Materials that can display superconductivity are extremely rare in nature, and to date, no naturally occurring mineral was known to display unconventional superconductivity. Researchers led by Ames National Laboratory discovered that miassite, which previously was identified as a superconductor, actually displays unconventional superconductivity.

Read MoreUnleashing ceramic potential through root cause analysis, plus more inside March 2024 ACerS Bulletin

The March 2024 issue of the ACerS Bulletin—featuring methods and procedures to determine the root cause of material failures and behavior—is now available online. Plus—Zachariasen and the Manhattan Project.

Read MoreExposure to high-energy radiation is a main health concern for future human space travel. Researchers at the University of Maryland, Baltimore County investigated the effects of high-energy radiation on hydroxyapatite, an important bone material.

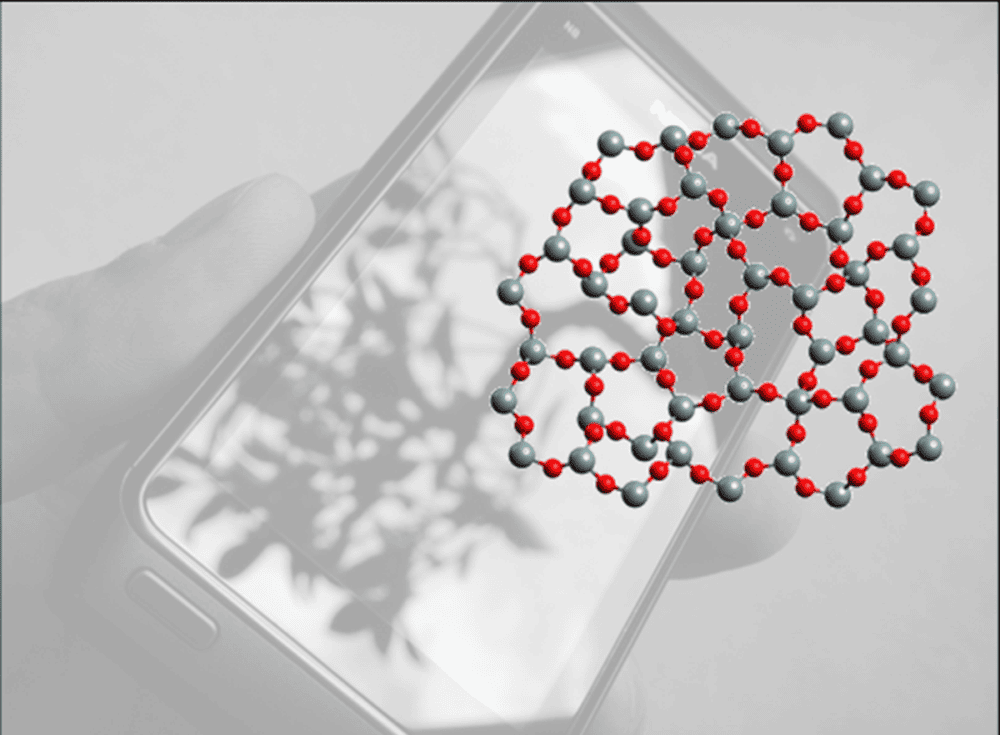

Read MoreFragility is a key glass property that helps manufacturers optimize processing parameters during glass fabrication. Measuring fragility, though, is a labor-intensive and time-consuming process. Identifying structural parameters that correlate with fragility could make predicting this property easier, and a new study led by Corning researchers reveals a correlation with the medium-range atomic ring structure.

Read MoreThe eggs of brood parasitic birds have evolved in response to host bird defense strategies. An international group of researchers used imaging techniques and conceptual frameworks from the field of grain boundary engineering to understand how structural features affect eggshell strength.

Read MoreMaterials scientists often use grain size as the determining variable when correlating a ceramic’s structure with its properties. But the morphology and orientation of the grains can also significantly affect a material’s properties. Researchers in China developed a framework that can correlate a material’s structural hierarchy with its properties, and their latest paper explores the potential of linking this framework to Vickers hardness.

