Researchers at Chalmers University of Technology have devised a way to contract graphene to kill bacteria on the surface of biomedical implants, using a thin layer of atomically thin graphene spikes to slice bacteria apart.

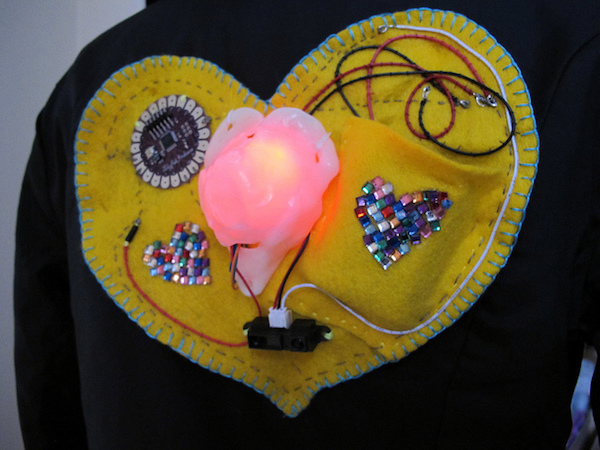

Read MoreA team of materials scientists at the University of Massachusetts Amherst has developed a way to turn fabric into a conductor of electricity that is capable of powering small electronics. A vapor deposition method turns woven fabrics into electrical conductors without changing properties of the fabrics.

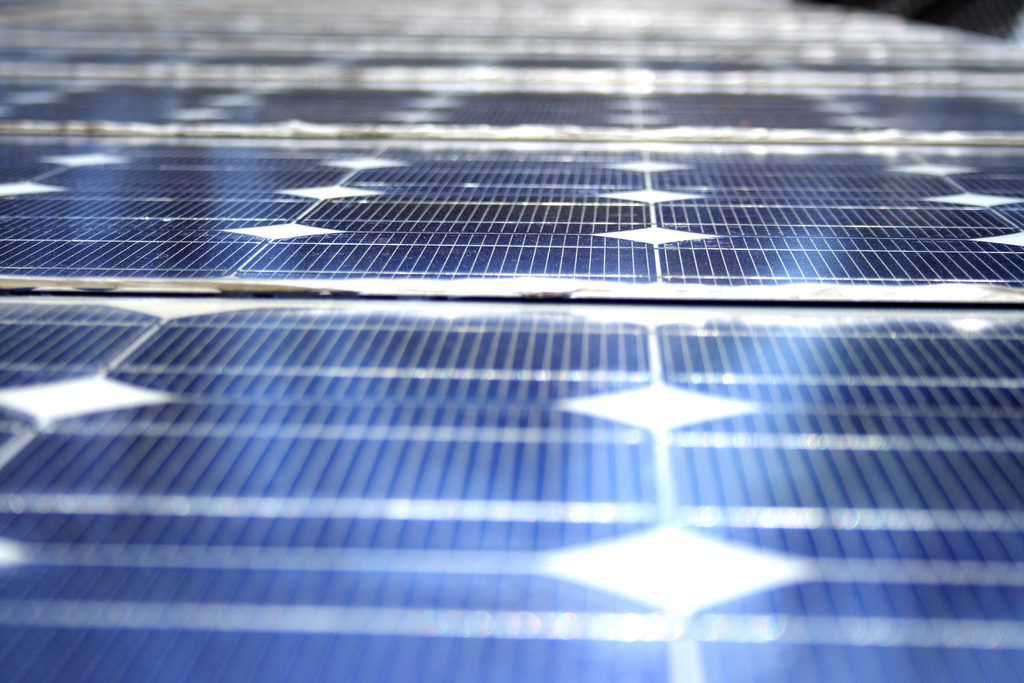

Read MoreScientists at Pennsylvania State University are working on a new high-pressure technique that could open the door to more cost-effective production of large, flexible solar panels.

Read MoreIRradiance Glass earns chalcogenide grant, systematic risk in mineral markets, and more ceramics and glass business news of the week for November 20, 2015.

Read MoreA multiwall carbon nanotube with triple-wall, “arm chair” morphology. Global production capacity of MWNTs is about 4.5 kilotons per year. Credit: Wikimedia. Twenty years is the figure cited in Materials…

Read MoreNo more broken glass? Theoretical work by researchers at Rice University shows the potential for doubling the strength of glass. Credit: Rice University. Glass is one of the intrinsically strongest…

Read MoreCheck ’em out: The CVD system coats solar panel substrates in the cycle. Credit: Fraunhofer IST. New processes for cost-efficient solar cell production The photovoltaic industry is pinning its hopes…

Read More