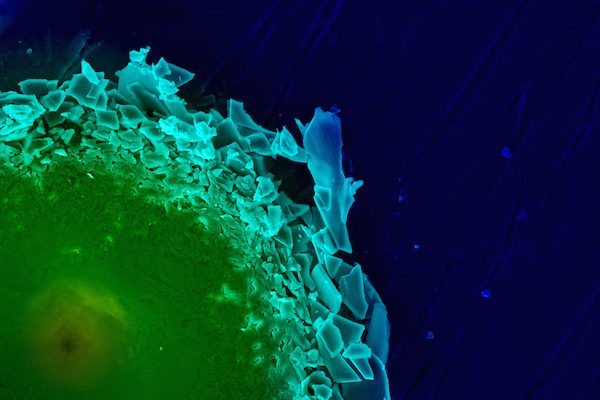

And although their inspiration comes from a different marine creature, researchers from MIT also have been bio-inspired to make stronger ceramics. Their creature of choice, Placuna placenta or windowpane oysters, have optically clear yet incredibly strong shells.

Windowpane oyster shells are composed of about 99% calcite, a traditionally brittle material, and 1% organic material, but are surprisingly strong. The MIT research, also published in Nature Materials, indicates that the strength again comes from microstructure, as the shells’ calcite is arrange in layered diamond-shaped crystals.

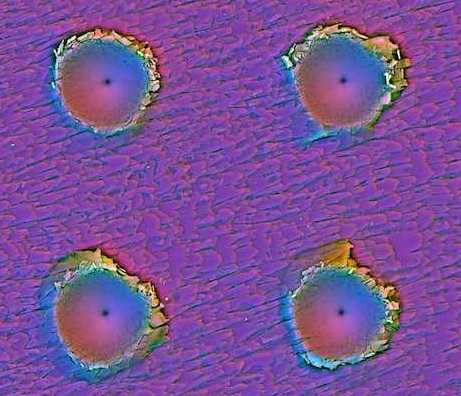

The researchers used indentation tests and high-resolution imaging to determine how precisely those crystals respond to deformation.

SEM image of the localized effects of four separate indentation tests on windowpane oyster shells. Credit: Ling Li and James C. Weaver, MIT.

As the MIT press release explains, “The material initially isolates damage through an atomic-level process called ‘twinning’ within the individual ceramic building blocks: A crystal breaks up into a pair of mirror-image regions that share a common boundary, rather like a butterfly’s wings. This twinning process occurs all around the stressed region, helping to form a kind of boundary that keeps the damage from spreading outward.”

This process then “catalyses a series of additional inelastic energy dissipating mechanisms such as interfacial and intracrystalline nanocracking, viscoplastic stretching of interfacial organic material, and nanograin formation and reorientation,” states the paper’s abstract.

The release suggests the research could aid future development of synthetic materials for both commercial and military applications, including protective visible shields and windows.

The paper is “Pervasive nanoscale deformation twinning as a catalyst for efficient energy dissipation in a bioceramic armour” (DOI: 10.1038/nmat3920).

Feature image credit: Ling Li and James C. Weaver, MIT.