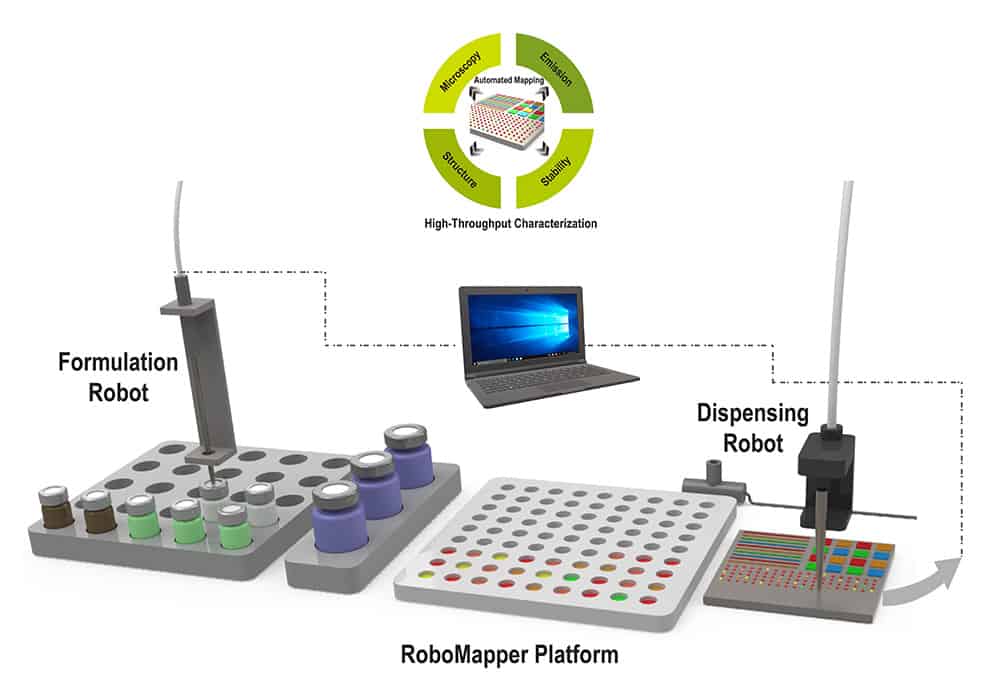

Read MoreAutomating experiments can help speed up the materials development process. Researchers led by North Carolina State University developed a new high-throughput automated testing system that deposits multiple samples on the same substrate, thus saving time and energy.

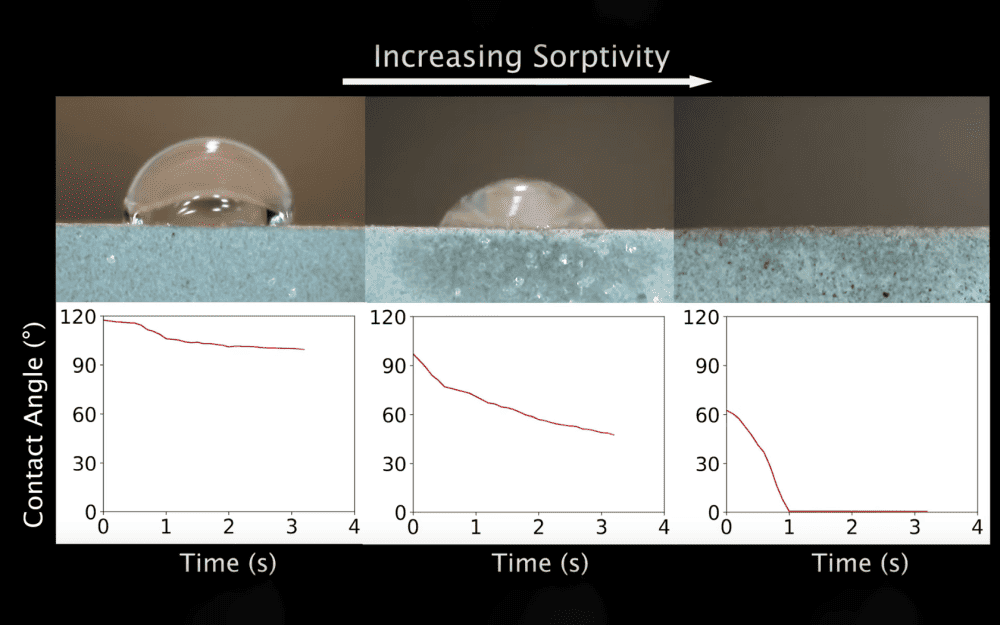

Read MoreTesting the durability of building materials is typically a slow, tedious, and labor-intensive process. Researchers at the University of Illinois Urbana-Champaign used computer vision to develop a fast and affordable method for testing cement durability, demonstrating the potential to improve quality control in the cement industry through automated methods.

Read MoreVerifying the purity of ultrahigh-purity materials can be a challenge. Researchers in Italy and Norway developed a new analytical protocol based on laser ablation paired with inductively coupled plasma mass spectrometry to determine the purity of silicon carbide.

Read More